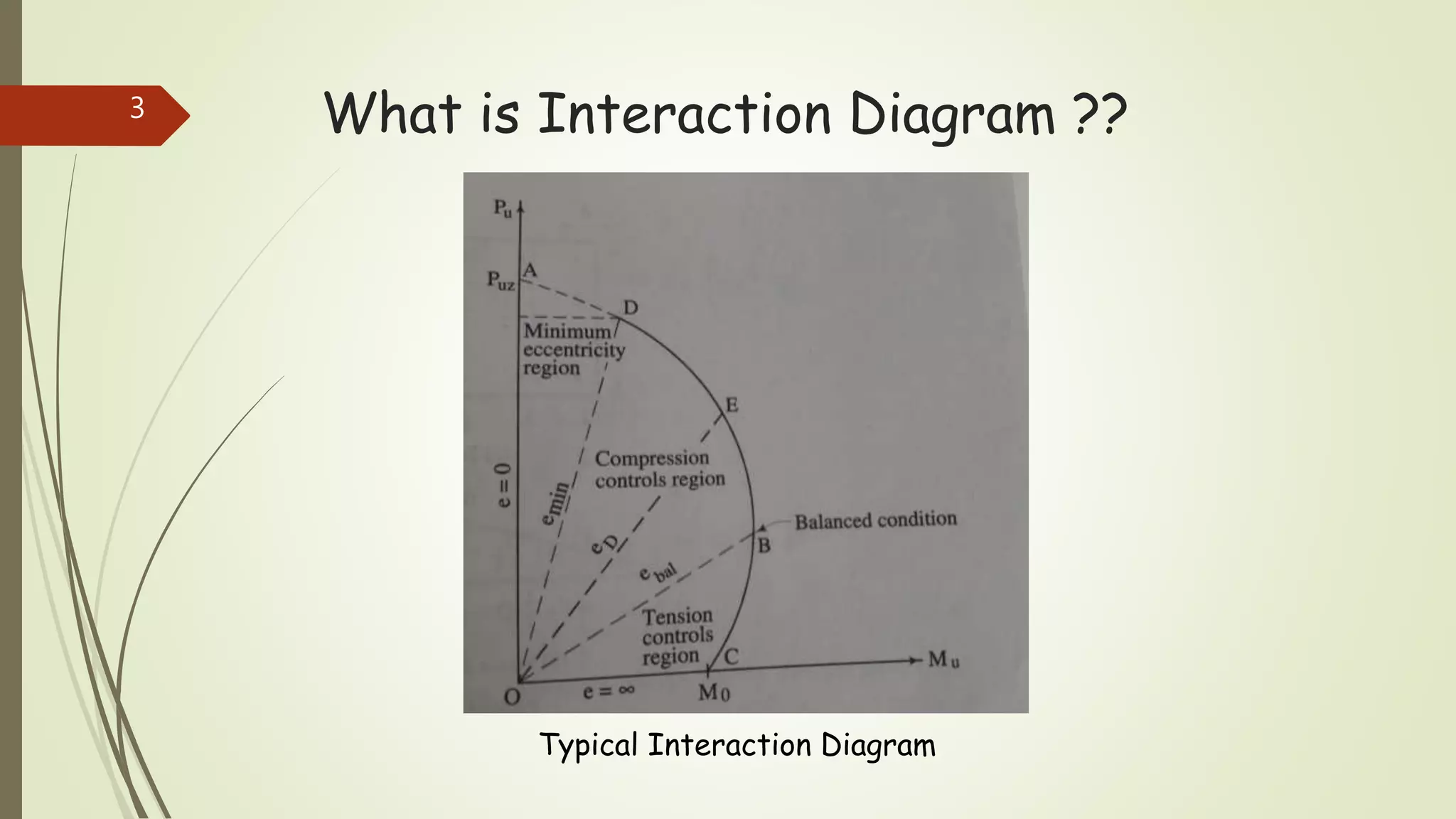

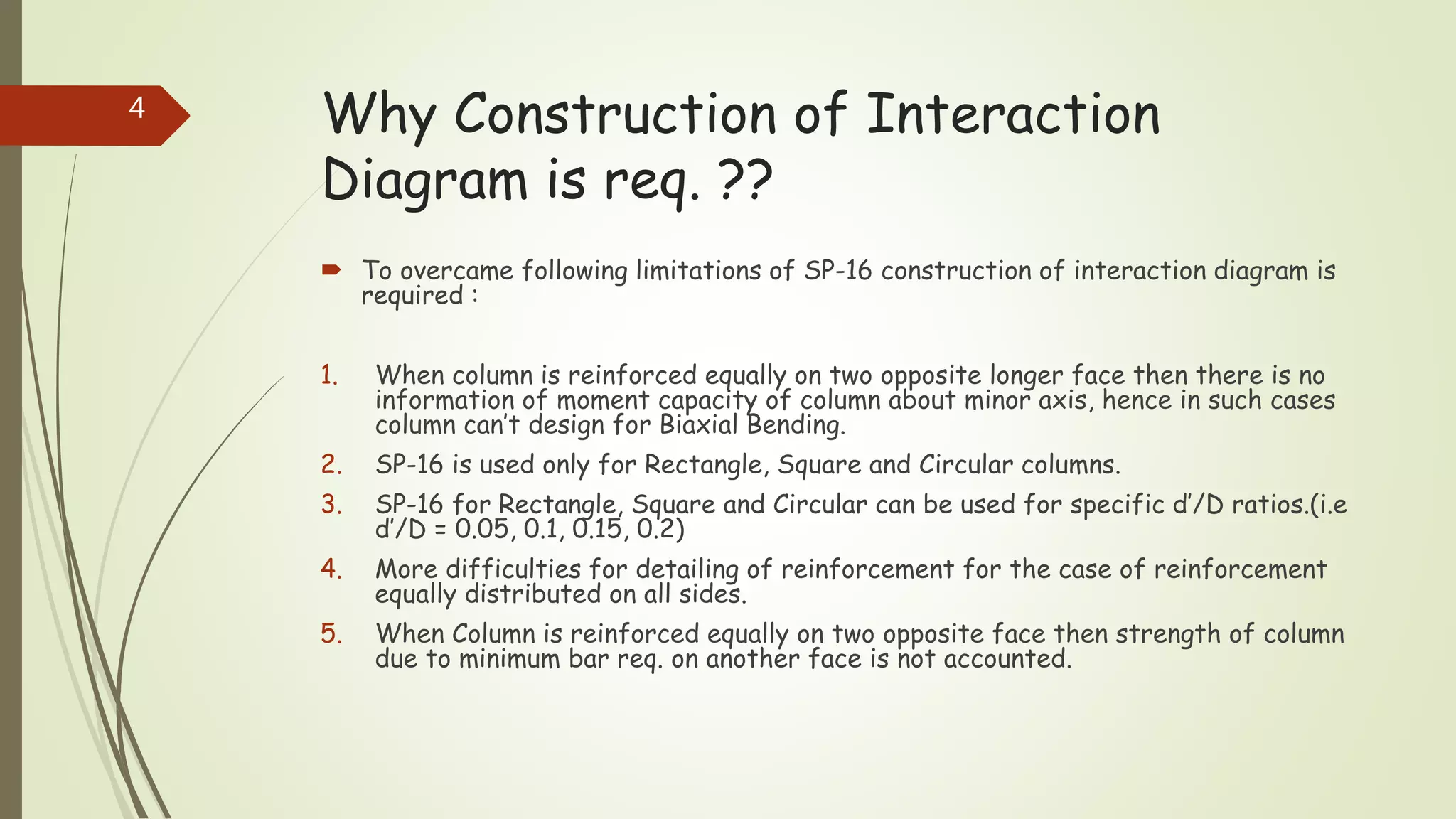

