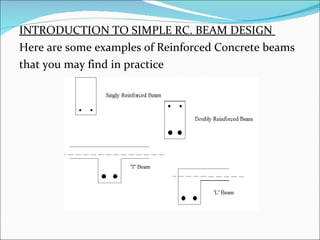

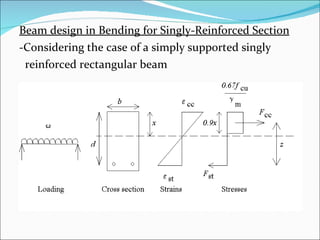

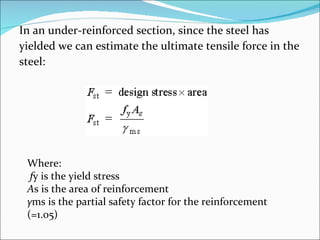

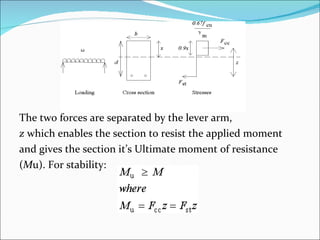

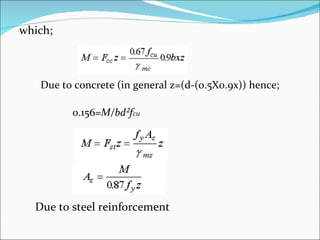

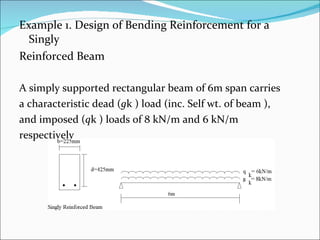

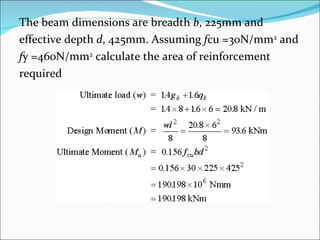

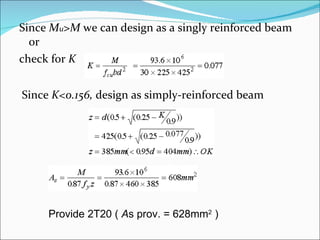

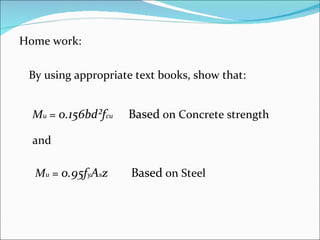

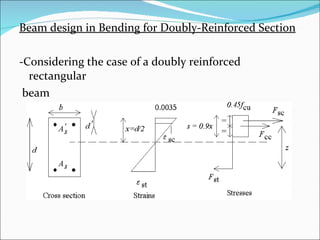

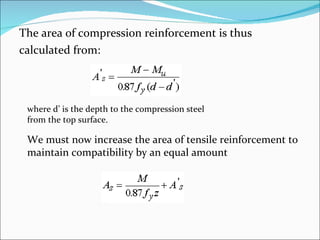

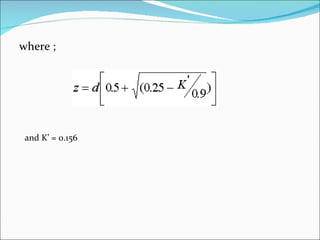

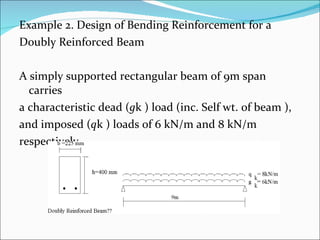

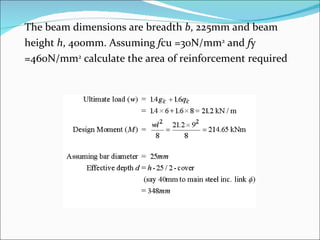

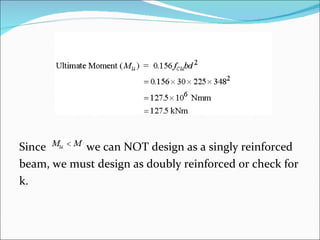

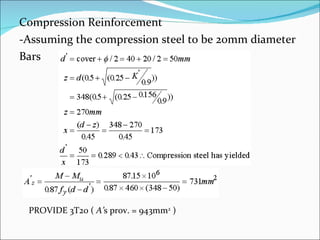

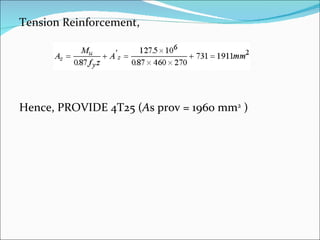

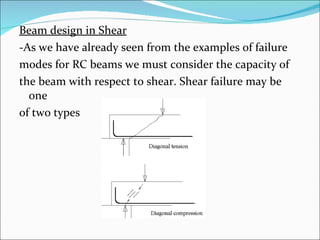

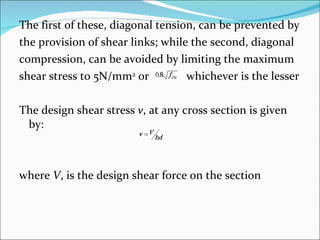

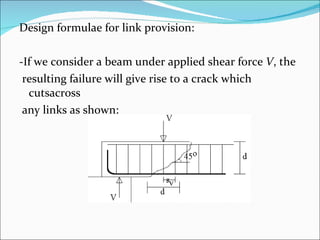

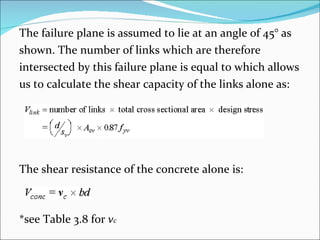

