This document provides a project plan for constructing a compressed natural gas (CNG) station in Barakao, Pakistan by Medgulf Construction Company. The plan outlines the project scope, timeline, budget, and management approach over 12 phases. The goal is to construct a CNG station that can fill 12 cars simultaneously with additional facilities, at an estimated cost of Rs23.1 million over a 1.2 year timeframe starting January 2011. The scope involves procuring materials, constructing buildings and installing CNG equipment. Project requirements, a scope statement, and work breakdown structure are defined to map out the project.

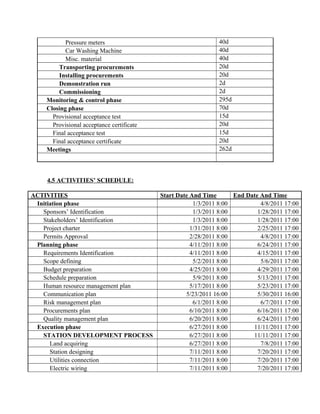

![84. Final acceptance certificate 83

85. Meetings

86. 10 Monthly meetings

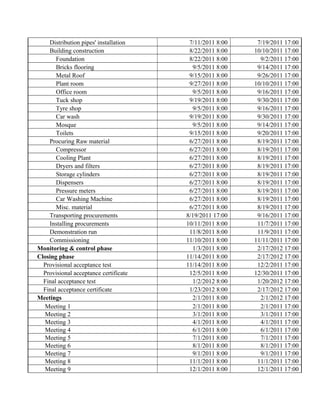

4.3 ESTIMATED ACTIVITIES’ RESOURCES:

ACTIVITY RESOURCES

Initiation phase

Project Management Team(excluding Project manager and

Assistant)[50%],Functional ,Support

personnels[30%],Project manager[20%]

Sponsors Identification

Stakeholders Identification

Project charter

Permits Approval

Planning phase

Project Management Team(excluding Project manager and

Assistant)[20%],Assistance

manager[20%],Engineers[20%],Installation

team[20%],Project manager[20%]

Requirements Identification

Scope defining

Budget preparation

Schedule preparation

Human resource management plan

Communication plan

Risk management plan

Procurements plan

Quality management plan

Execution phase

STATION DEVELOPMENT PROCESS

Land acquiring Assistance manager, LAND[1]

Station designing

Project Management Team(excluding Project manager and

Assistant)[25%],Map Designer[75%]

Utilities connection Assistance manager

Electric wiring Electrician[50%],Technicians[50%]

Distribution pipes' installation Plumber[50%],Mechanic[50%]

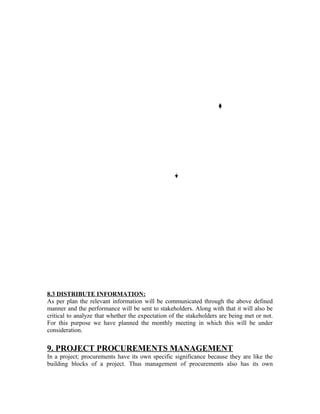

Building construction

Foundation Lower class Labor group 1[50%],Mason 1 (waqas)[50%]

Bricks flooring Lower class Labor group 1[50%],Mason 1 (waqas)[50%]

Metal Roof Mason 2 (waqar)[50%],Lower class Labor group 1[50%]

Plant room Mason 2 (waqar)[50%],Lower class Labor group 2[50%]](https://image.slidesharecdn.com/pp-athar-bo8-018-131003113912-phpapp02/85/CNG-station-construction-project-report-14-320.jpg)

![Office room Mason 3 (Waseem)[50%],Lower class Labor group 3[50%]

Tuck shop Mason 3 (Waseem)[50%],Lower class Labor group 3[50%]

Tyre shop Mason 4 (Wajid)[50%],Lower class Labor group 4[50%]

Car wash Mason 4 (Wajid)[50%],Lower class Labor group 4[50%]

Mosque Mason 5 (wazir)[50%],Lower class Labor group 5[50%]

Toilets Mason 5 (wazir)[50%],Lower class Labor group 5[50%]

Procuring Raw material

Compressor Compressor[1]

Cooling Plant Cooling Plant[1]

Dryers and filters Dryers and filters[1]

Storage cylinders Storage cylinders[1]

Dispensers Dispensers[1]

Pressure meters Pressure meters[1]

Car Washing Machine Car Washing Machine[1]

Misc. material Misc. material[1]

Transporting procurements

Lower class Labor group 1[50%],Lower class Labor group

2[50%]

Installing procurements Engineers[25%],Installation team[25%],Mechanic[50%]

Demonstration run Assistance manager[50%],Installation team[50%]

Commissioning

Project Management Team(excluding Project manager

manager and Assistant)[50%],Project manager[50%]

Monitoring & control phase

Project Management Team(excluding Project manager

manager and Assistant)[60%],Project manager[40%]

Closing phase

Provisional acceptance test

Functional Support personnels[30%],Project Management

Team(excluding Project manager and Assistant)

[30%],Project manager[30%]

Provisional acceptance certificate

Functional Support personnels[30%],Project Management

Team(excluding Project manager and Assistant)

[30%],Project manager[30%]

Final acceptance test

Functional Support personnels[30%],Project Management

Team(excluding Project manager and Assistant)

[30%],Project manager[30%]

Final acceptance certificate

Functional Support personnels[30%],Project Management

Team(excluding Project manager and Assistant)

[30%],Project manager[30%]

Meetings

Project Management Team(excluding Project manager and

Assistant)[15%],Functional Support personnels[10%],Project

manager[75%]

4.4 ESTIMATED ACTIVITY DURATIONS:](https://image.slidesharecdn.com/pp-athar-bo8-018-131003113912-phpapp02/85/CNG-station-construction-project-report-15-320.jpg)