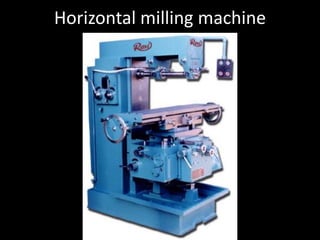

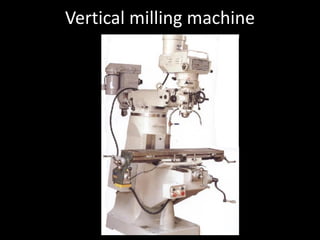

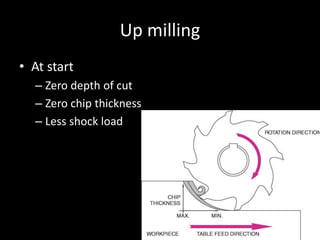

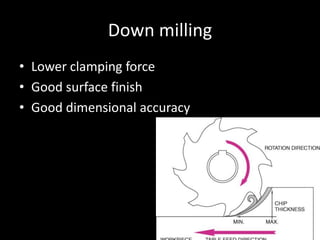

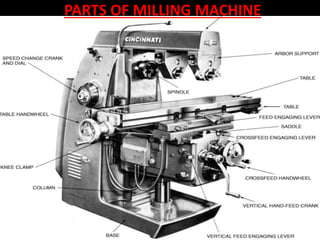

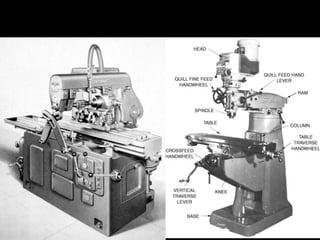

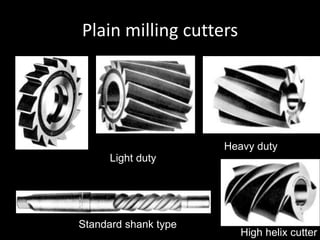

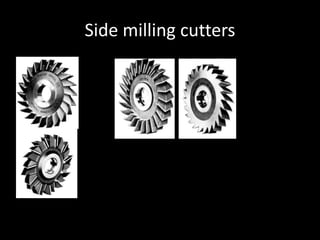

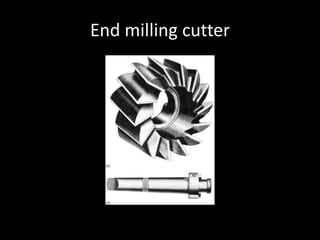

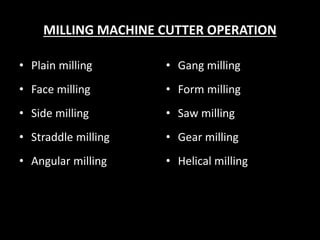

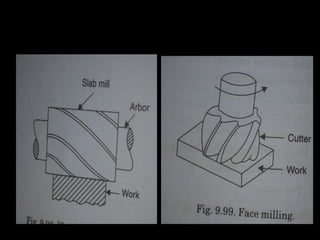

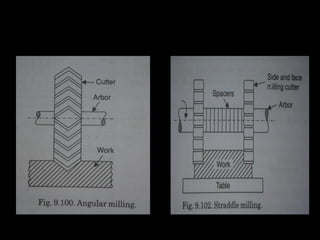

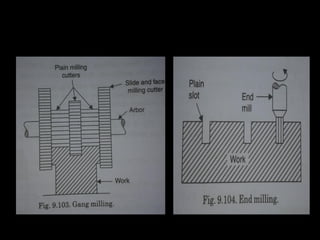

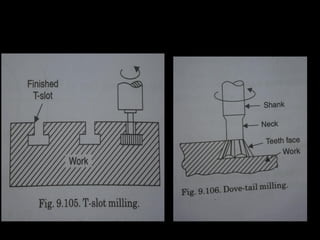

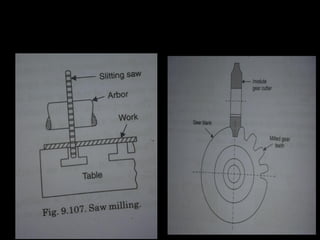

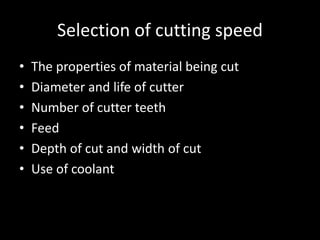

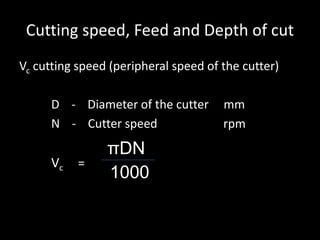

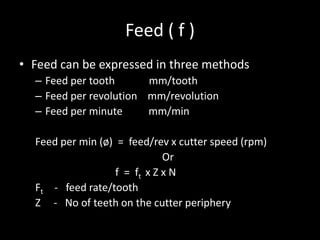

