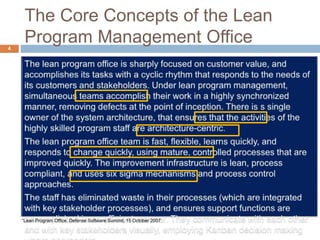

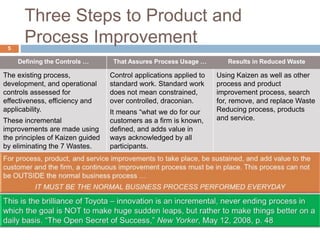

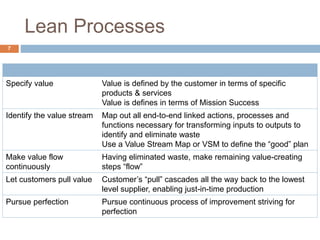

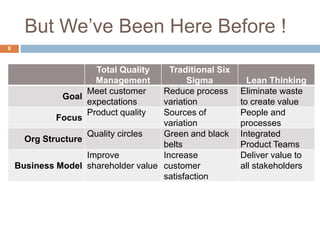

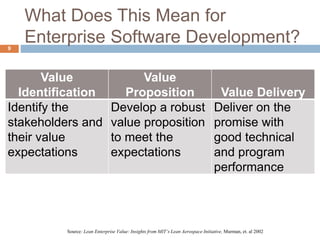

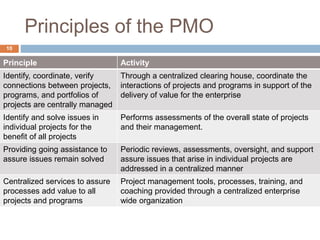

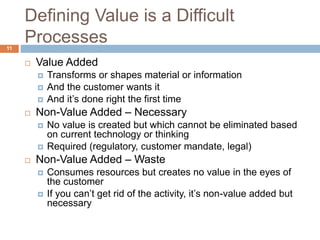

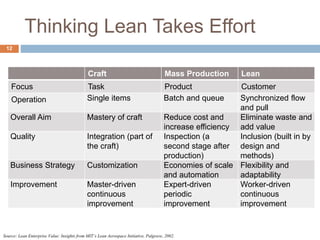

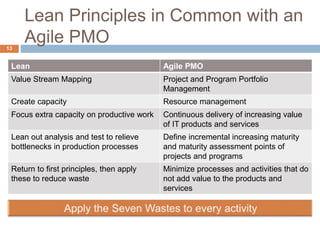

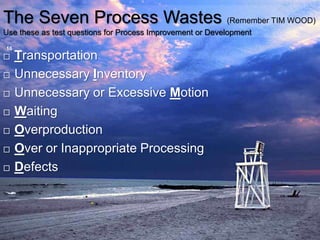

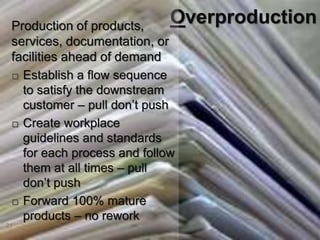

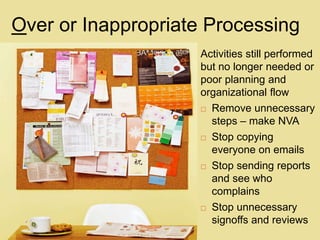

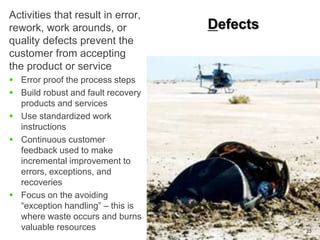

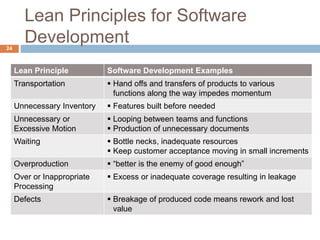

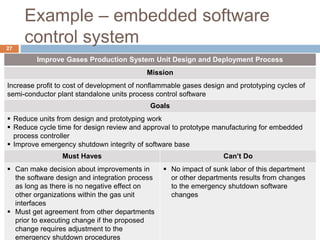

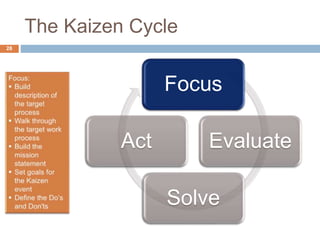

The document discusses the integration of program management offices (PMOs) with agile and lean methodologies to enhance business improvement. It outlines lean principles such as value stream mapping and waste reduction, emphasizing the importance of continuous improvement in software development. Key concepts include defining value from the customer's perspective and coordinating project management efforts to ensure efficient delivery of value to stakeholders.