This document summarizes a keynote paper presented at the 10th International Congress on Fluid Dynamics regarding numerical simulation approaches for optimizing the design of micro combustion chambers. It discusses the design process for tubular and annular combustion chambers, focusing on mixing processes, aerodynamic design considerations, and airflow distribution within the combustion liner. Design equations are provided for determining the casing area, liner area, liner length, and airflow based on parameters like mass flow rate, temperature, and pressure. Design data from previous studies is also presented to enable the modeling and simulation of sample tubular combustion chambers.

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 2

Copyright © 2010 by ICFD 10

parasitic losses and with minimal length and pressure loss. Successful aerodynamic design

demands knowledge of flow recirculation, jet penetration and mixing, and discharge coefficients

for all types of air admission holes, including cooling slots.

Good amount of literature is available on modeling of the process of combustion for kerosene

and hydrocarbon fuels (Wooley et al. [1], Phillipe et al. [2], Z. Wen et al. [3], E. Reismeier et al.

[4], Sierra et al. [5] B. Zamuner [6], Grinstein et al. [7], Caraeni et al. [8], Gran et al. [9], Shyy et

al. [10, 11], Cooke et al. [12]). Charles K. Westbrook et al. [13] have reviewed the progress in

the field of computational combustion over last 50 years encompassing 3D DNS and LES

approaches. They have observed that many commercial CFD codes uses unstructured grid which

offer the advantage of being more suitable to massively parallel computing environment, as well

as an ability to deal with complex geometries.

The paper presents the design of tubular and annular combustion chamber followed by three

dimensional simulations in tubular and annular combustor with full film cooling to investigate

the velocity profiles, species concentration and temperature distribution within the liner. The fuel

under consideration is hydrogen and primary zone equivalence ratio variation from 0.5 to 1.6

were simulated. Reactive flow calculations were carried out with 19 reversible reactions and nine

species. The computational approach attempts to strike a reasonable balance to handle the

competing aspects of the complicated physical and chemical interactions of the flow and the

requirements in resolving the three-dimensional geometrical constraints of the combustor

contours, cooling slots, and circular dilution holes. The modeling employs non-orthogonal

curvilinear coordinates, second-order accurate discretisation, multi-grid iterative solution

procedure, the SST k -ω turbulence model, and a combustion model comprising of an assumed

probability density function flamelet concept. The complicated mixing process can be better

understood with more detailed information supplied by the numerical simulation. Accordingly,

in present study an attempt has been made through CFD approach using CFX 12 to analyze the

flow patterns within the combustion liner and through different air admission holes, namely,

primary zone, intermediate zone, dilution zone and wall cooling, and from these the temperature

distribution in the liner and at walls as well as the temperature quality at the exit of the](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-2-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 3

Copyright © 2010 by ICFD 10

combustion chamber is obtained for tubular and annular combustion chambers designed for gas

turbine engine.

DESIGN OF COMBUSTION CHAMBER

Basic Terminology

Figure 1 Typical Combustor Cross Section [14].

There is a need to discuss the basic combustor chamber terminology to understand the different

components of combustion chamber. Figure 1 is a cross-section of a generic diffusion flame

combustion chamber. The main dimensions of the combustion chamber are the casing and liner

area. The other dimensions are dependent of these areas and accordingly the design methodology

is given in the following section.

Casing Area

(A) Aerodynamic Consideration

For straight-through combustors the optimal cross-sectional area of the casing refA is determined

from considerations of overall pressure loss and combustion loading. However, for most

industrial combustors and some aircraft combustors, the casing area needed to meet the

combustion requirements is so low as to give an unacceptably high pressure loss. Under these

conditions the overall pressure loss dictates the casing size and refA is obtained as [14]:](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-3-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 4

Copyright © 2010 by ICFD 10

( )

0.52

1

0.5

3 3 3 4 3 4

3 3

1

2

ref

ref

m T P PR

A

P q P

−

− −

⎡ ⎤⎛ ⎞

⎛ ⎞Δ Δ⎢ ⎥⎜ ⎟= ⎜ ⎟⎢ ⎥⎜ ⎟ ⎝ ⎠⎢ ⎥⎝ ⎠⎣ ⎦

(B) Chemical Consideration

This method is used to size the chamber with the chemical considerations in mind. It attempts to

ensure a high value for the combustion efficiency. This efficiency is represented by θ parameter,

which is given by [14]:

