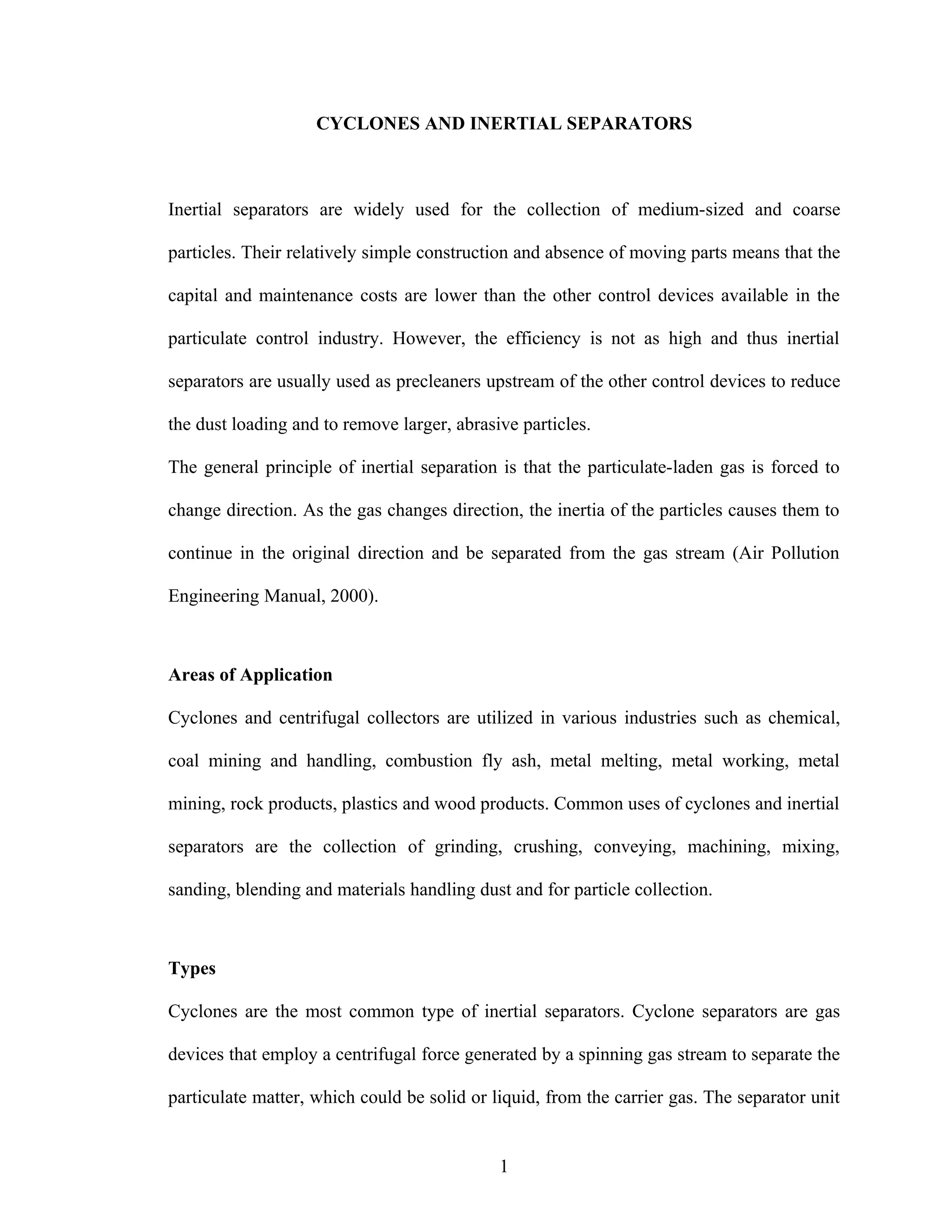

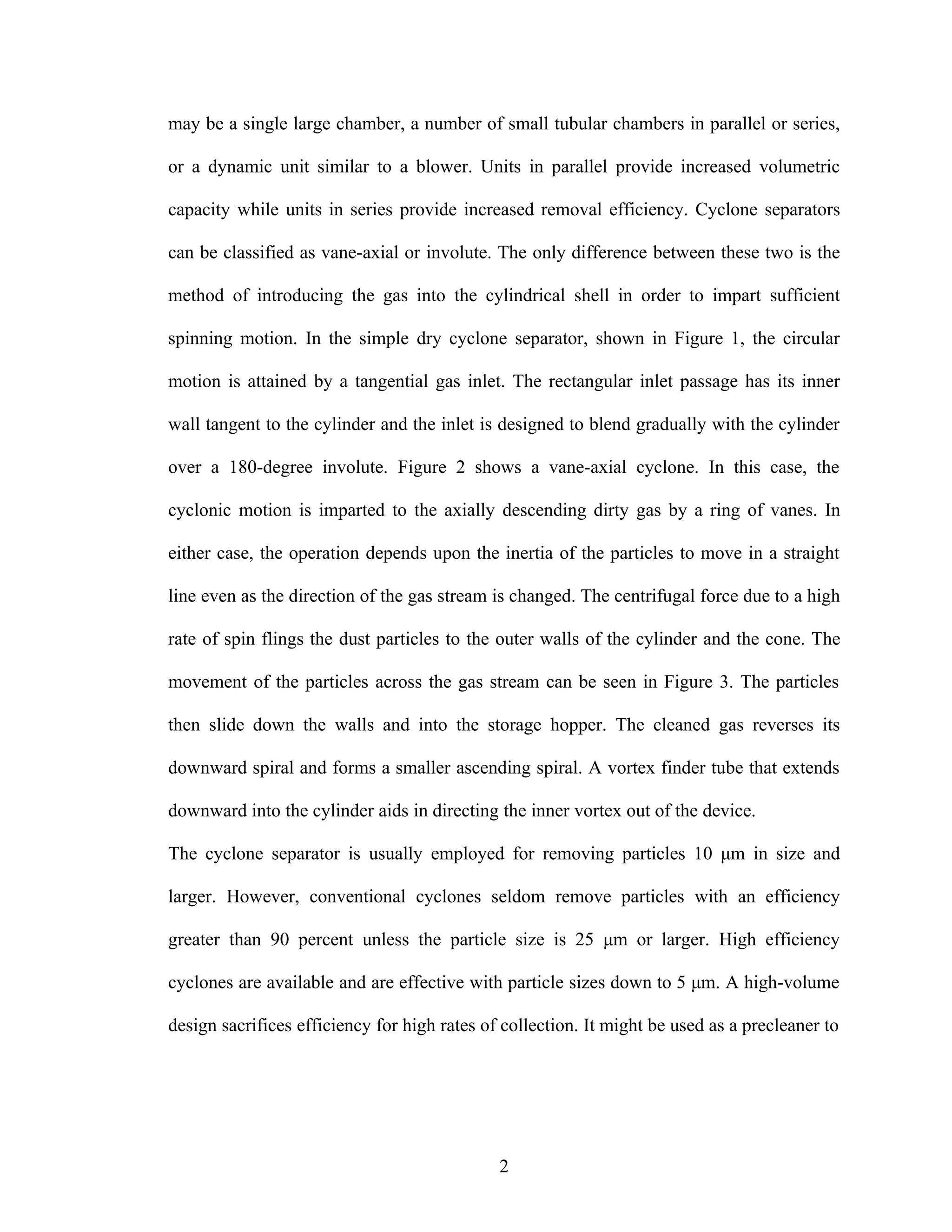

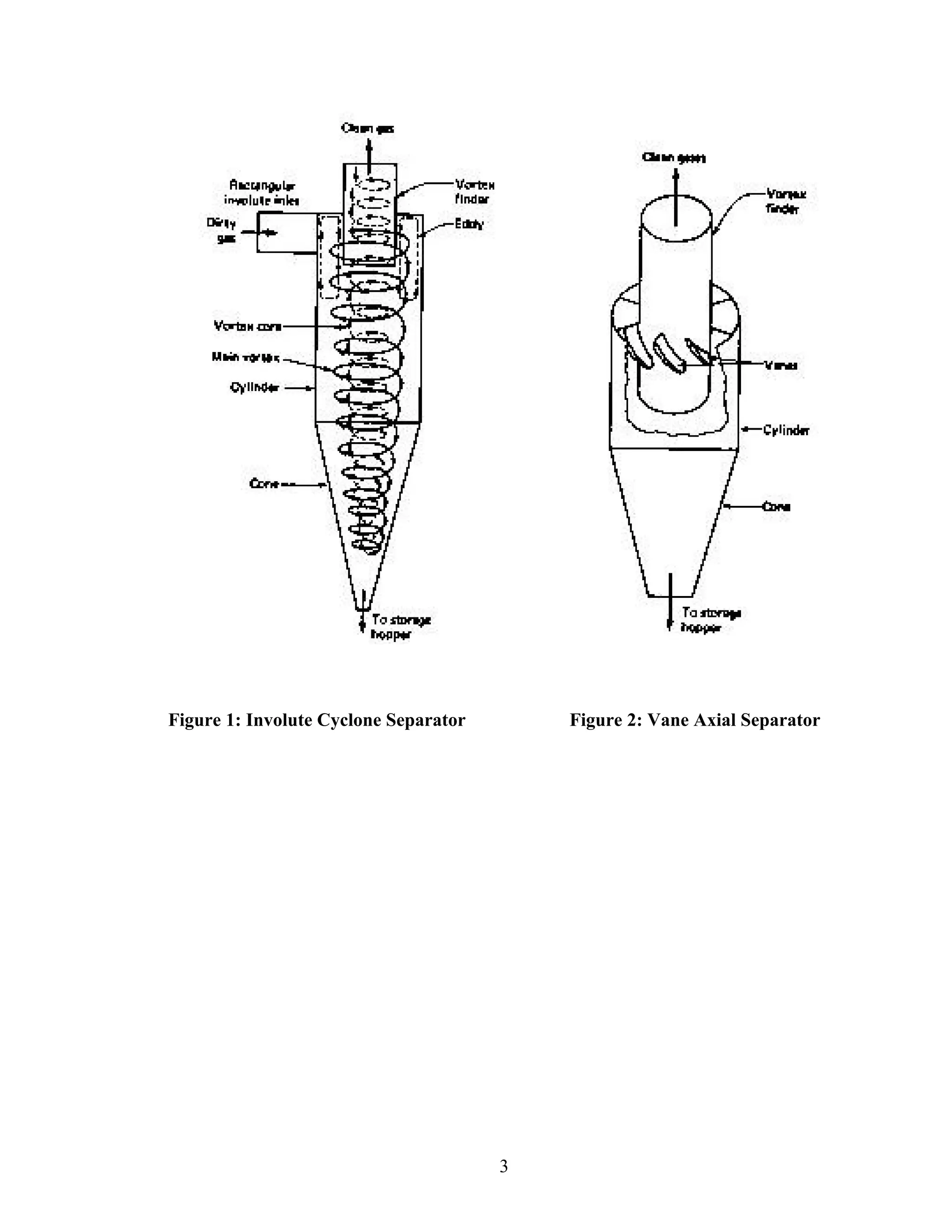

