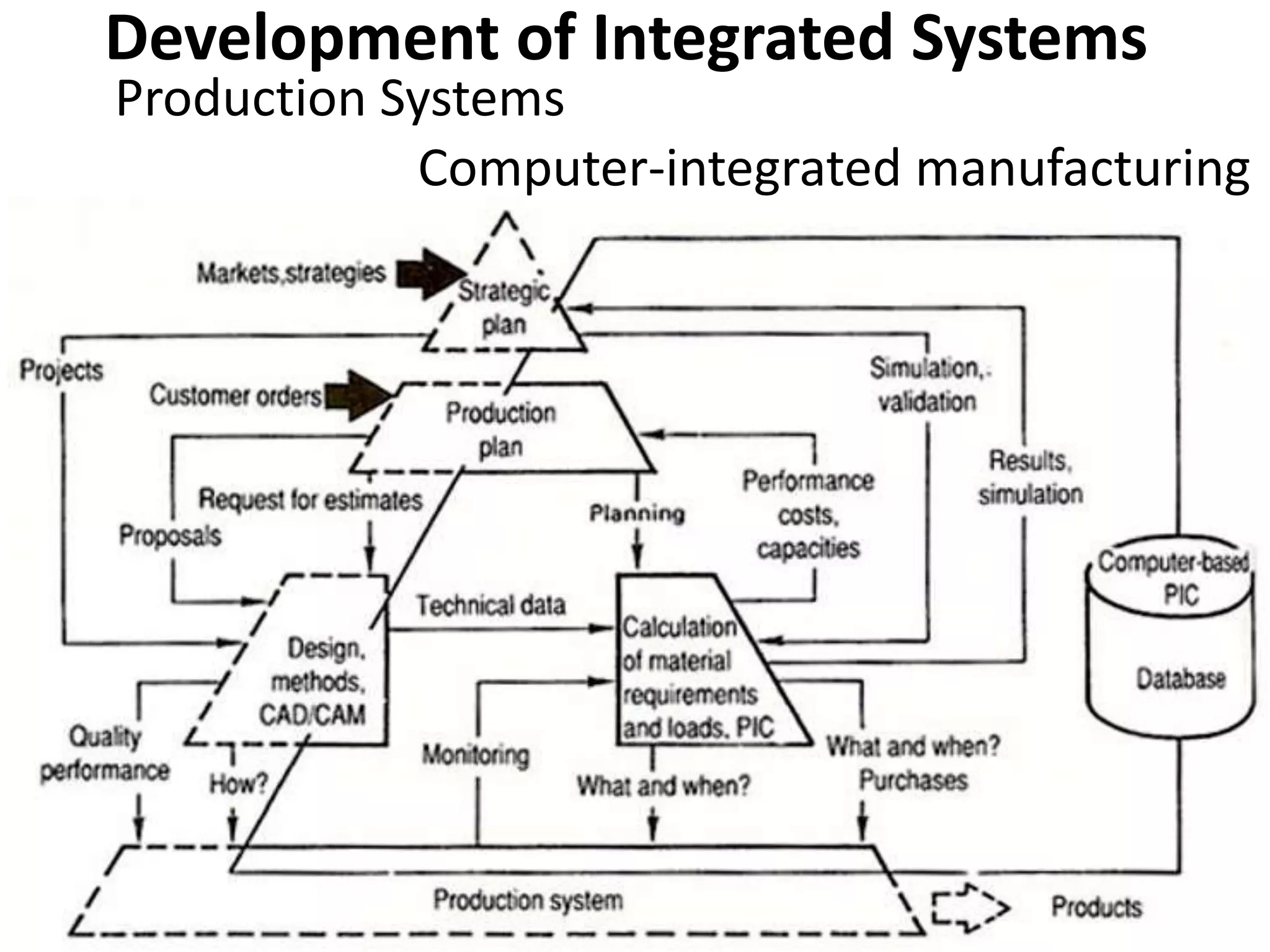

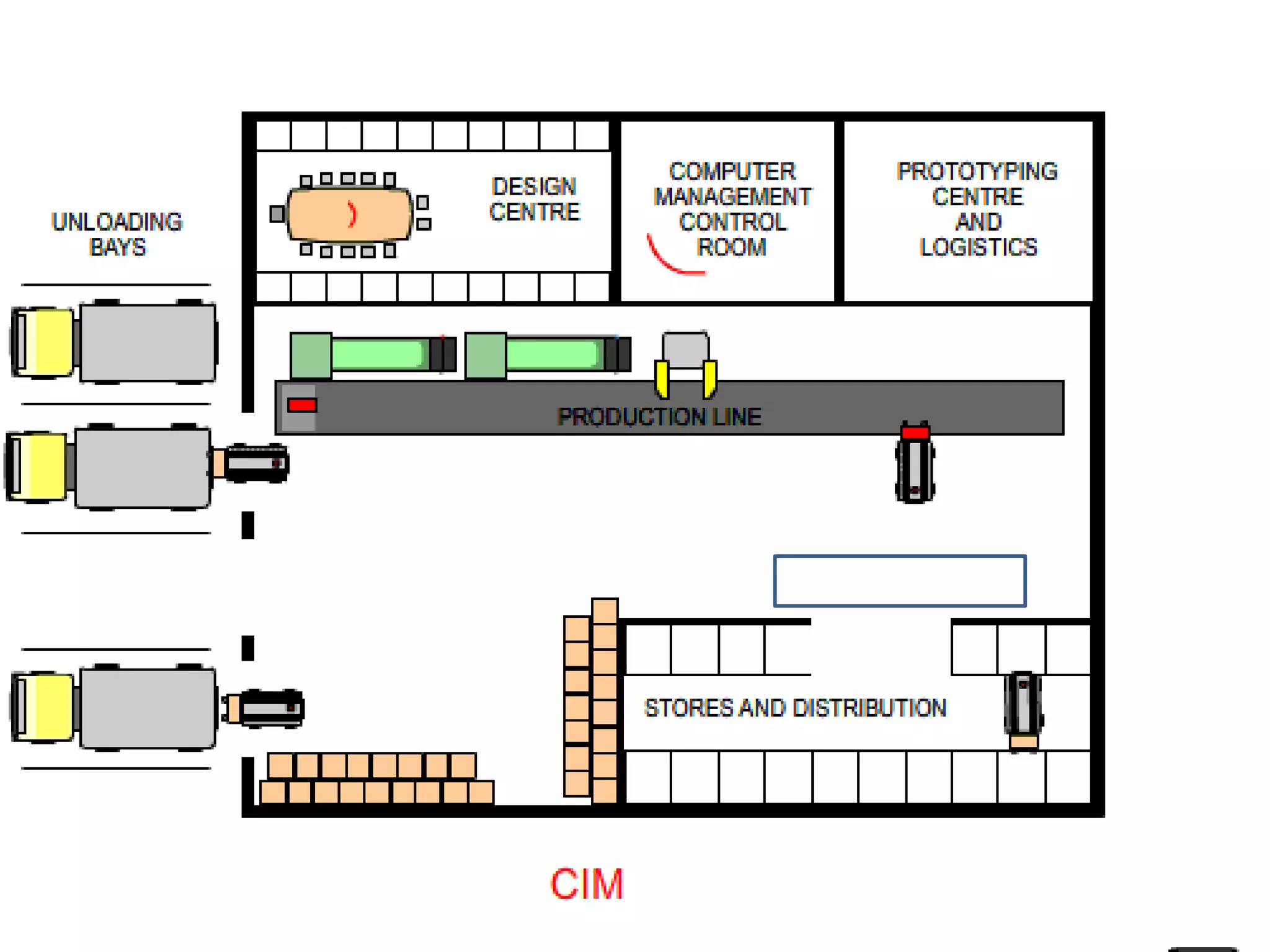

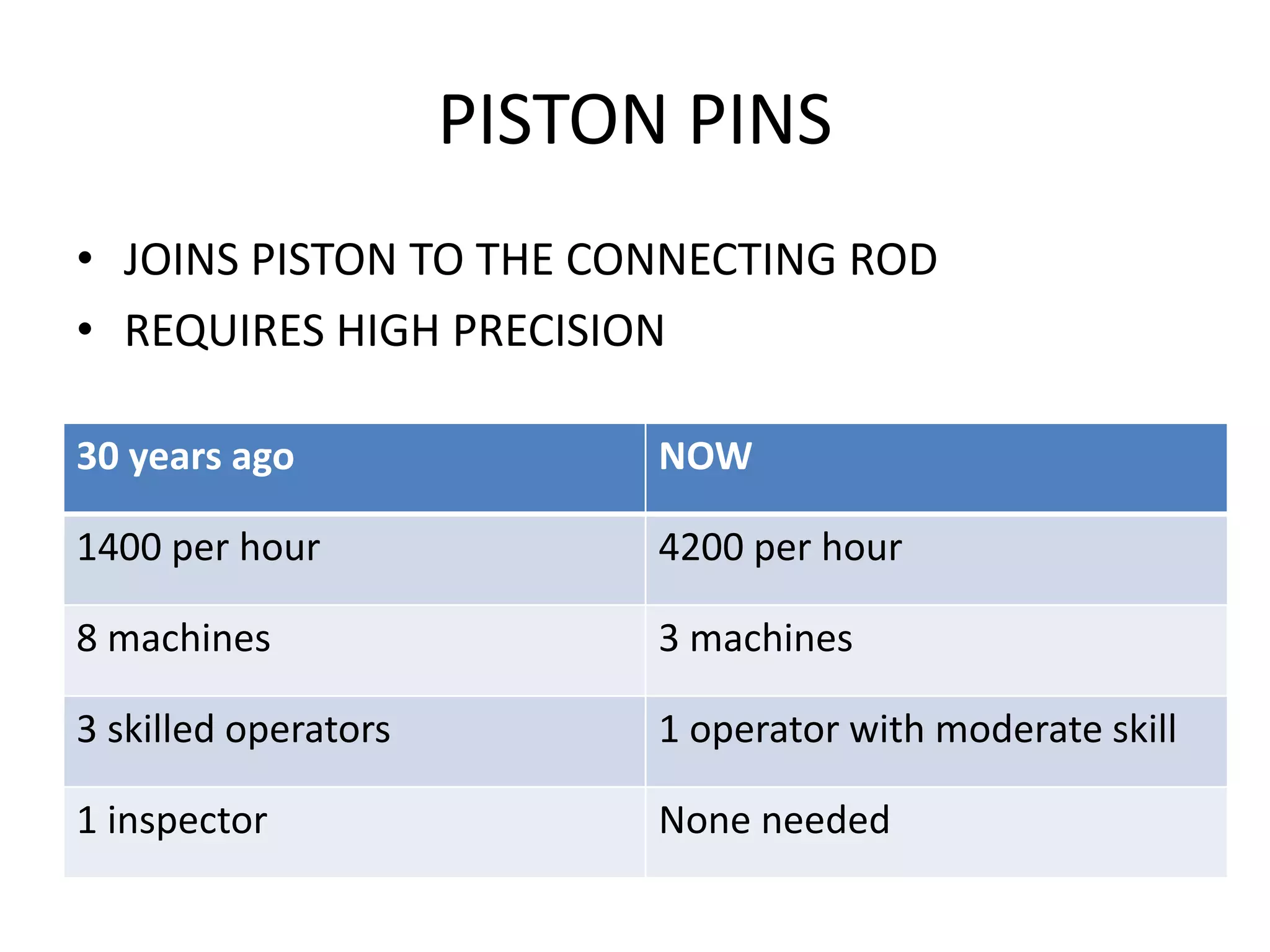

The document discusses the use of computers in industrial engineering. It describes how computers can be used for tasks like material requirements planning, manufacturing resource planning, just-in-time manufacturing, computer-aided design, computer-aided manufacturing, robotics, and flexible manufacturing systems. It also discusses the development of integrated systems that combine CAD/CAM, computer-aided process planning, and computer-integrated manufacturing. The document provides an example of how automation and computerization at a piston pin factory increased production from 1400 pins per hour to 4200 pins per hour using fewer machines and less skilled workers.