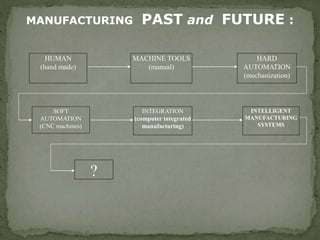

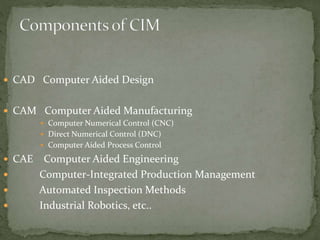

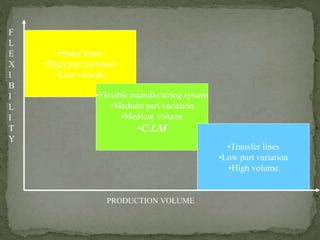

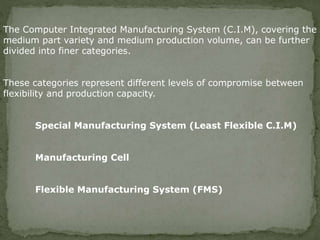

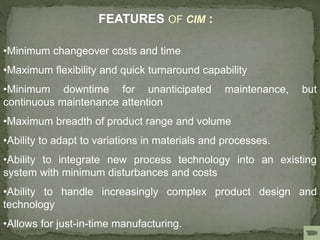

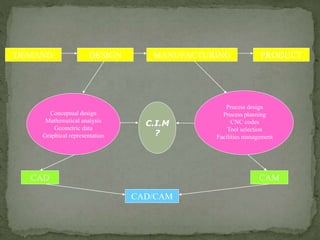

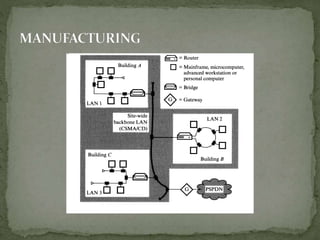

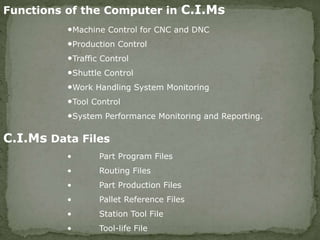

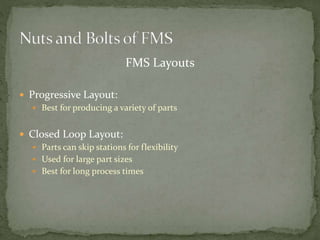

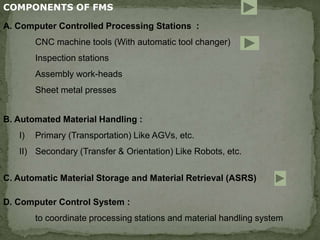

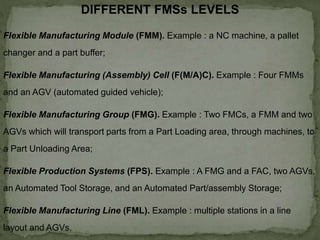

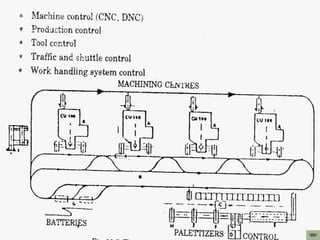

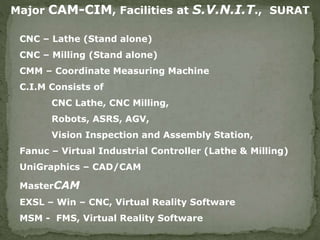

Computer integrated manufacturing (CIM) is the integration of all enterprise operations and activities around a common corporate data repository through the use of integrated systems and data communications coupled with new managerial philosophies. CIM is not a product that can be purchased and installed, but rather a way of thinking and solving problems through the use of computers for on-line automation, optimization, and integration of the total manufacturing system from design to production. Flexible manufacturing systems (FMS) bridge the gap between high-production transfer lines and programmable but low-production numerical control machines by allowing for medium part variety and medium production volumes. FMS consist of computer-controlled machines connected by an automated material handling system.