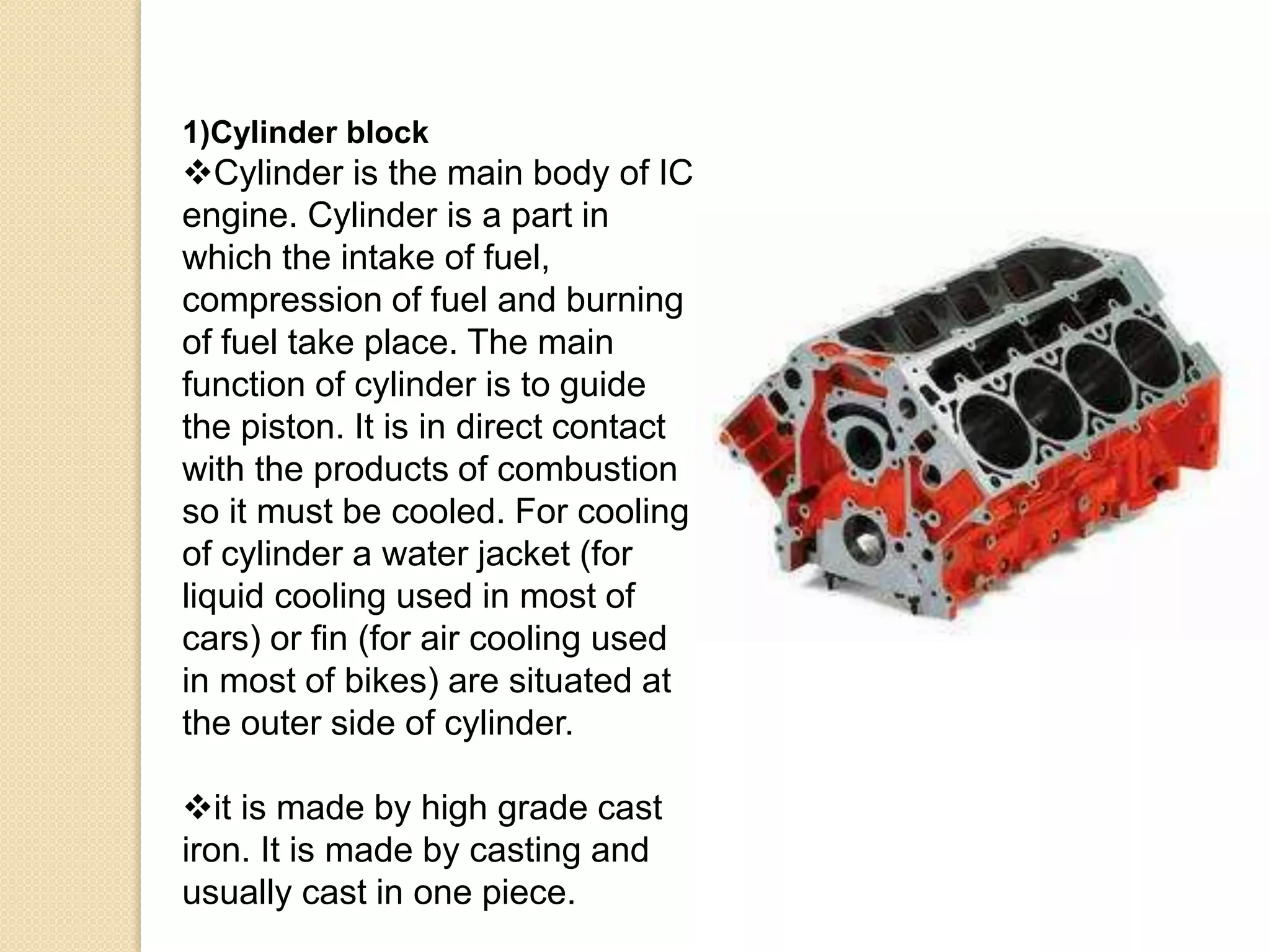

This presentation discusses internal combustion engines. It provides an introduction and overview of external combustion engines and internal combustion engines. It then focuses on internal combustion engines, describing their main parts like the cylinder block, cylinder head, piston, connecting rod, crankshaft, valves, spark plug, injector, manifold, and camshaft. It also defines important engine terminology and classifications of internal combustion engines. The advantages of internal combustion engines are listed as having higher efficiency than external combustion engines while also being more compact and having a lower initial cost.