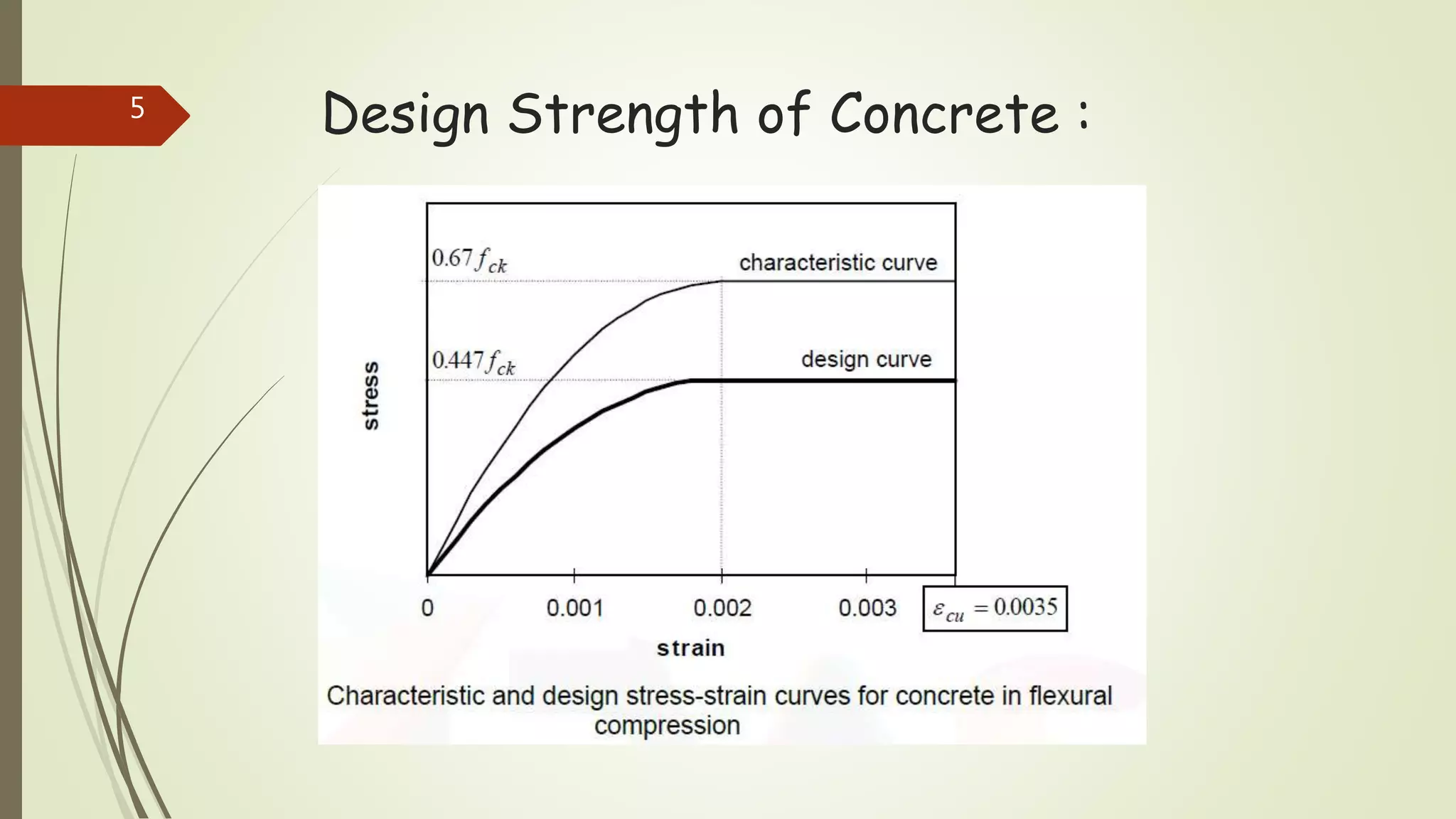

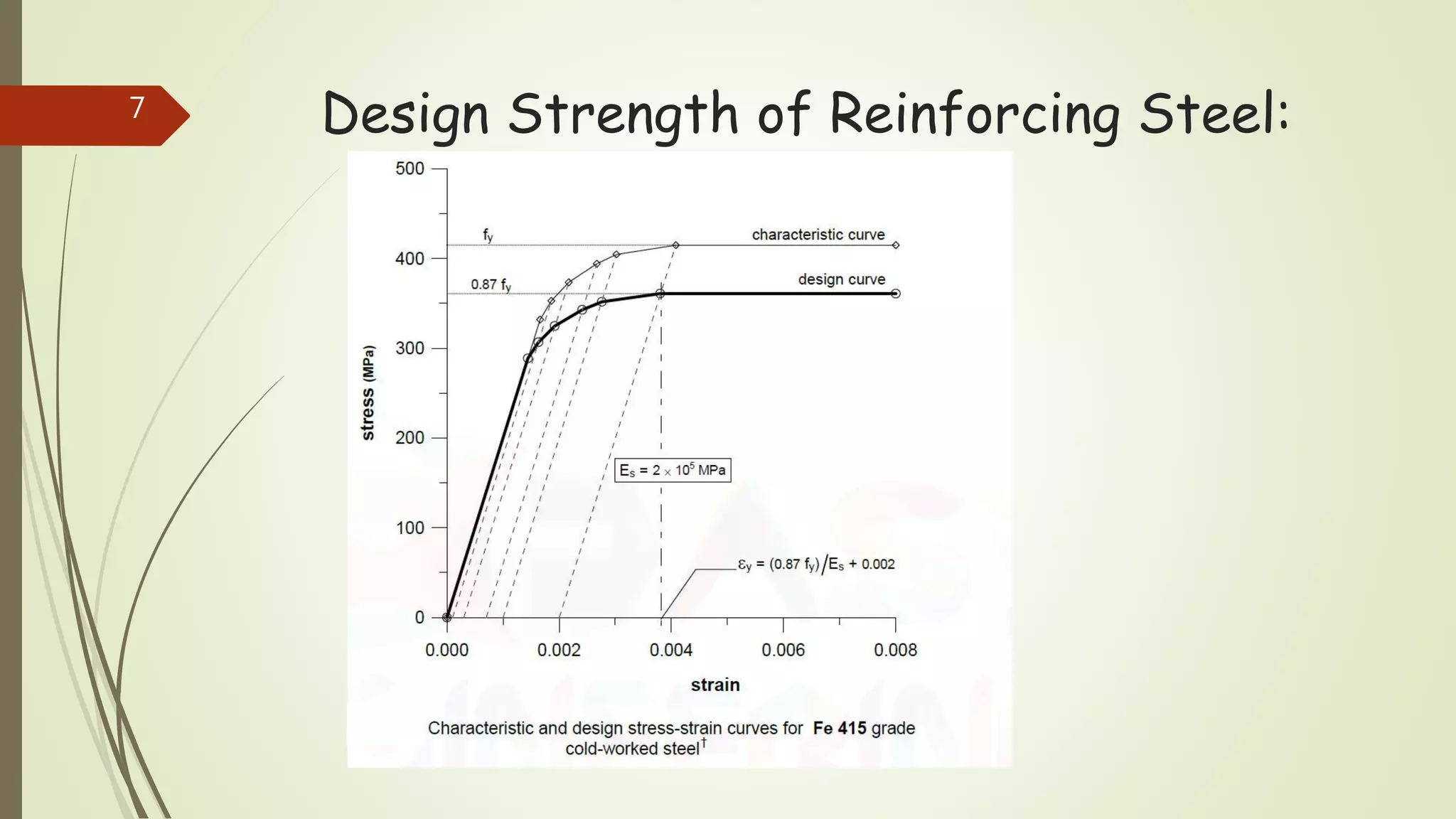

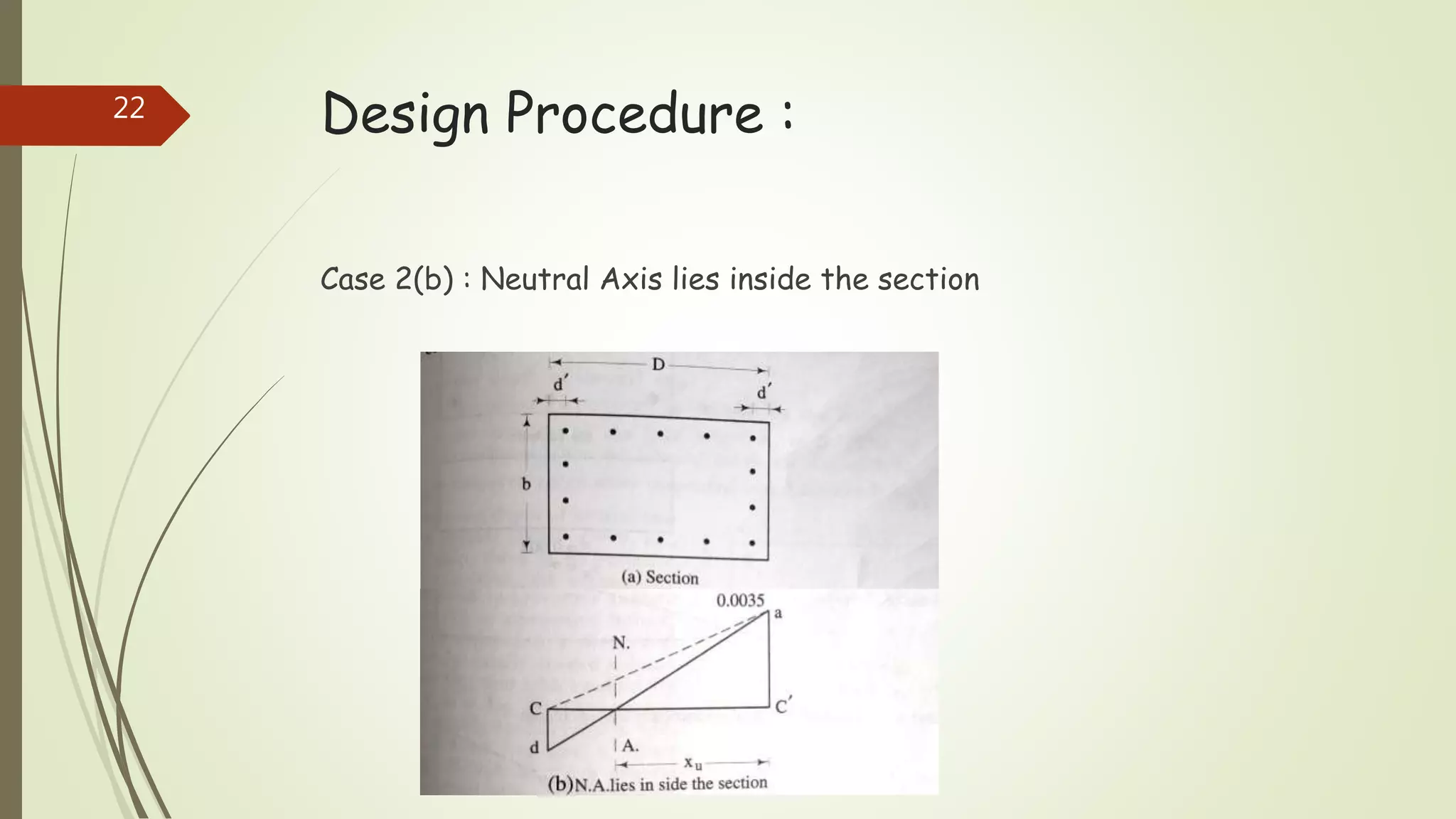

