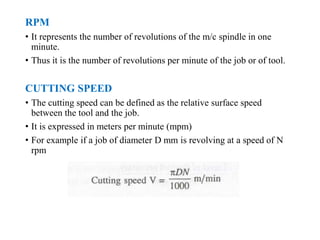

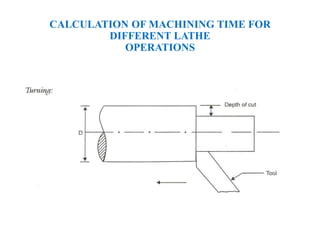

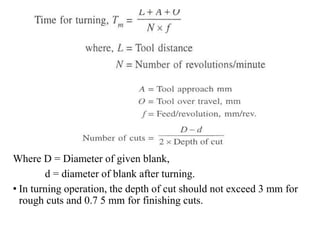

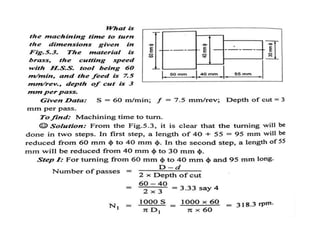

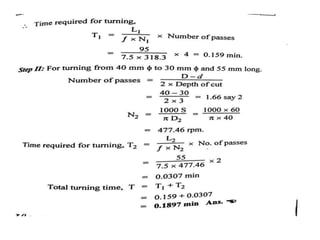

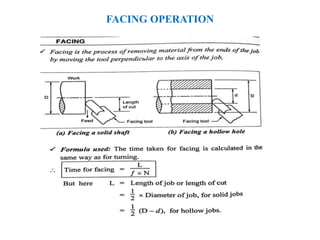

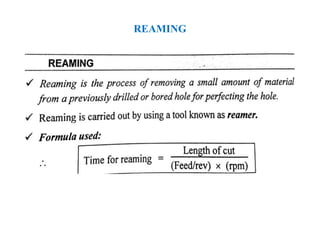

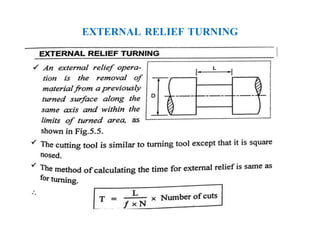

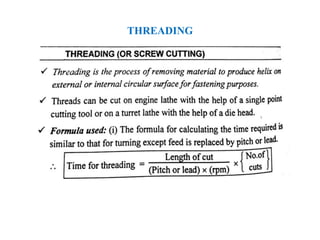

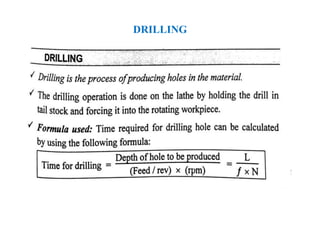

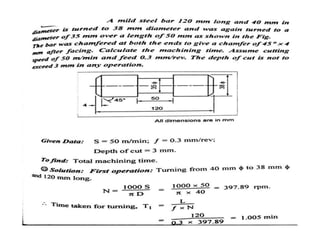

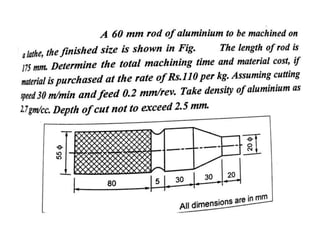

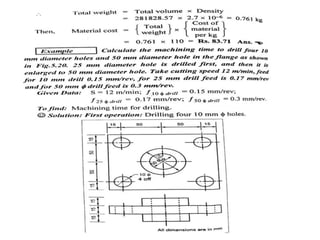

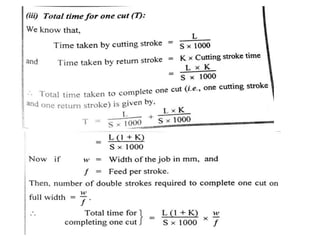

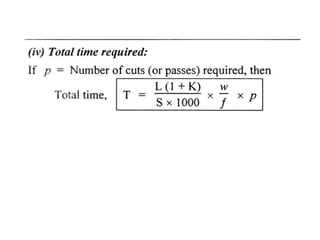

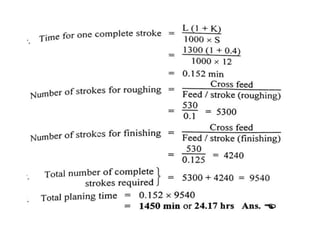

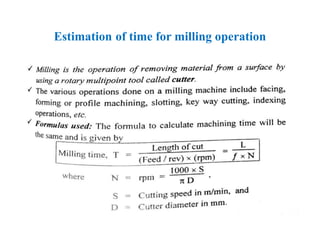

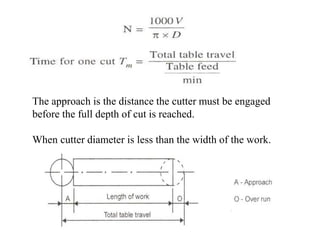

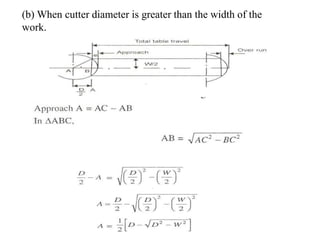

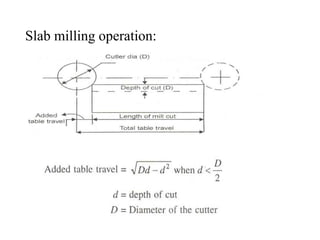

This document discusses the calculation of machining time for various operations. It provides formulas and factors to consider for estimating machining time for lathe operations like turning, facing, knurling, reaming, etc. It also discusses calculating time for milling, shaping, planning and grinding operations. Estimating machining time accurately is important for cost estimation since it allows calculating the machining costs based on time and rate. The document emphasizes that setup time, operation time, tear down time, and various allowances must be accounted for in machining time calculations.