( )

1.75 0.75 3

3 exp

2

ref ref

A

T

P A D

b

m

θ

⎛ ⎞⎛ ⎞

⎜ ⎟⎜ ⎟⎝ ⎠=⎜ ⎟

⎜ ⎟⎜ ⎟

⎝ ⎠

Liner Area

At first sight it might appear advantageous to make the liner cross-sectional area as large as

possible, since these results in lower velocities and longer residence times within the liner, both

of which are highly beneficial to ignition, stability, and combustion efficiency. Unfortunately, for

any given casing area, an increase in liner diameter can be obtained only at the expense of a

reduction in annulus area. This raises the annulus velocity and lowers the annulus static pressure,

thereby reducing the static pressure drop across the liner holes. This is undesirable, since a high

static pressure drop is needed to ensure that the air jets entering the liner have adequate

penetration and sufficient turbulence intensity to promote rapid mixing with the combustion

products. These considerations suggest that a satisfactory criterion for mixing performance

would be the ratio of the static pressure drop across the liner LPΔ to the dynamic pressure of the

flow in the combustion zone pzq . If the ratio of liner cross-sectional area to casing cross-

sectional area is denoted by k , then the optimal value of k is that which gives the highest value

of L pzP qΔ . It can be shown [14] that:

( ) ( )

( )

( )

2 22

2

3 3 4

22

1 1 1

1 3

1

sn

L

pz pz p ref

m r kT PP k

q T m q k

λ

−

⎧ ⎫⎡ ⎤− + − −ΔΔ ⎪ ⎪⎣ ⎦= + −⎨ ⎬

−⎪ ⎪⎩ ⎭](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-4-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 5

Copyright © 2010 by ICFD 10

Airflow Distribution within Liner

An important aspect of combustor design is to determine the number, size, shape and disposition

of the liner holes to establish airflow pattern within the liner that will ensure easy light-up,

efficient and stable combustion, adequate wall cooling and delivery of gases to the turbine with a

suitable temperature profile. If the liner wall contains a row of n holes, each of which has an

effective diameter jd , then the total mass flow rate jm of air through these holes is given by:

( )2

0.5

3

3

15.25

4j

j

L

m

nd

P

P

T

=

Δ⎛ ⎞

⎜ ⎟

⎝ ⎠

Length of Liner

The length of liner is given by:

( )

1

1

ln 5

1

L

L L

ref

P

L D A

q PF

−

⎛ ⎞⎛ ⎞Δ

= ⎜ ⎟⎜ ⎟⎜ ⎟−⎝ ⎠⎝ ⎠

DESIGN DATA

Saravanamutto et al. [15] has given cycle analysis and performance characteristics of individual

components of gas turbine engine while Desai N. M [16] and Pandya M. P. [17] has carried out

extensive work on laboratory scale gas turbine engine. The data for designing tubular type

combustion chamber is extracted from the work of these researchers by performing the cycle

analysis and presented in Table 1.

Table 1 Design Data for Combustion Chamber [16, 17].

No Parameter Value

1 Inlet Pressure to Combustion Chamber 2.89 bar

2 Inlet Temperature to Combustion Chamber 870.266K

3 Mass Flow Rate of Air 0.10279 kg/s

4 Exit Temperature of Combustion Chamber 1200 K

5 Mass Flow Rate of Fuel (Hydrogen) 0.0008 kg/s

6 Designed Air Fuel Ratio (Hydrogen) 128.5](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-5-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 6

Copyright © 2010 by ICFD 10

The design of the combustion chamber is carried out as outline in the literature [18, 19, 20] and

design procedure given in previous section. Table 2 gives the dimensional details of Hydrogen

fuelled tubular type micro gas turbine combustion chamber while figure 2 shows the dimensional

drawing of the combustion chamber.

Table 2 Dimensional Details of the Combustion Chamber [18, 19, 20].

