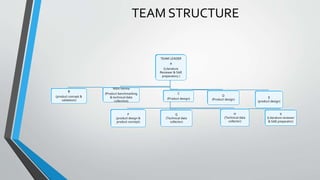

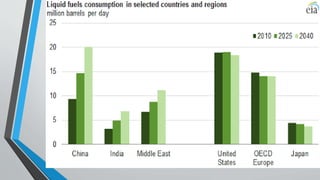

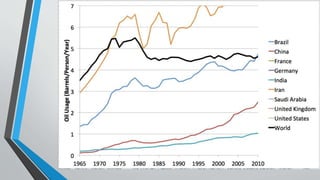

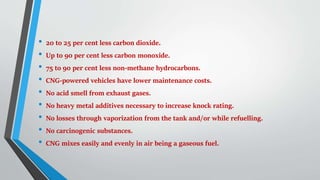

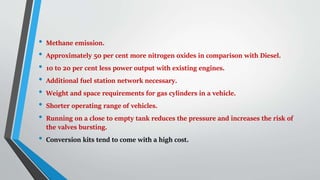

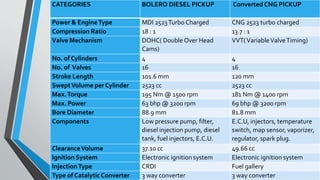

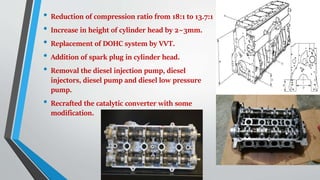

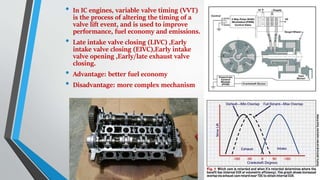

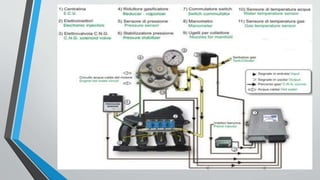

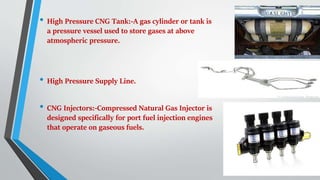

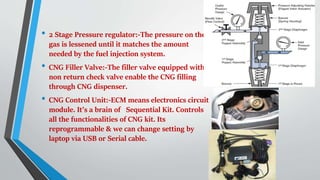

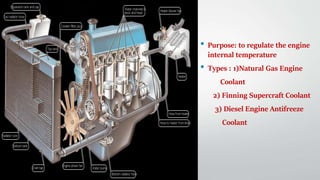

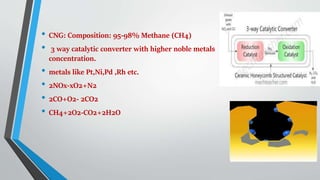

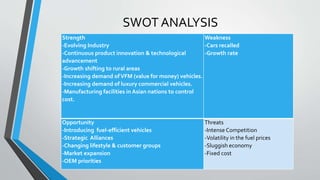

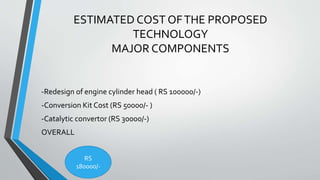

The document outlines a case study on converting a diesel engine to a CNG engine to comply with new emission norms, detailing the team structure and market trends for natural gas vehicles. It highlights the advantages of CNG, including lower emissions and maintenance costs, alongside disadvantages such as methane emissions and reduced power output. Additionally, the document includes technical specifications, a SWOT analysis, details on the proposed technology costs, and a marketing concept for the new product.