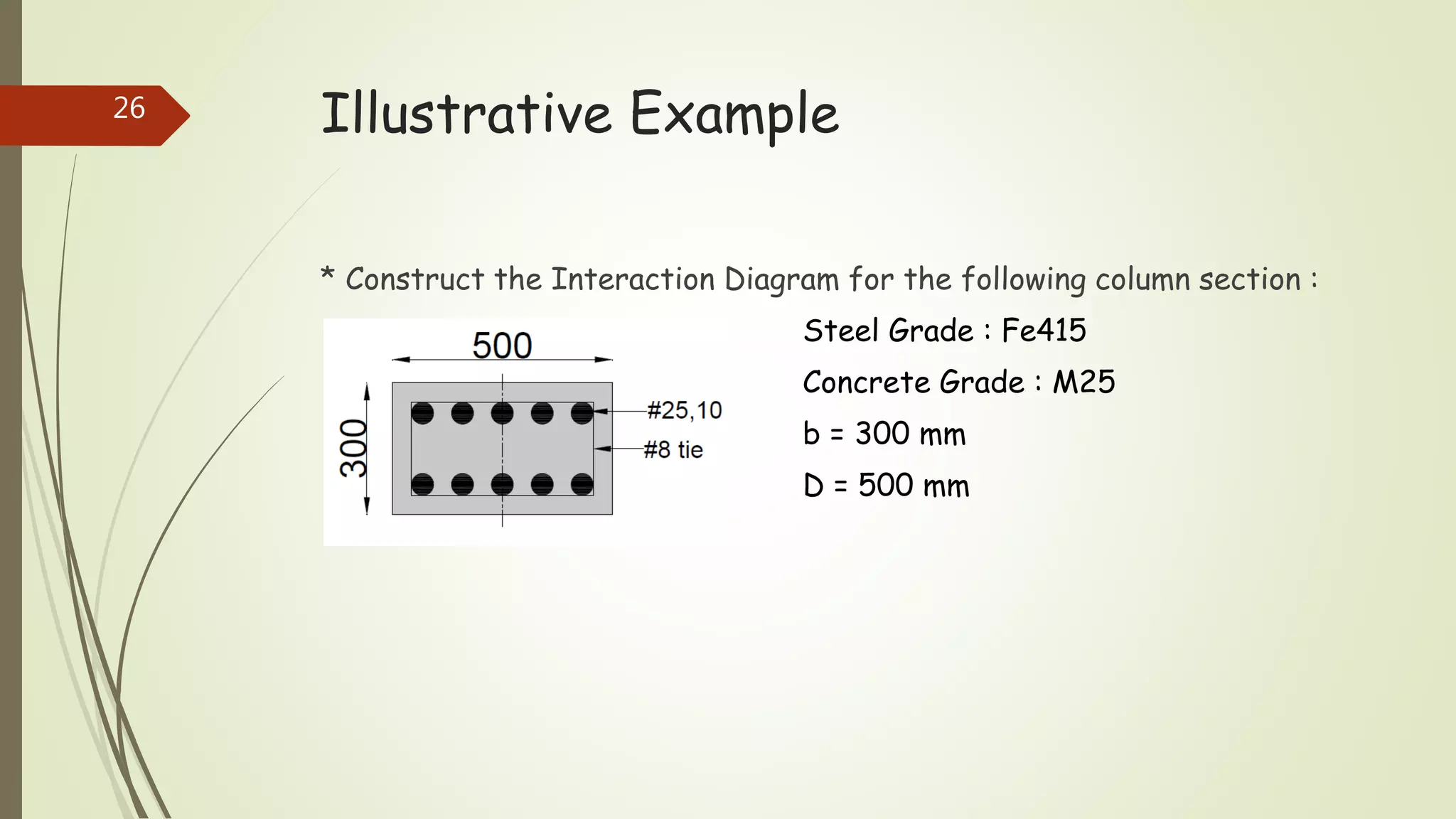

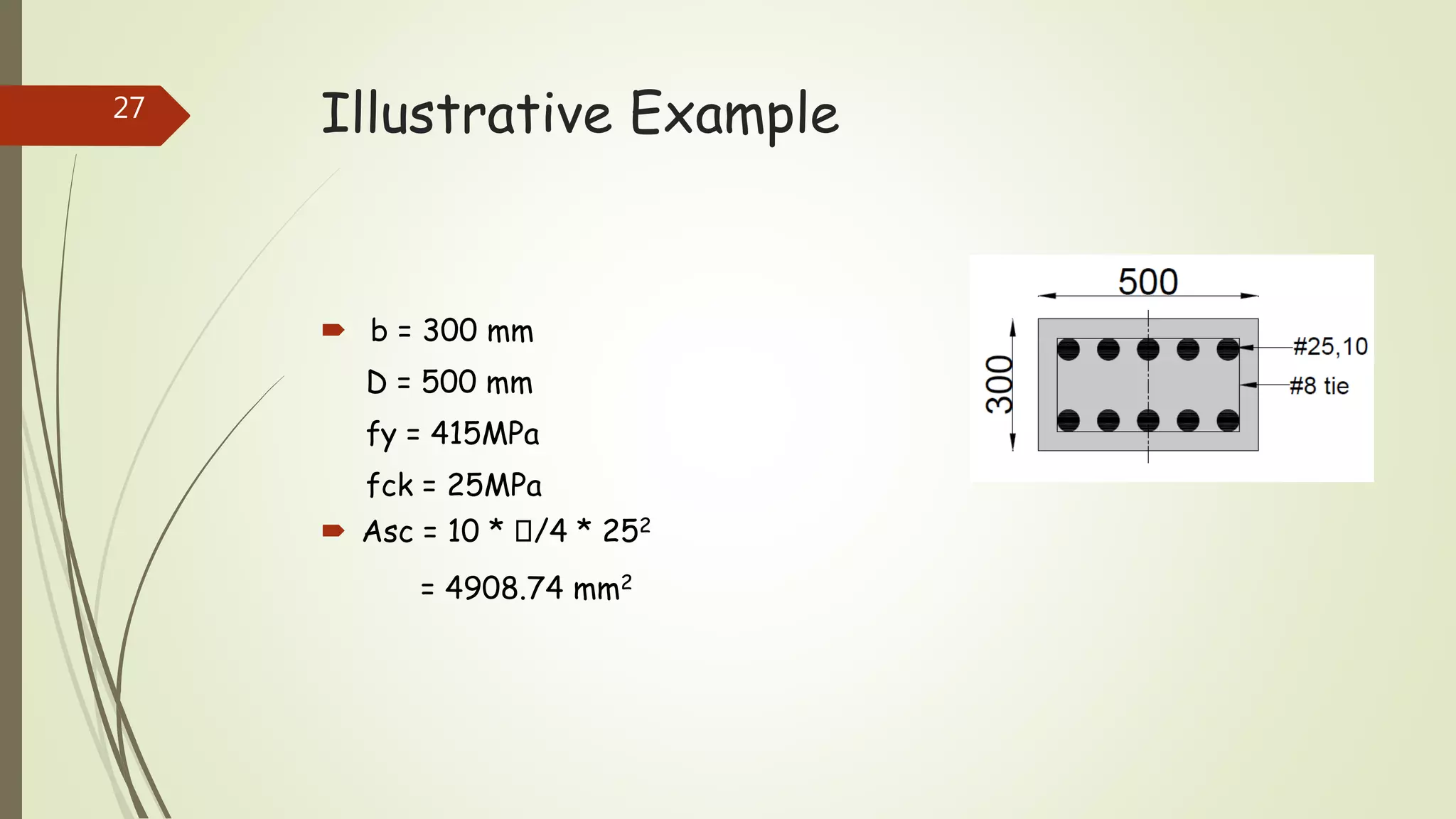