Chamber

Casing

Area

(m2

)

Liner

Area

(m2

)

Air admission holes

Primary

Zone

Dilution

Zone

Wall Cooling

Primary Zone Dilution Zone

n

dh

(mm)

n

dh

(mm)

n

dh

(mm)

N

dh

(mm)

Tubular 0.0019 0.0014 6 5.98 3 13.07 78 1.83 100 1.32

Figure 2 Detailed Dimensional Drawing of Micro Combustion Chamber.

Figure 3 shows the annular combustion chamber for hydrogen fuel designed as a part of

development of Micro Gas Turbine Engine under development jointly at S. V. National Institute

of Technology, Surat and C. K. Pithawalla College of Engineering and Technology, Surat. The

design of annular combustion chamber is carried out as per the design procedure for tubular](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-6-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 8

Copyright © 2010 by ICFD 10

Basic Assumptions and Boundary Condition

• The combustion chamber is analyzed by a single entry at diffuser

• The flow is allowed to divide by itself into liner and casing, and from casing into different

zones through air admission holes and cooling slots.

• Such condition is the exact replica of the real case experimentation, in which the air is

supplied at the inlet diffuser with known conditions of pressure, temperature and velocity,

and then, allowed to divide between the casing and the liner.

• Majority of the researchers working in the area of computational combustion have selected k

– ε model to capture physics of turbulence [21, 22]. The k – ε model under predicts

separation and is highly inaccurate with swirling flows and flows with strong streamline

curvature. In comparison to k – ε, SST k – ω accounts for the transport of the turbulent shear

stress and gives highly accurate predictions of the onset and the amount of flow separation.

Also, the model can be used with coarser near-wall mesh and produce valid results.

• A large variety of kinetic schemes and mechanisms varying from very complex schemes to

single step fast chemistry is available for hydrocarbon combustion [23, 24]. Few researchers

have observed that reduced kinetic and single step chemistry offers reasonable predictions

with limited computational power [25, 26]. But single step chemistry over predicts the

temperature levels along the combustor and hence gas-phase reaction model for the

combustion of hydrogen and air mixture consists of 19 reversible elementary reactions and

nine species was selected.

• Wall boundary condition and heat loss does influence the flame structure and predictions of

temperature levels in combustion system [27, 28]. In present case, for the 3D calculations

with CFX, the adiabatic system model is used because of large mass flow rate of air through

annulus which keeps wall cooled casing nearly at ambient temperature.

GRID INDEPENDENCY

The three-dimensional grid independent study was carried out with number of nodes varying

from 145000 to 234000 nodes. The simulation results do not vary comprehensively between

nodes of 176000 to 234000 and hence a grid with 195000 nodes was selected for CFD

simulations. The grid spacing selected is similar to the Eulerian grid and is finest at the nozzle](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-8-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 9

Copyright © 2010 by ICFD 10

exit and becomes gradually coarser away from the nozzle. Due to unstructured grid high

resolution advection scheme is selected for additional accuracy.

CFD MODELING OF HYDROGEN FUEL

The mixing process occurs within the combustion chamber which is also part of the simulated

region and so a non-premixed model was used. The gas-phase reaction model for the combustion

of hydrogen and air mixture consists of 19 reversible elementary reactions and nine species.

Third body efficiencies for all intermolecular reactions are 2.5 for H2, 16 for H2O, and 1.0 for all

the rest of species, as reported in Tien and Stalker [29]. The combustor modeling is carried out

using eddy dissipation model based on the concept that chemical reaction is fast relative to the

transport processes in the flow. When reactants mix at the molecular level, they instantaneously

form products. The CFD Models are summarized in table 4.

Table 4 CFD Models.

Fluid Model Thermal Energy

Turbulence Model SST k – ω

Combustion Model Eddy Dissipation

Radiation Model Discrete Transfer

Nitrogen Constraint

Combustion Reaction Hydrogen Air Multi step

CFX-RIF Generator was used to include 19 reversible reactions and 9 species for ANSYS CFX.

The solution convergence is judged according to the residuals of governing equations. The

results reported in this paper are based on the criteria that the residual of each equation should be

smaller than 1.0×10−6

. Each simulation normally takes about 900 CPU hours.](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-9-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 12

Copyright © 2010 by ICFD 10

The uncertainty analysis for temperature, flow measurement, pressure and velocity is carried out

as per ASTM and ASME standards [30, 31]. The uncertainty in measurement is in the range of

±3% maximum with a confidence level of 95%.

