This document discusses stress-strain curves for concrete and steel reinforcement. It provides details on:

1) The stress-strain curve properties for concrete in compression, including the initial slope, ascending parabola, strain at maximum stress, descending parabola, and strain at failure.

2) Methods for determining the tensile strength of concrete, including flexure and split cylinder tests.

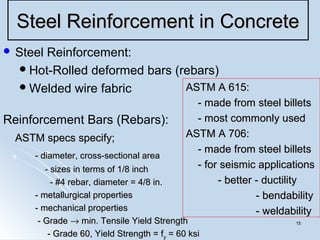

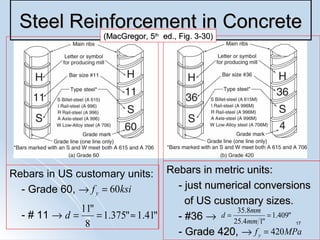

3) The use of steel reinforcement bars and welded wire fabric to prevent brittle failure in concrete by taking up tension stresses. Properties of reinforcement bars like diameter, grade, and modulus of elasticity are defined.

4) Factors that affect the yield strength and fatigue strength of steel reinforcement, such as temperature

![55

Stress-Strain Curve for CompressionStress-Strain Curve for Compression

Lightweight Concrete ;

ACI 318, Sect. 8.5, 8.6

sensitive to Eaggregate .

For all parameters involving

Each parameter shall be multiplied by a modification factor

for sand-lightweight conc.

for all-lightweight concrete

If splitting tensile strength, fct , is specified, then

This accounts for the reduced

capacity of lightweight concrete

due to aggregate failure;

Such as:

Shear strength

Splitting resistance

Concrete-rebar bond

For normal weight concrete the averageFor normal weight concrete the average

splitting tensile strength is;splitting tensile strength is;

( )[ ] 0.17.6/ '

≤= cct ffλ

'

cf

( )'

7.6 cct ff ≈

(MacGregor, 5(MacGregor, 5thth

ed., Fig. 3.26)ed., Fig. 3.26)

( ) ( )

( ) '5.1

33

33

12090

ccc

c

fwpsiE

FtLbwFtLb

=

≤≤

75.0

85.0

=

=

λ

λ

λ](https://image.slidesharecdn.com/class27-160420075947/85/Civil-Engineering-Materials-5-320.jpg)