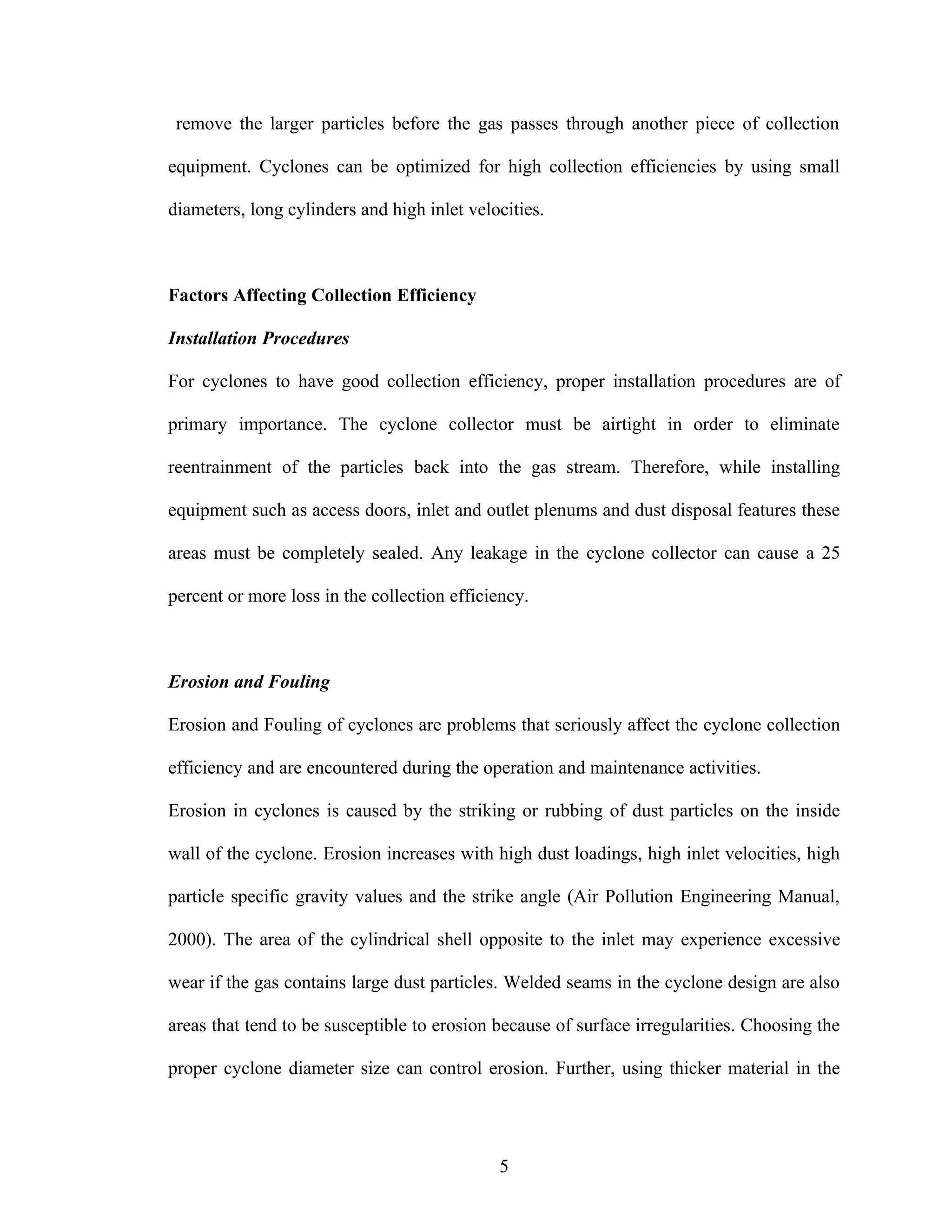

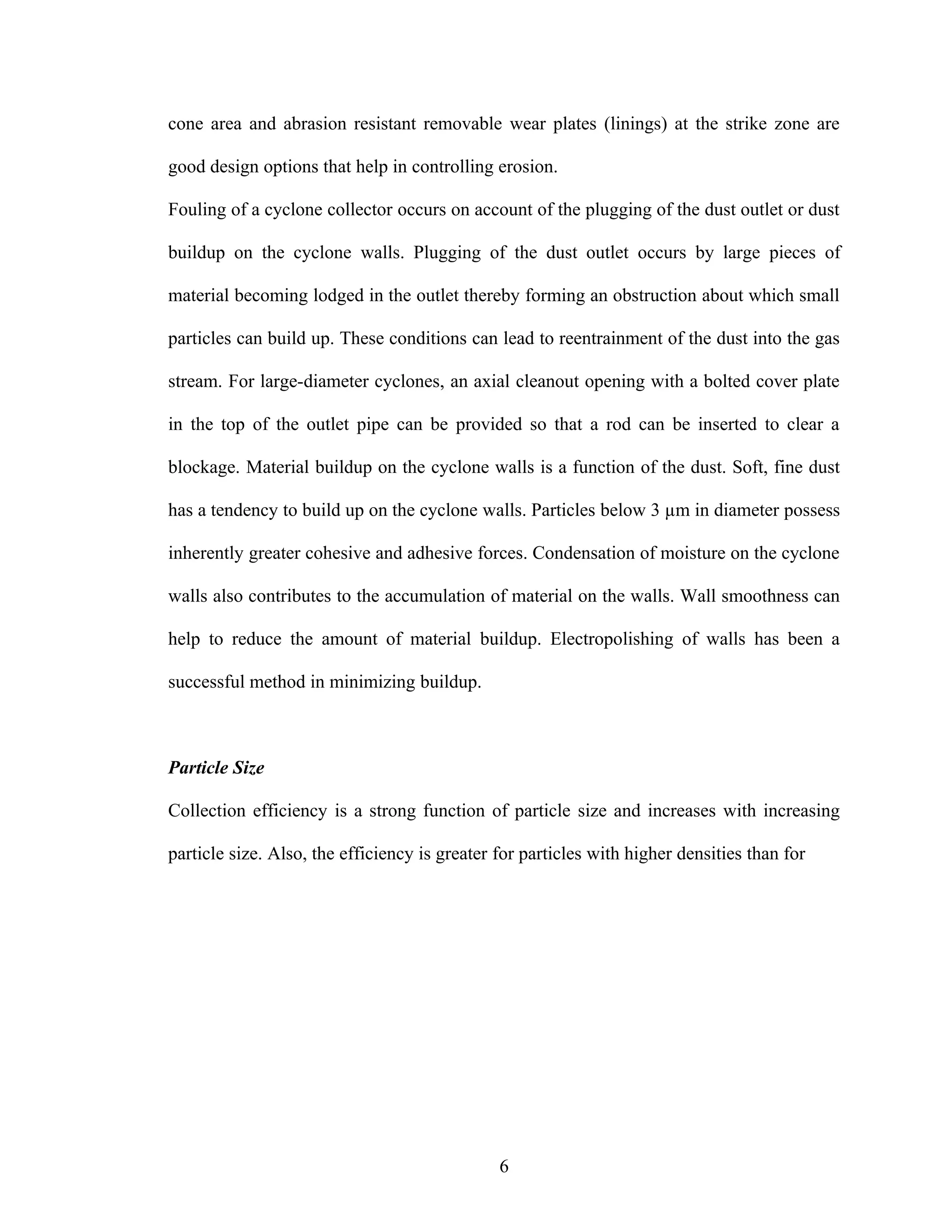

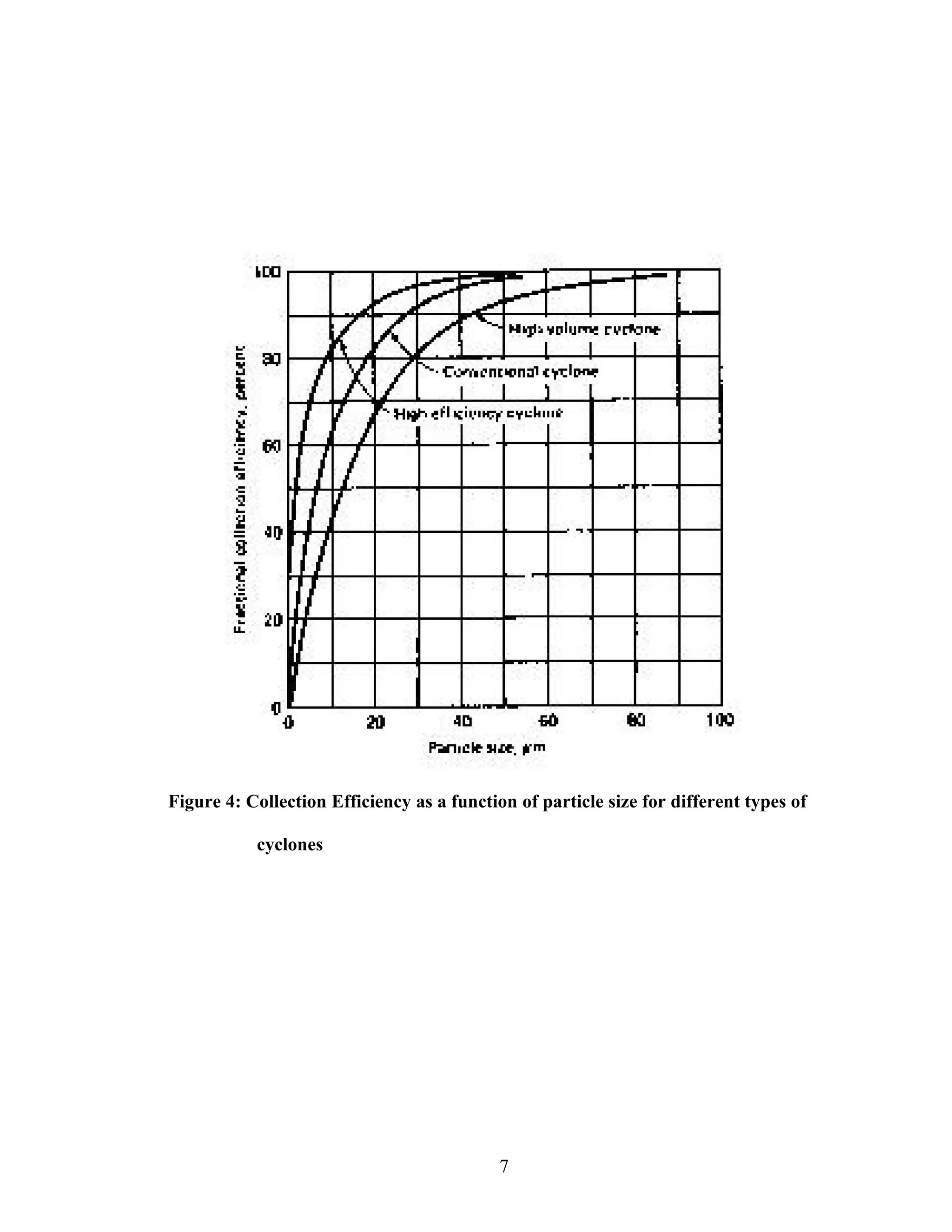

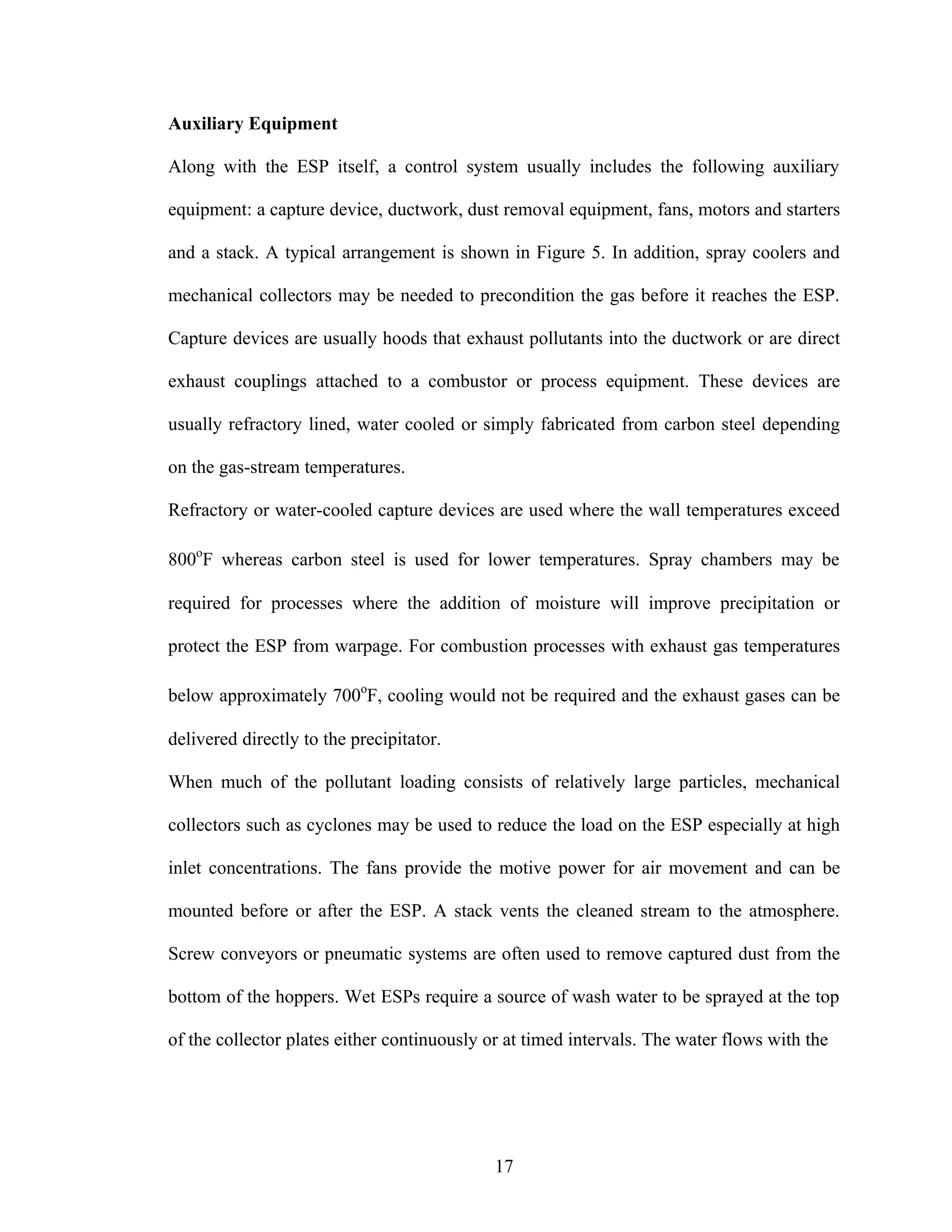