ANNULAR COMBUSTION CHAMBER

Figure 6 Computational Domain of Annular Combustion Chamber.](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-12-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 14

Copyright © 2010 by ICFD 10

combustion stability and mixing. The fact is evident from figure 9, which shows the streamlines

from swirler outlet. Complete mixing is evident which is good for better mixing of fuel and air

inside the primary zone. Intense mixing and recirculation is observed at central core, which may

offer stable narrow flame [32, 33, 34].

Figure 8 Velocity Distributions for Non Reacting Flows.

Primary Zone = x/L < 0.4

Dilution Zone = x/L > 0.4](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-14-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 18

Copyright © 2010 by ICFD 10

The critical study of flame structure reveals that the present design offers narrow flame with

maximum temperature in primary zone being of the order of 1800 o

C. H. J. Tomczak et al. [32]

has obtained these maxima as 2330 K, T. S. Chen et al. [28] has achieved it as 2100 K while

Jinsong Hua et al. [33, 34] has reported this peak temperature in the range of 2200 to 2400 K.

Cheng et al. [28] and Jinsong et. al. [33, 34] has observed significant effect of wall boundary

condition and heat losses on flame structure and prediction of temperature levels. The narrow

and short flame structure is reported by Cheng et al. [28] with constant wall boundary condition

while reduction of peak temperature level is observed by Jinsong et al. [33, 34] with heat losses.

The intense mixing and formation of re-circulation zone at the core of primary zone are

responsible for short and narrow flame structure as is observed through flow visualization

(Figures 9), in present study.

Figure 13 Velocity Distributions (Reacting Flows).

Similar trends for velocity and pressure distribution as found for cold for studies are found with

reacting flow studies (figures 13 and 14). However, the velocity and pressure levels are slightly](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-18-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 19

Copyright © 2010 by ICFD 10

higher for reacting flows. It is important to note that the pressure drop across the combustion

chamber is around 10% of the inlet pressure which is quite tune with the published results for

tubular combustion chamber. CFD and experimental results qualitatively match while

quantitatively the results differ by around 20%. Similar results are obtained by Grinstein &

Fureby [7] for velocity profiles in LM6000 combustor.

Figure 14 Pressure Distributions (Reacting Flows).

ANNULAR COMBUSTION CHAMBER

An appropriate fluid flow texture is critical important for stable combustion in the liner, which

ensures proper fuel concentration field in the combustor and air distribution among the dilution

holes and tiny film-cooling holes [35]. The numerical simulation is carried out using SST k – ω

turbulence model with inlet boundary conditions of mass flow rates of air and fuel. The outlet is

taken as opening type with relative pressure at outlet of 0 Pa.](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-19-2048.jpg)

![Proceedings of ICFD 10:

Tenth International Congress of Fluid Dynamics

December 16-19, 2010, Stella Di Mare Sea Club Hotel, Ain Soukhna, Red Sea, Egypt

ICFD10-EG-30I3

Keynote Speakers: Dr. S. A. Channiwala & Dr. Digvijay B. Kulshreshtha Page 21

Copyright © 2010 by ICFD 10

Actually, the back flow zones can be regarded the areas where the fuel are ignited and the

combustion flame is stably held, or the flow back zones serve as igniters and flame-holder while

the CRVP downstream the second pair of the dilution holes may be a cut-valve to the flame. The

flow behavior in the combustor, including the flow back zones, eddies, and their size and

intensity, will apparently control the combustion behavior and then the performance of the

engine. The simulation and experimental results indicate the main inlet flow plays a critically

important role in forming a very well organized combustion, while the flows from the dilution

holes further assist and complete fuel combustion in later stage [18].

Figure 16 Normalized Distributions of Velocity and Pressure in Pre-diffuser Section.

