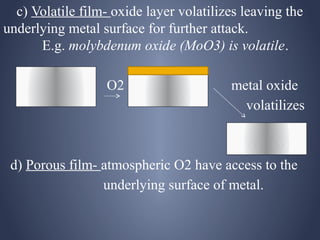

Corrosion is the deterioration of materials due to chemical or electrochemical reaction with the environment. It is an inevitable process that leads to significant economic losses. Corrosion engineering studies corrosion mechanisms and works to prevent or control corrosion economically and safely. Common types of corrosion include galvanic, erosion, crevice, pitting, and microbiologically influenced corrosion. Factors that influence corrosion include the metal properties, environmental conditions like temperature, pH, and presence of ions. Protection methods include material selection, cathodic protection, modifying the environment, metallic coatings, inorganic coatings, and organic coatings.

![3) The Acid Theory – applicable particularly to

rusting of iron

2Fe + O2 + 4CO2 + 2H2O 2Fe(HCO3)2

2Fe(HCO3)2 + H2O + [O] 2Fe(OH)CO3+2CO2+

2H2O

2Fe(OH)CO3 + 2H2O 2Fe(OH)3 + 2CO2](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-20-320.jpg)

![TYPES OF CORROSION

[I] Galvanic Corrosion (Bimetallic corroson):

E.g. Zinc and copper couple

More reactive Zn Zn2+ + 2e- At anode

(Corrodes)

Less reactive Cu2+ + 2e- Cu At Cathode

(protected)](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-21-320.jpg)

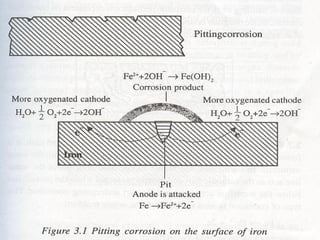

![[II] Erosion Corrosion:

Due to abrading action of flow of gases or

mechanical rubbing action of solids over the

metal surface.

[III] Crevice Corrosion:

Due to cracks in paint coating

[IV] Pitting Corrosion:

Most dangerous form of corrosion as it leads to

sudden failure of material due to formation of

holes.](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-25-320.jpg)

![[IV] Differential aeration Corrosion (Oxygen

Concentration Cell Corrosion)

• One part of the metal is exposed to a different

air/O2 concentration from the rest of the part.

• Portion with lesser O2 = Anode

• Portion with more O2 = Cathode

• e.g. A iron nail inside the wood undergoes

corrosion easily](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-29-320.jpg)

![[V] Waterline Corrosion](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-30-320.jpg)

![[VI] Micro-Biological Corrosion :

Due to metabolic activity of various micro-

organisms

[VII] Stress-Corrosion Cracking

•Metal under stress becomes more anodic and

tend to increase the rate of corrosion.

•The stress can be due to non-uniform

deformation by unequal cooling from high

temperature as in welding](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-31-320.jpg)

![PROTECTION FROM CORROSION

[I] Design and Material Selection](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-36-320.jpg)

![[II] Cathodic Protection

(i) By appropriate galvanic coupling:](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-40-320.jpg)

![[III] Modifying the Environment

i) Deaeration

ii) Deactivation : addition of chemicals, capable of

combining rapidly with O2 in aqueous solution

iii) Dehumidification: by using alumina or silica gel

iv) Alkaline neutralization

v) Use of inhibitors

a. By forming a layer in between which acts as a

barrier between the material and environment.

b. Or by retarding the anodic or cathodic or both

processes](https://image.slidesharecdn.com/corrosion-130413030451-phpapp02/85/Corrosion-43-320.jpg)