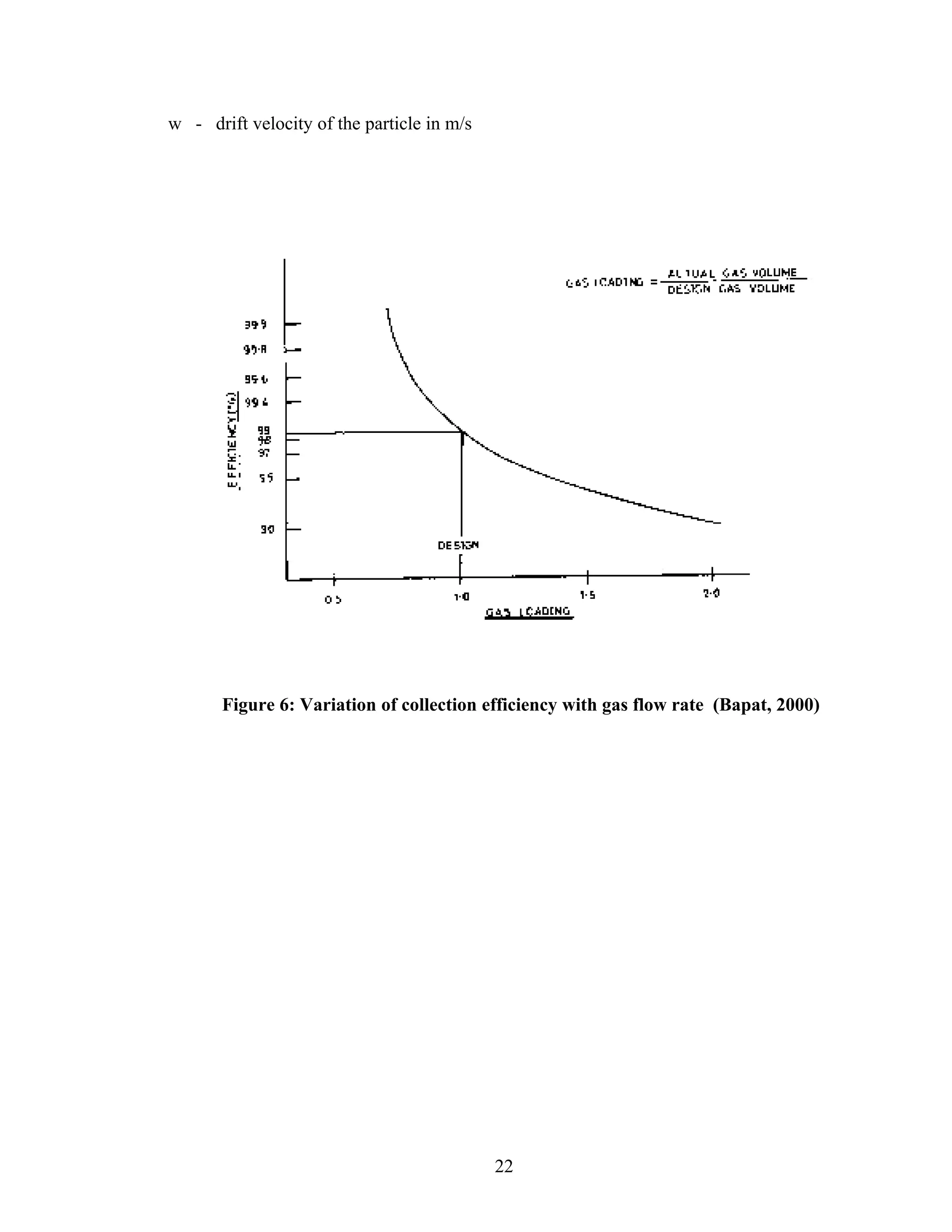

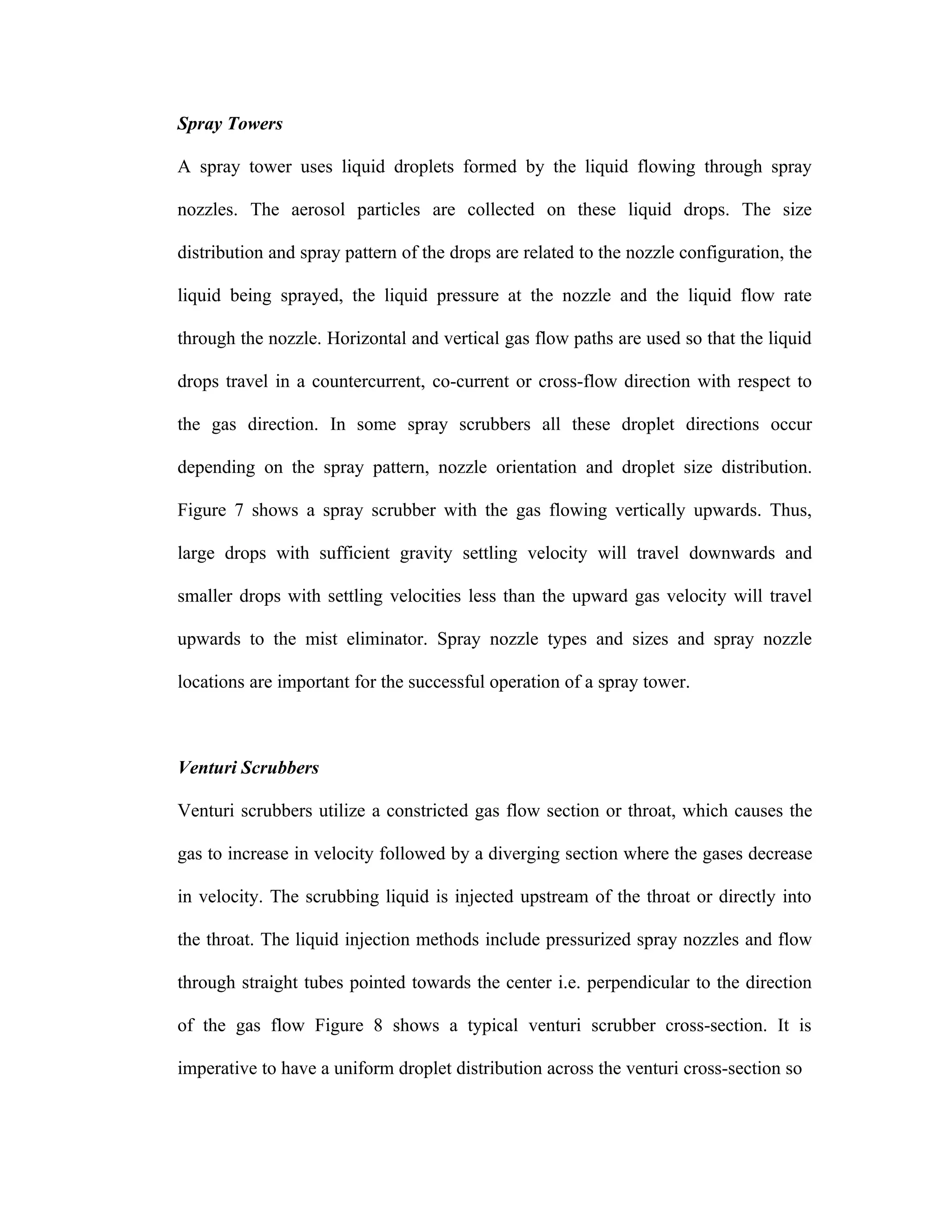

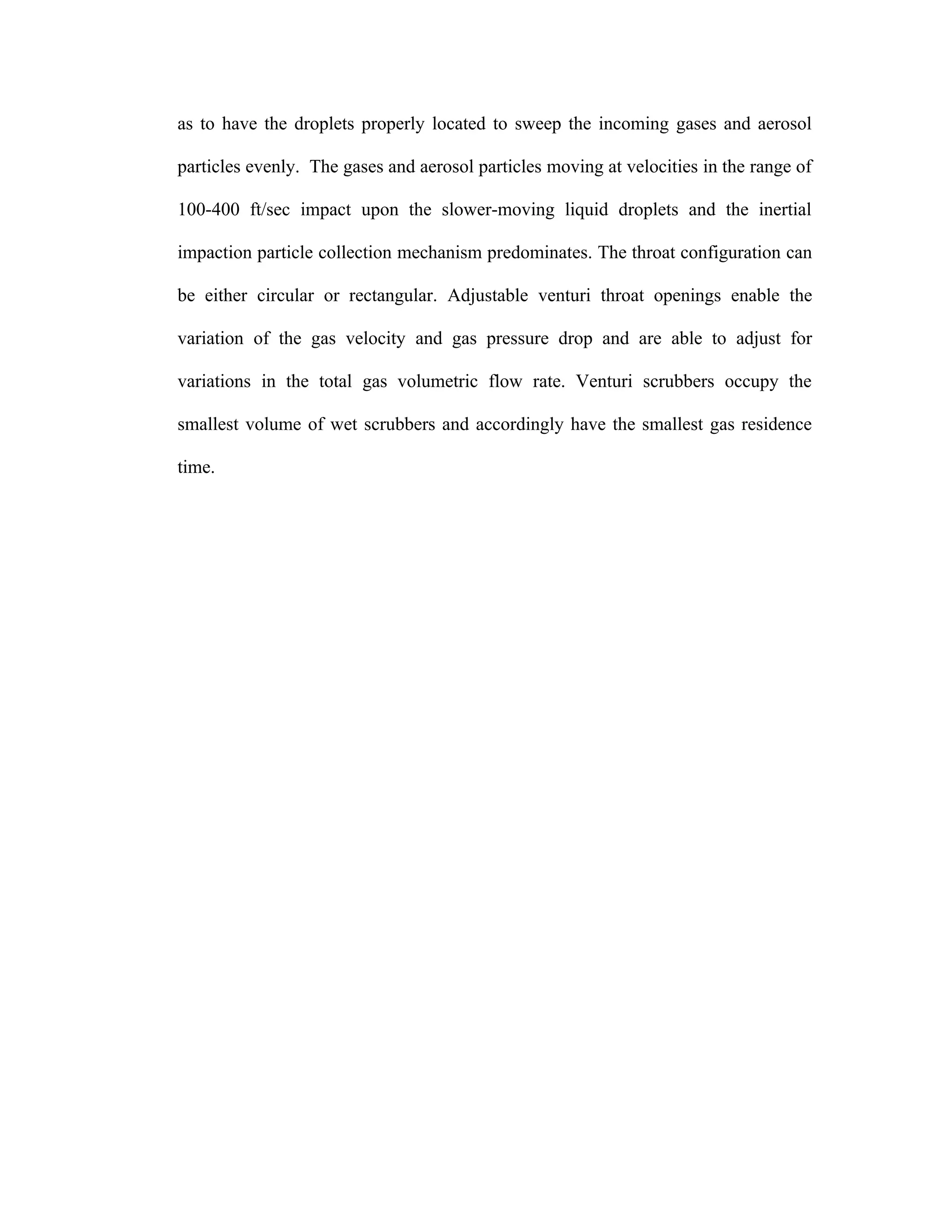

