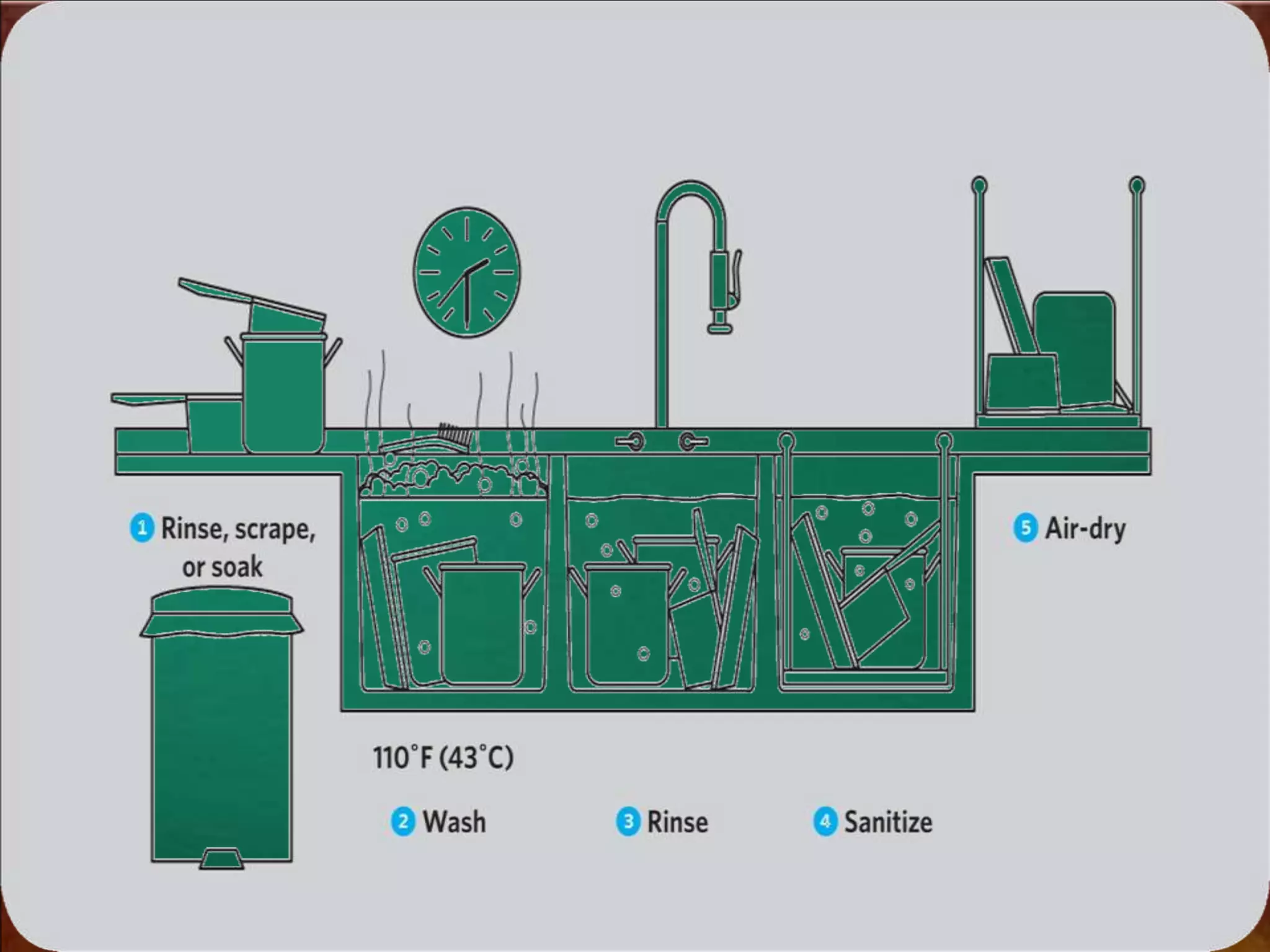

Cleaning and sanitizing procedures are essential parts of a food safety program. Cleaning removes food and other soils using the appropriate cleaning agent, while sanitizing reduces microorganisms using heat, chemicals, or both. Common sanitizing methods include hot water above 77C, steam, or chemical sanitizers like chlorine, iodine, or quaternary ammonium which must be used at the proper concentration and contact time. Proper cleaning and sanitizing of utensils and surfaces is necessary to prevent foodborne illness.