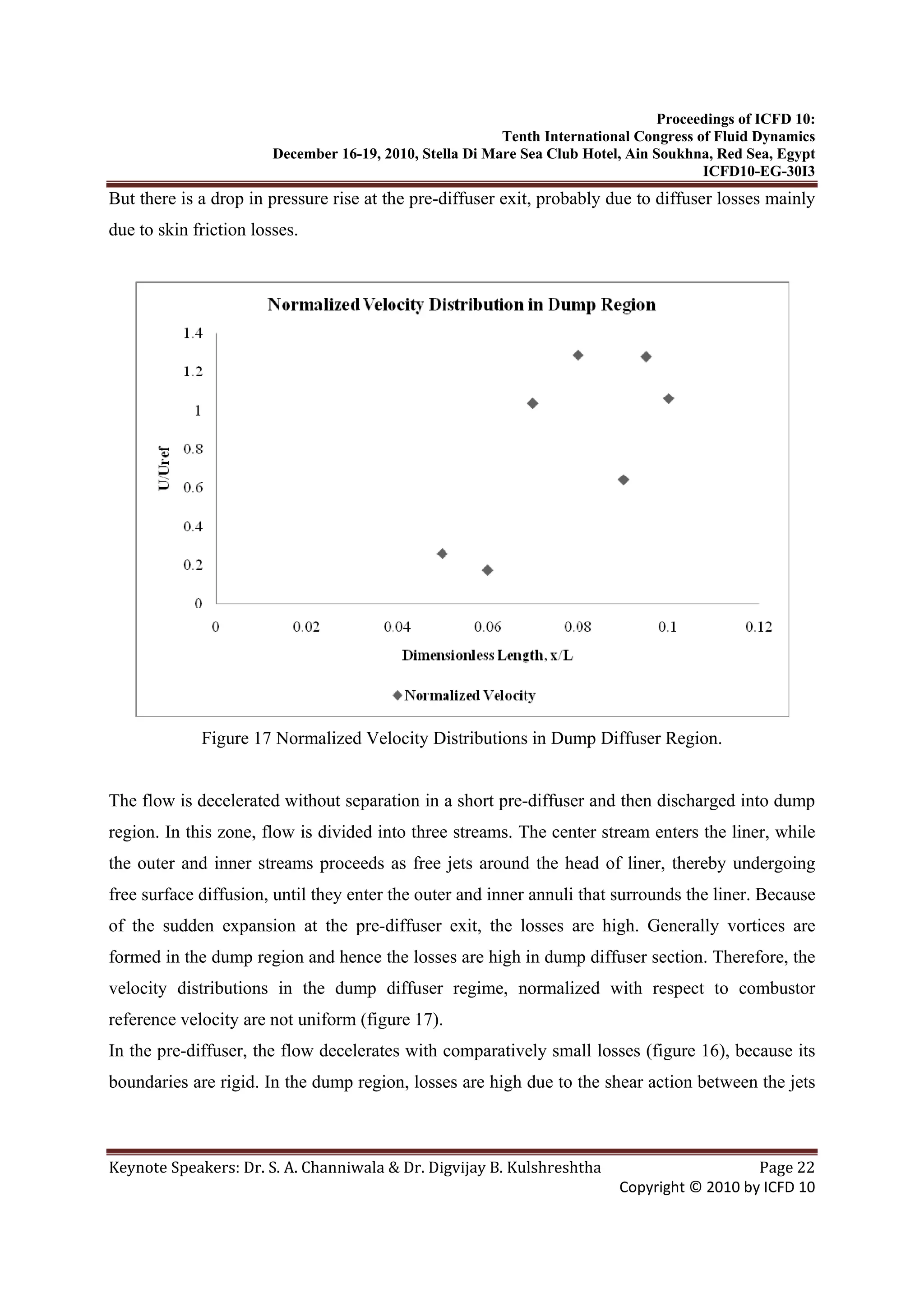

Figure 16 shows the velocity and pressure distributions in the pre-diffuser section, normalized

with the combustor reference velocity and inlet pressure, respectively. The inlet velocities are

higher compared to the reference velocity and thereafter the values decreases gradually. This is

mainly due to flow diffusion leading to drop in velocity gradient and rise in pressure gradient.](https://image.slidesharecdn.com/combustion-chamber-liners-150619141027-lva1-app6892/75/Combustion-chamber-liners-21-2048.jpg)