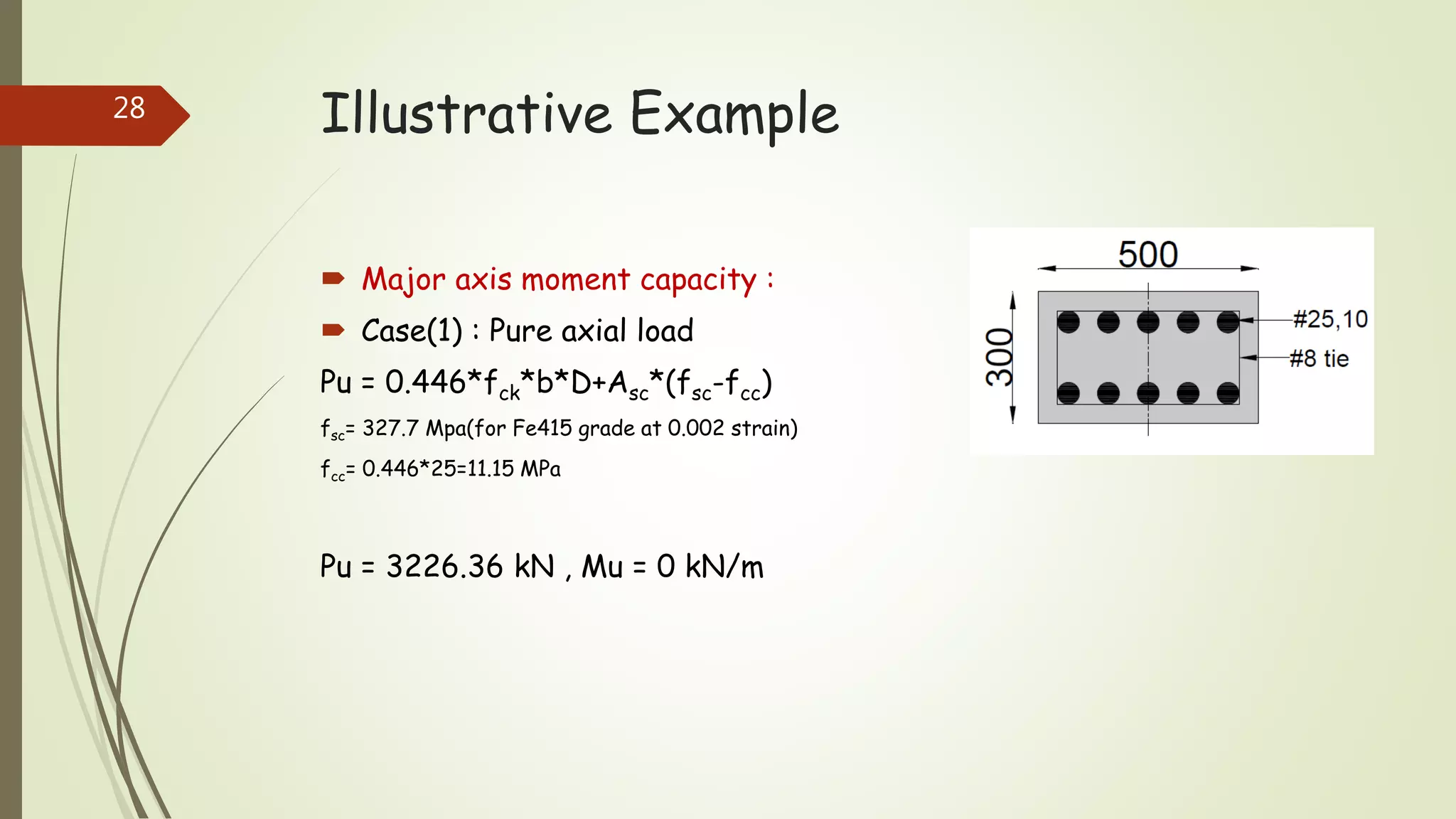

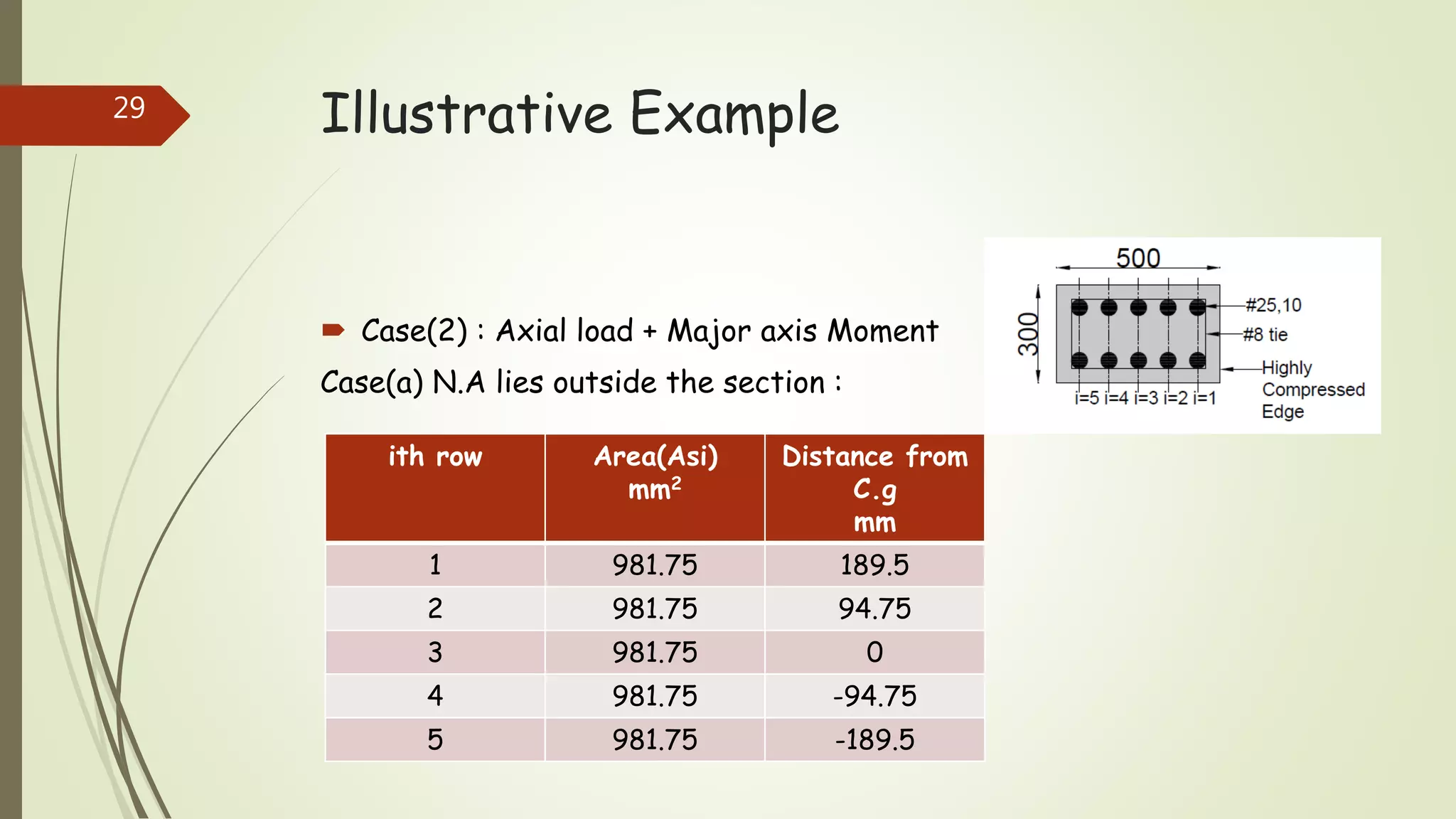