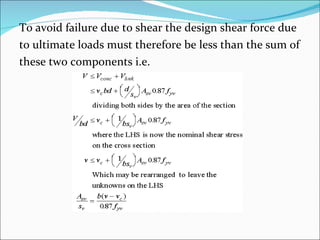

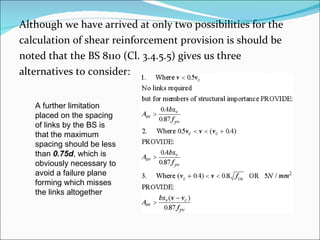

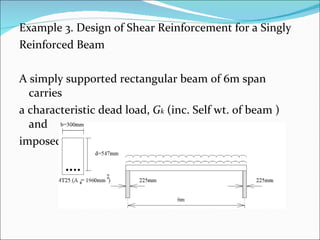

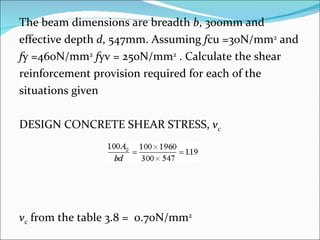

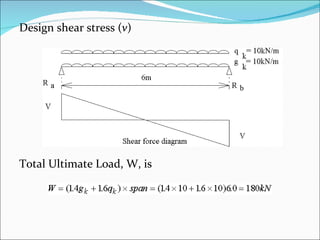

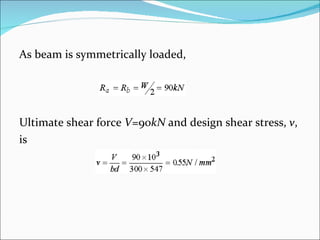

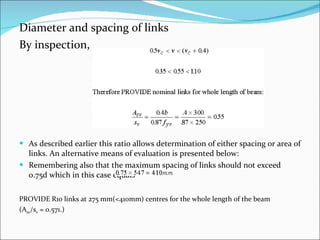

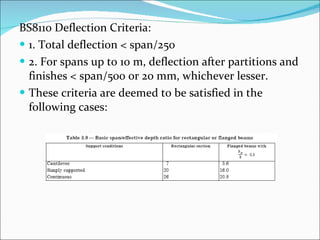

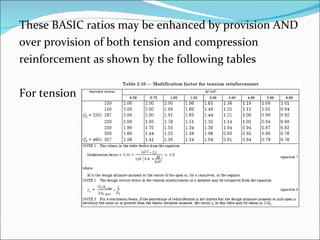

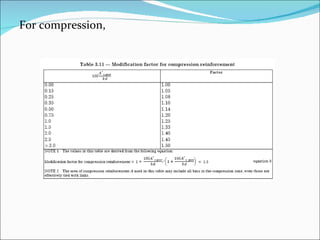

The document discusses the design of reinforced concrete beams for bending and shear. It covers the analysis of singly and doubly reinforced rectangular beam sections. Key points covered include the concept of neutral axis, under-reinforced and over-reinforced sections, design of bending reinforcement, design of shear reinforcement including link spacing, and deflection criteria. Worked examples are provided to demonstrate the design of bending and shear reinforcement for rectangular beams.