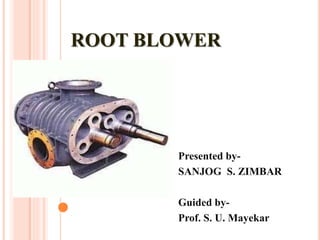

This document summarizes the root blower, a type of positive displacement supercharger. It discusses the history, construction, working, types (twin lobe and three lobe), advantages, and disadvantages. Root blowers work by using rotating lobes to trap air and transport it from an intake to exhaust port. While they can deliver large air flows, they also experience more vibration and noise than other supercharger types. Root blowers are commonly used in automobiles and diesel engines where a large volume of air needs to be moved with minimal pressure increase.