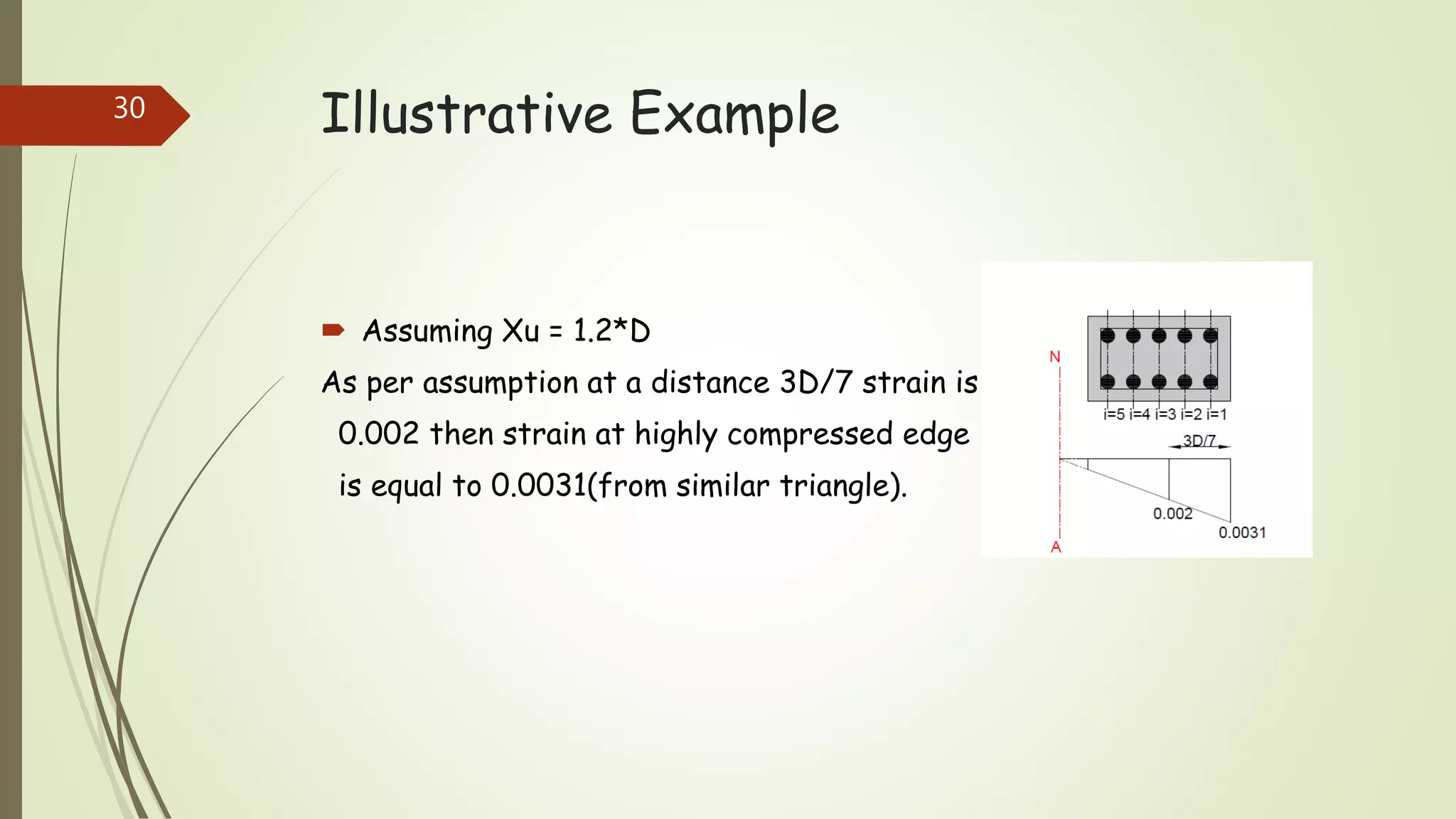

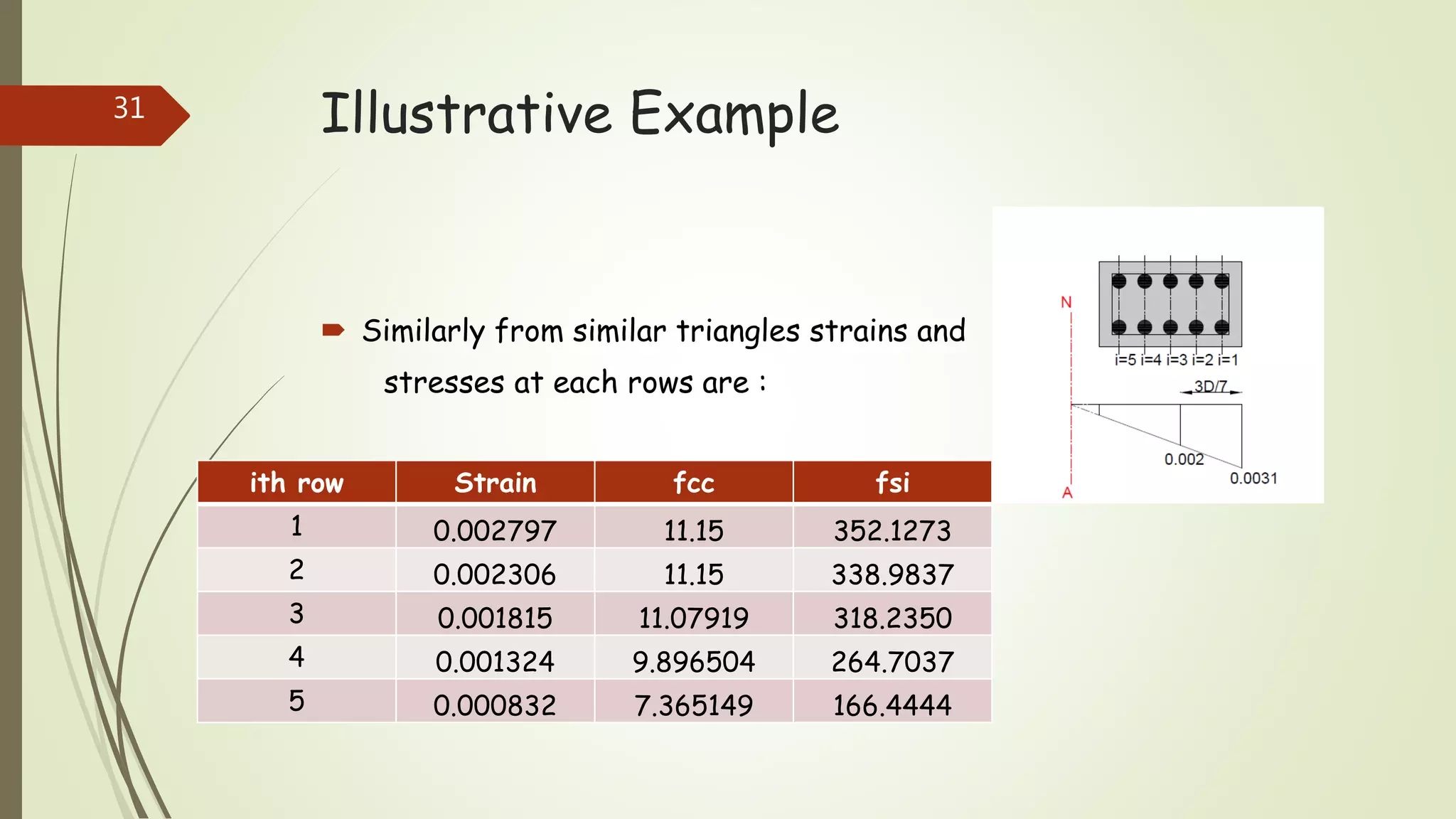