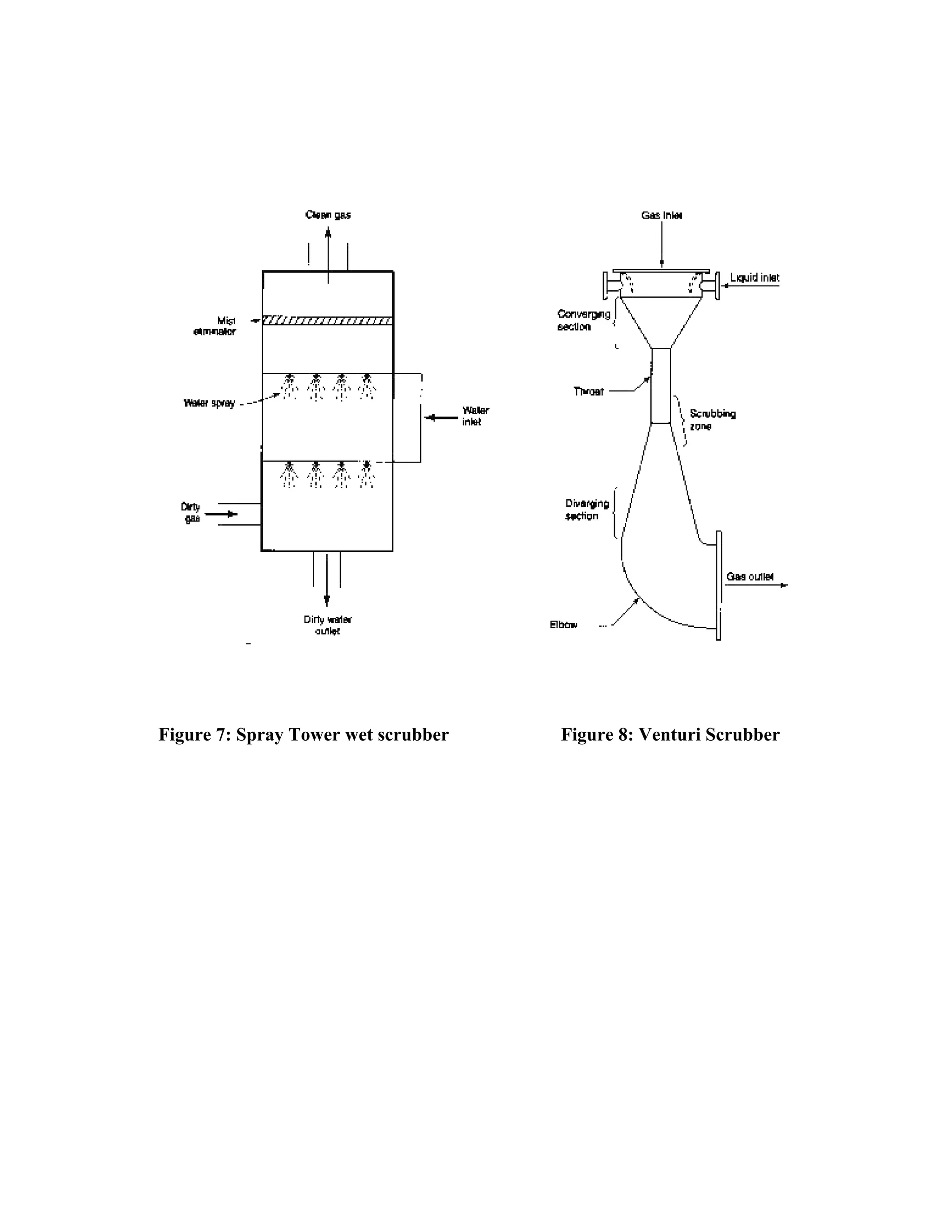

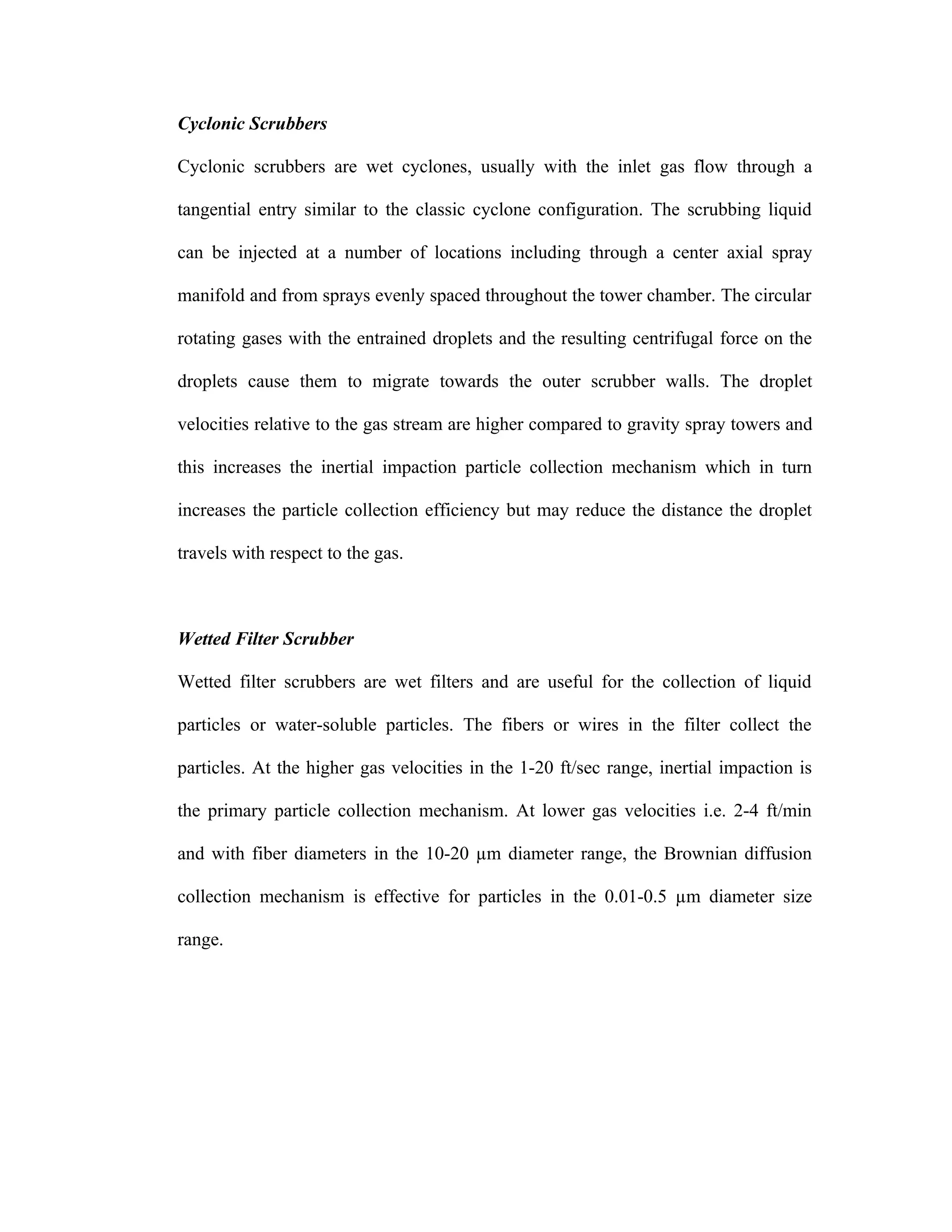

Inertial separators and cyclones are commonly used devices for particulate control that utilize centrifugal forces to separate particles from gas streams. Cyclones are the most common type of inertial separator and use cyclonic gas motion to fling particles to the outer walls, where they slide down and are collected. Factors like particle size, gas properties, installation quality, and design parameters affect the collection efficiency. Electrostatic precipitators also use electrical forces to remove particles, charging them and collecting on plates, and come in configurations like plate-wire and flat-plate designs suited for various applications.