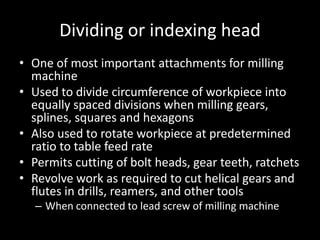

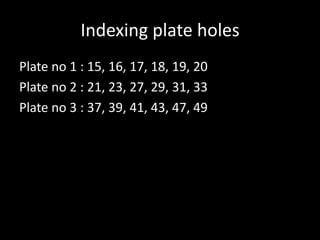

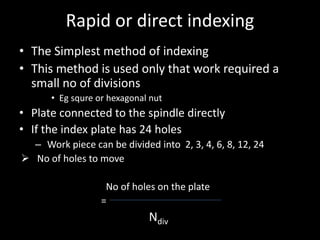

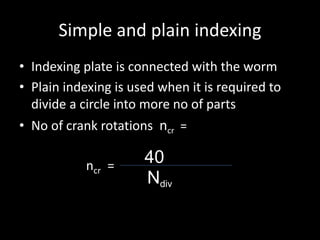

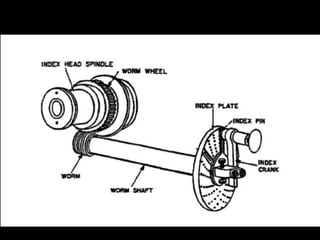

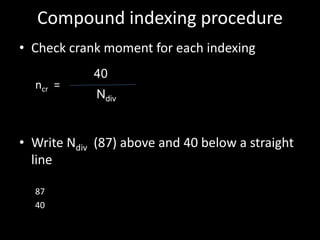

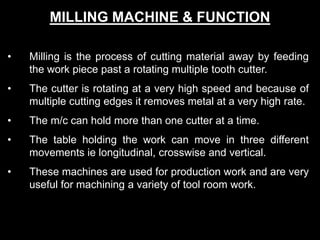

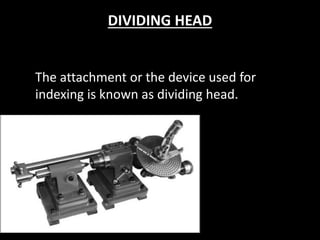

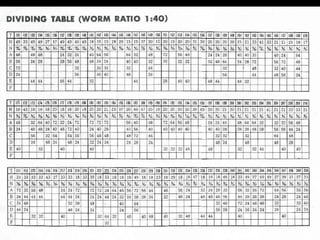

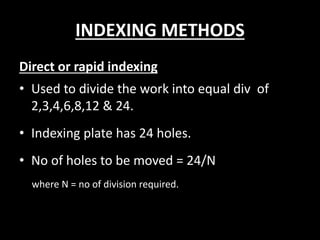

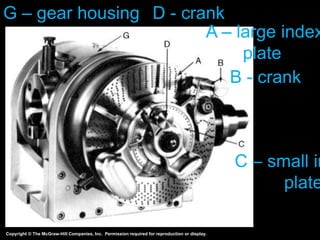

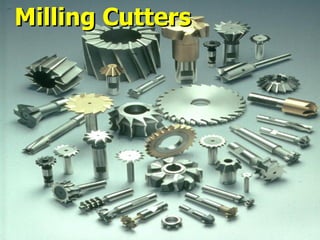

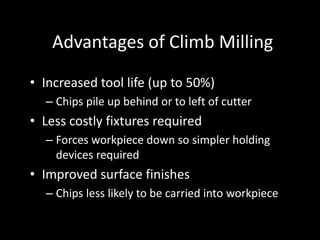

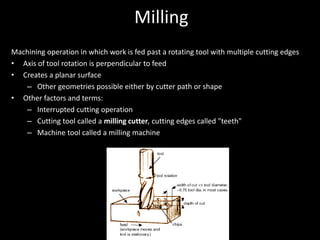

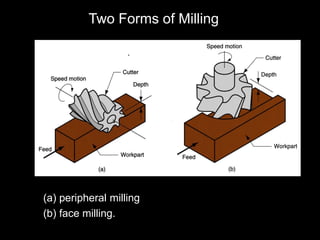

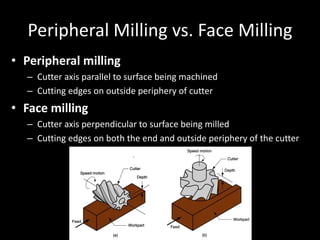

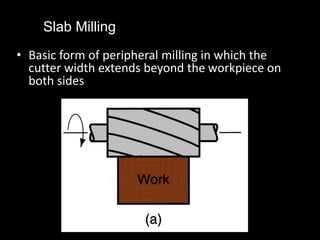