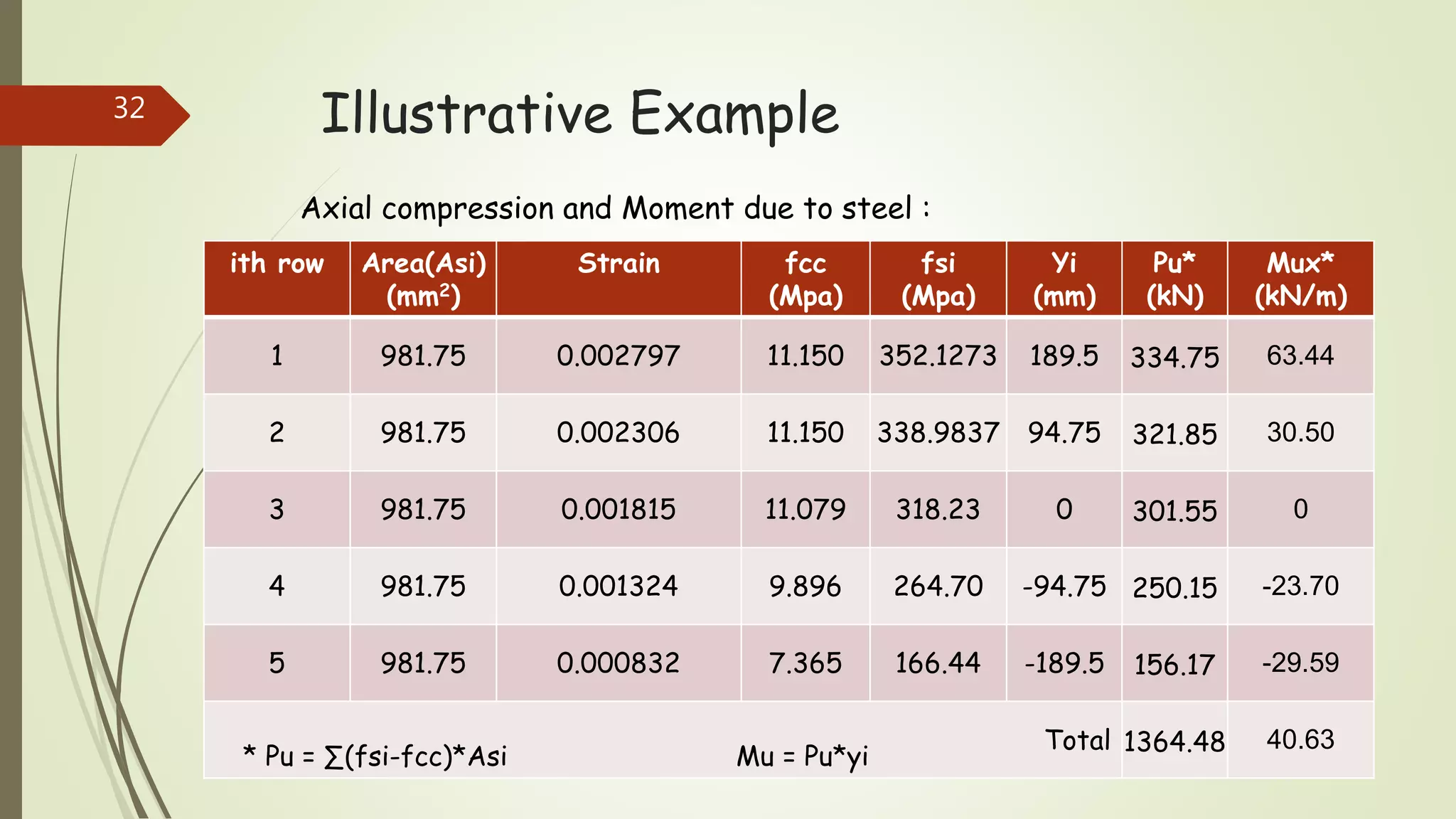

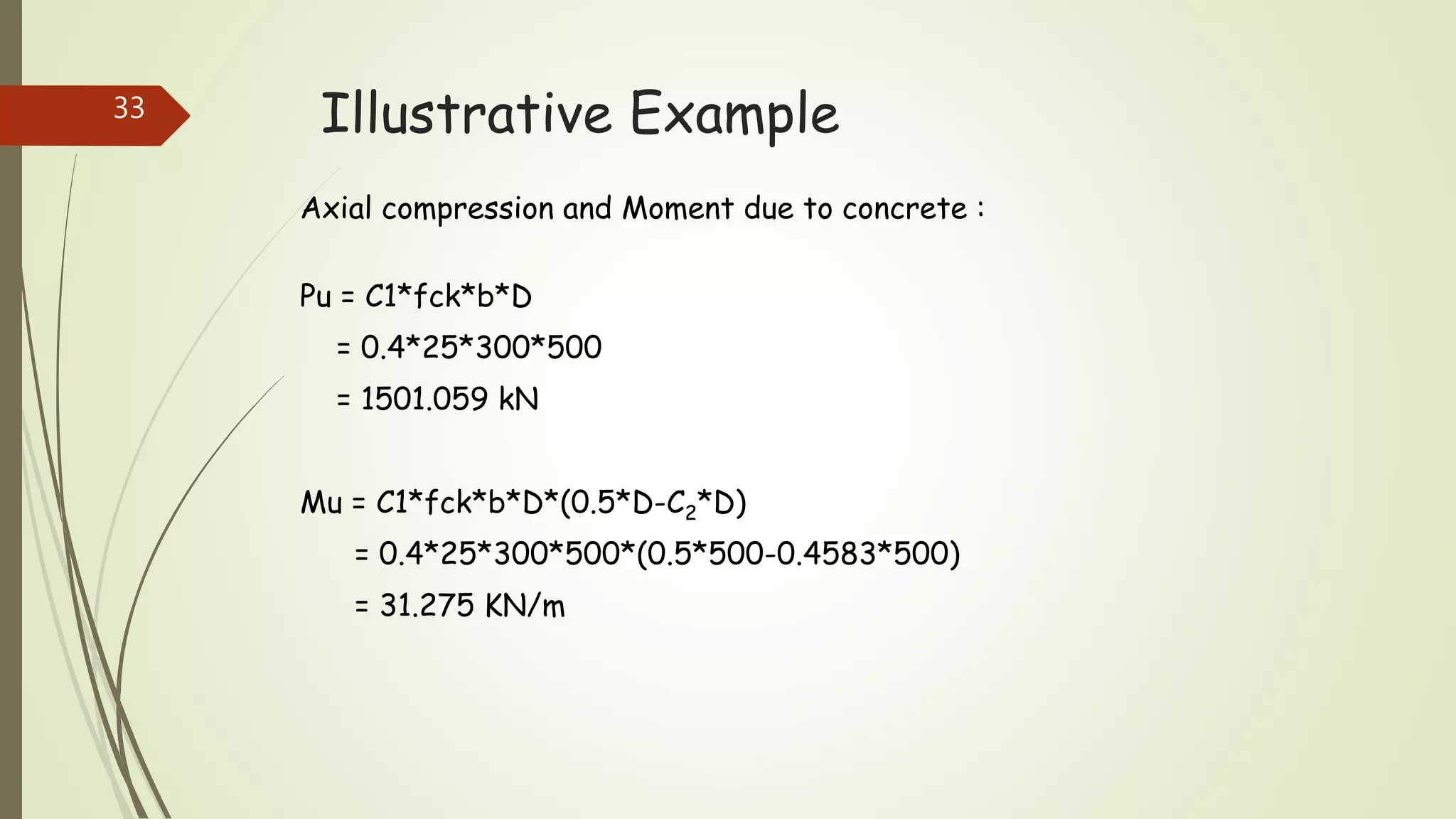

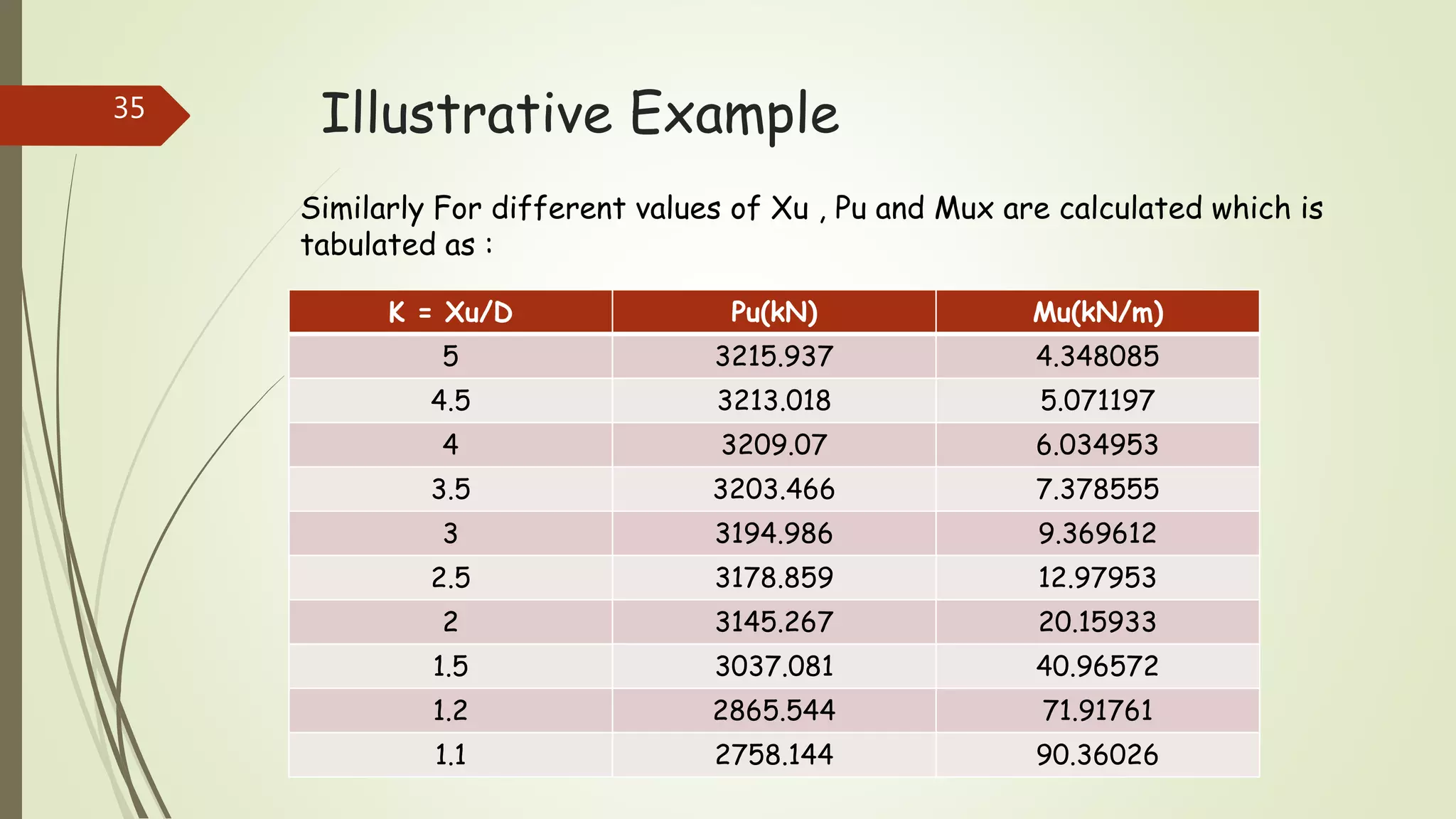

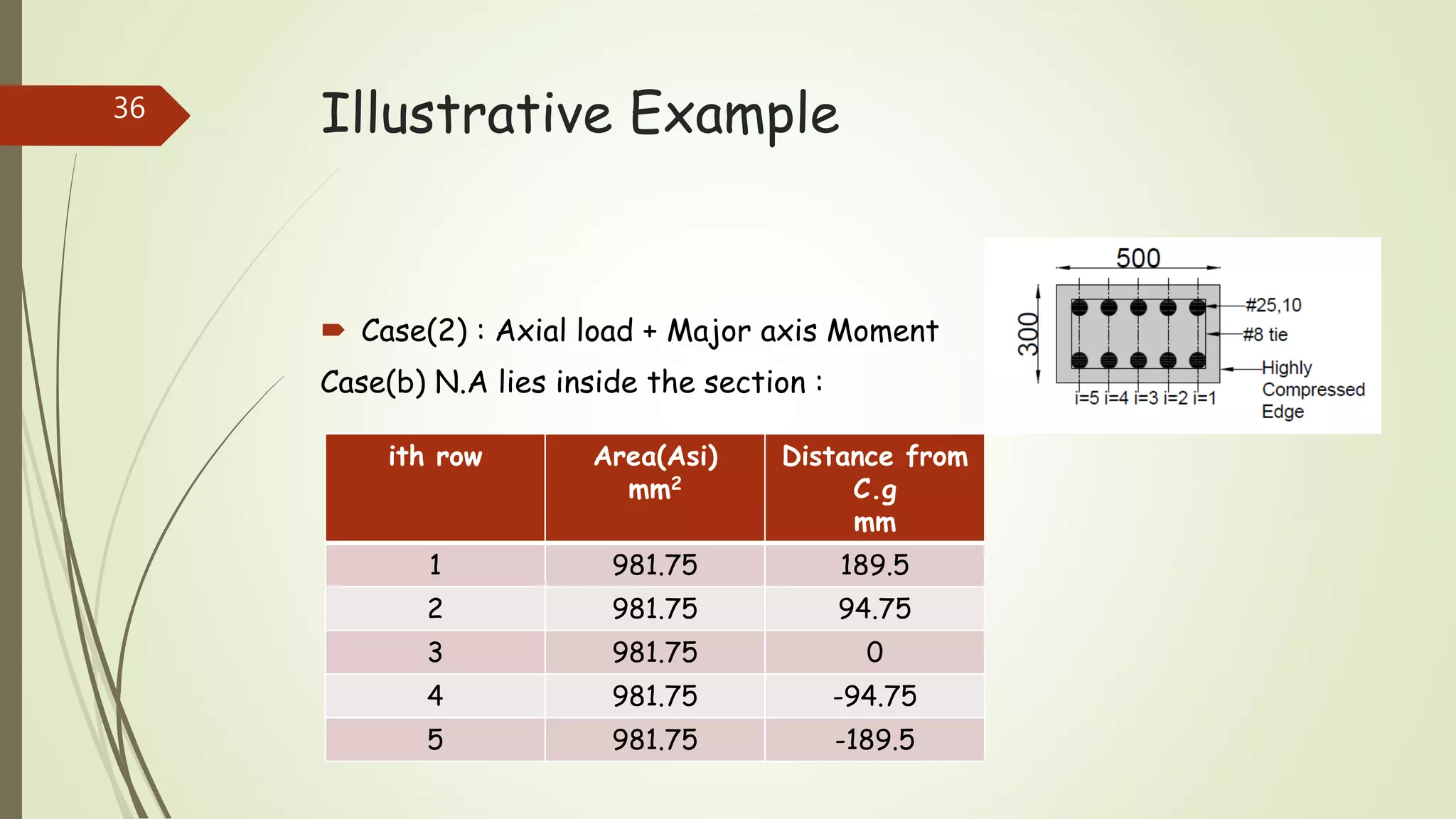

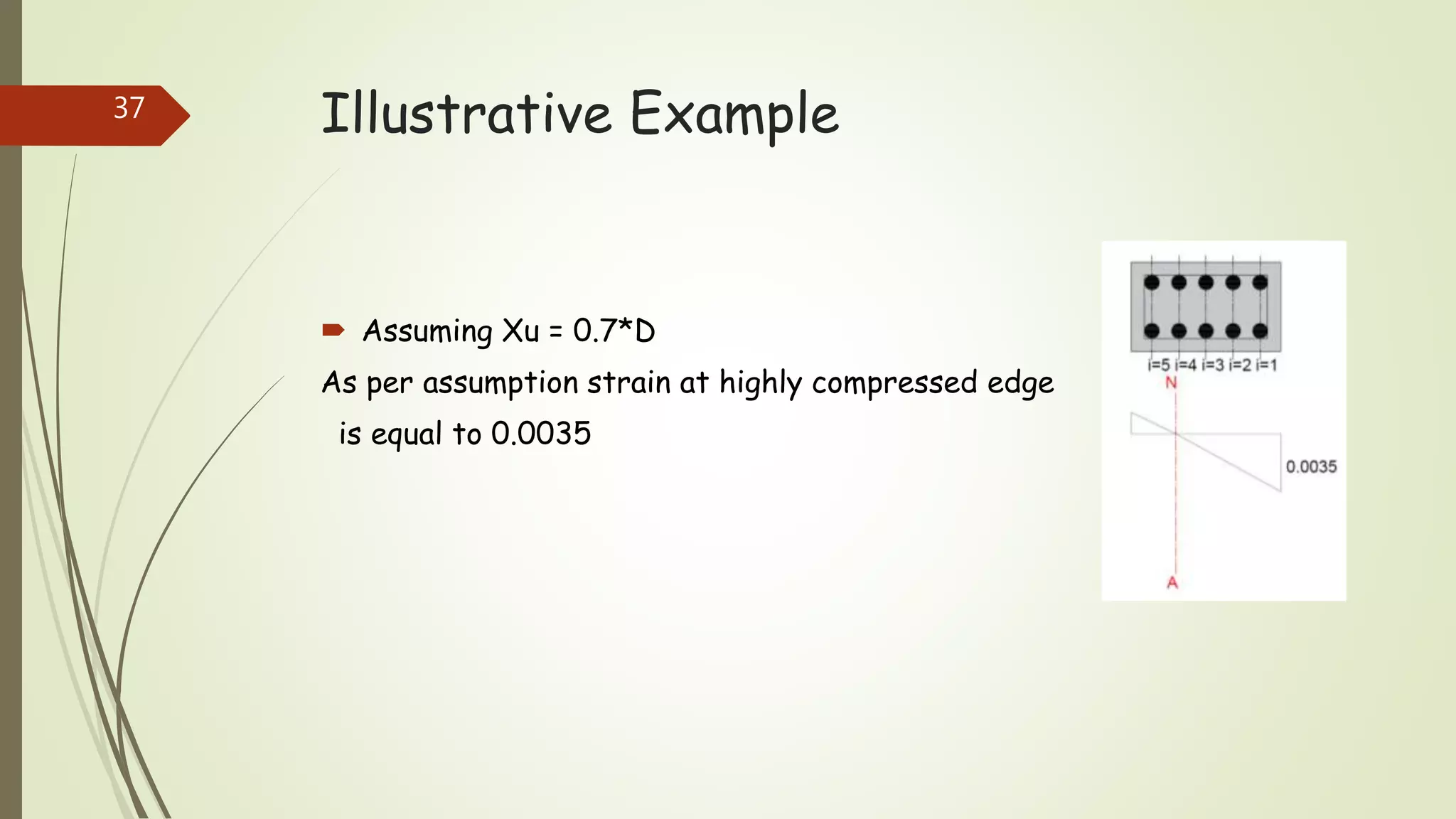