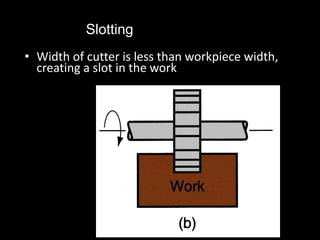

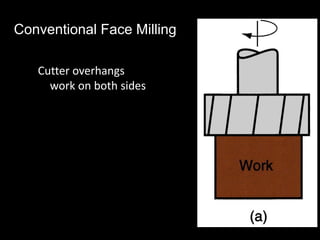

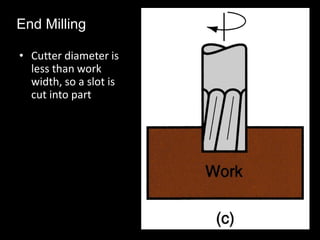

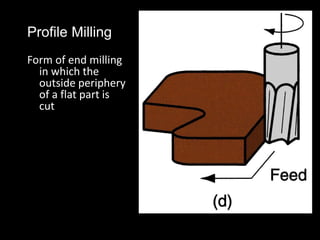

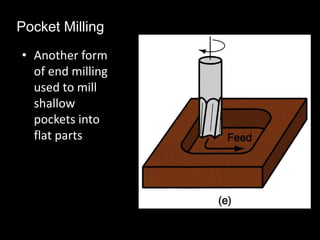

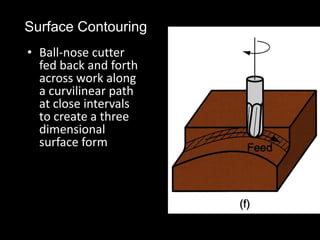

This document provides information about milling machines and milling operations. It defines milling as a machining process where material is removed from a workpiece using a revolving cutting tool. Various types of milling machines are described, including horizontal milling machines, vertical milling machines, and universal milling machines. Milling cutters, indexing, and other related topics are also summarized. The document aims to explain the basic concepts and components involved in milling processes.