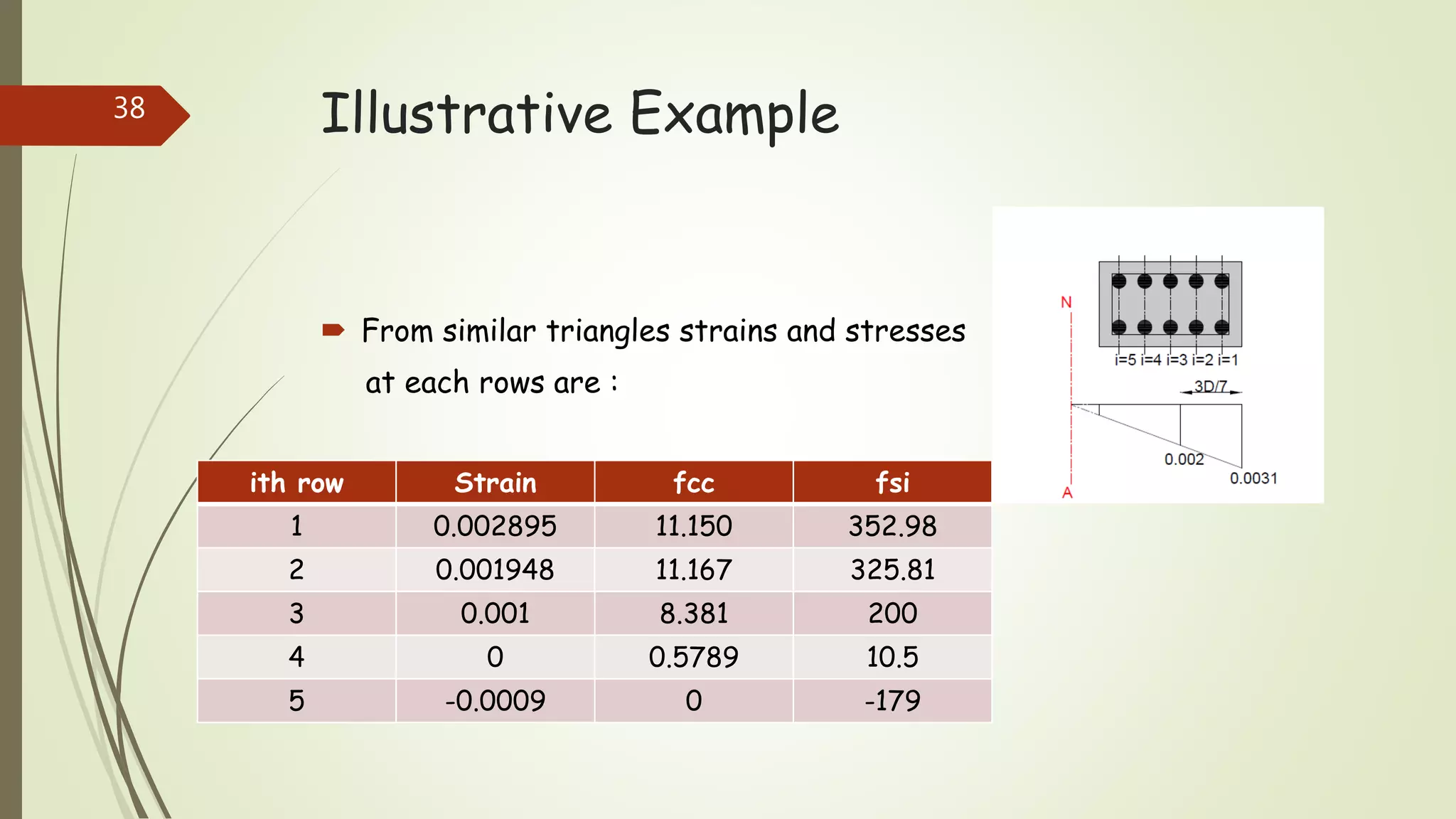

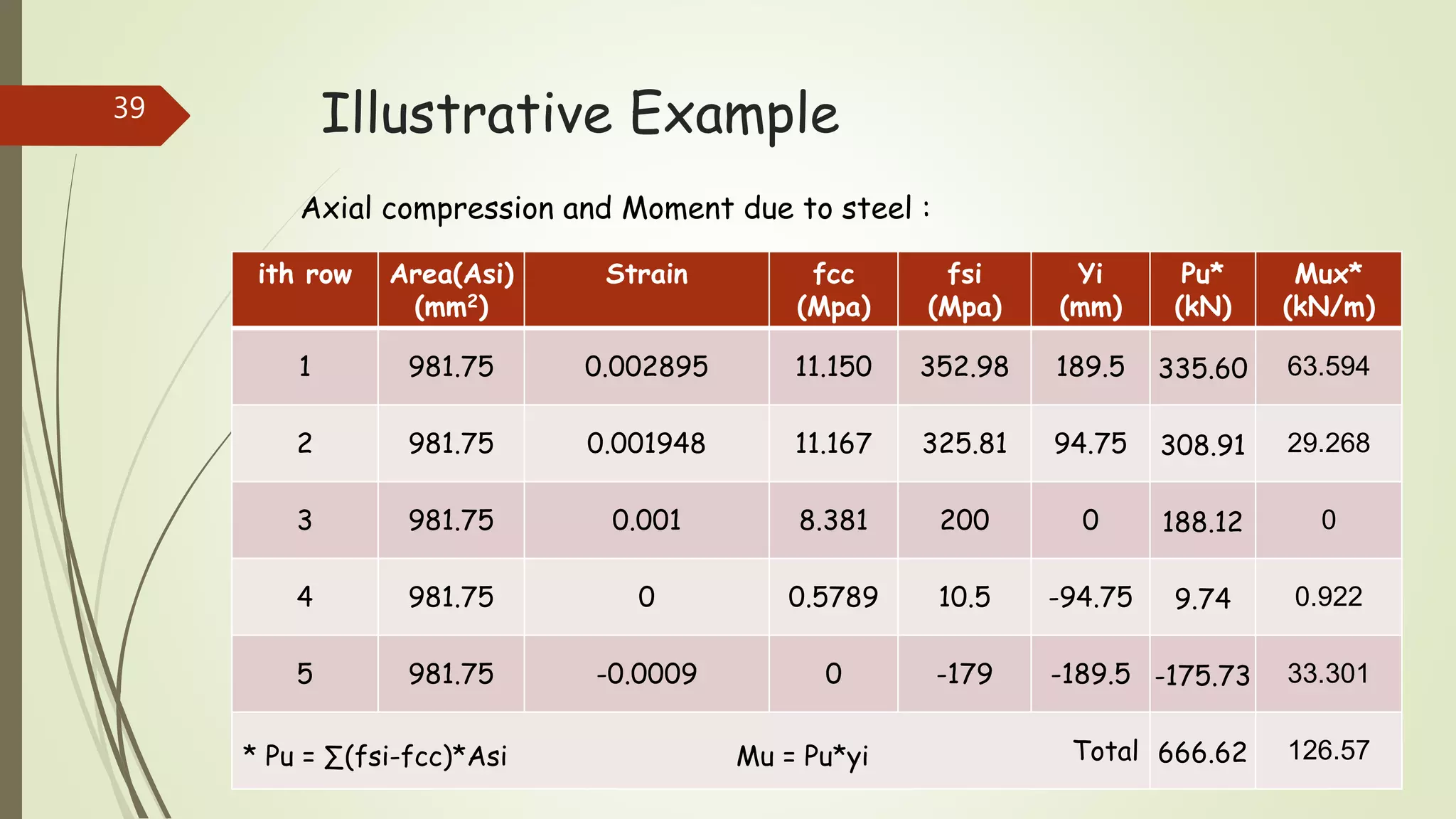

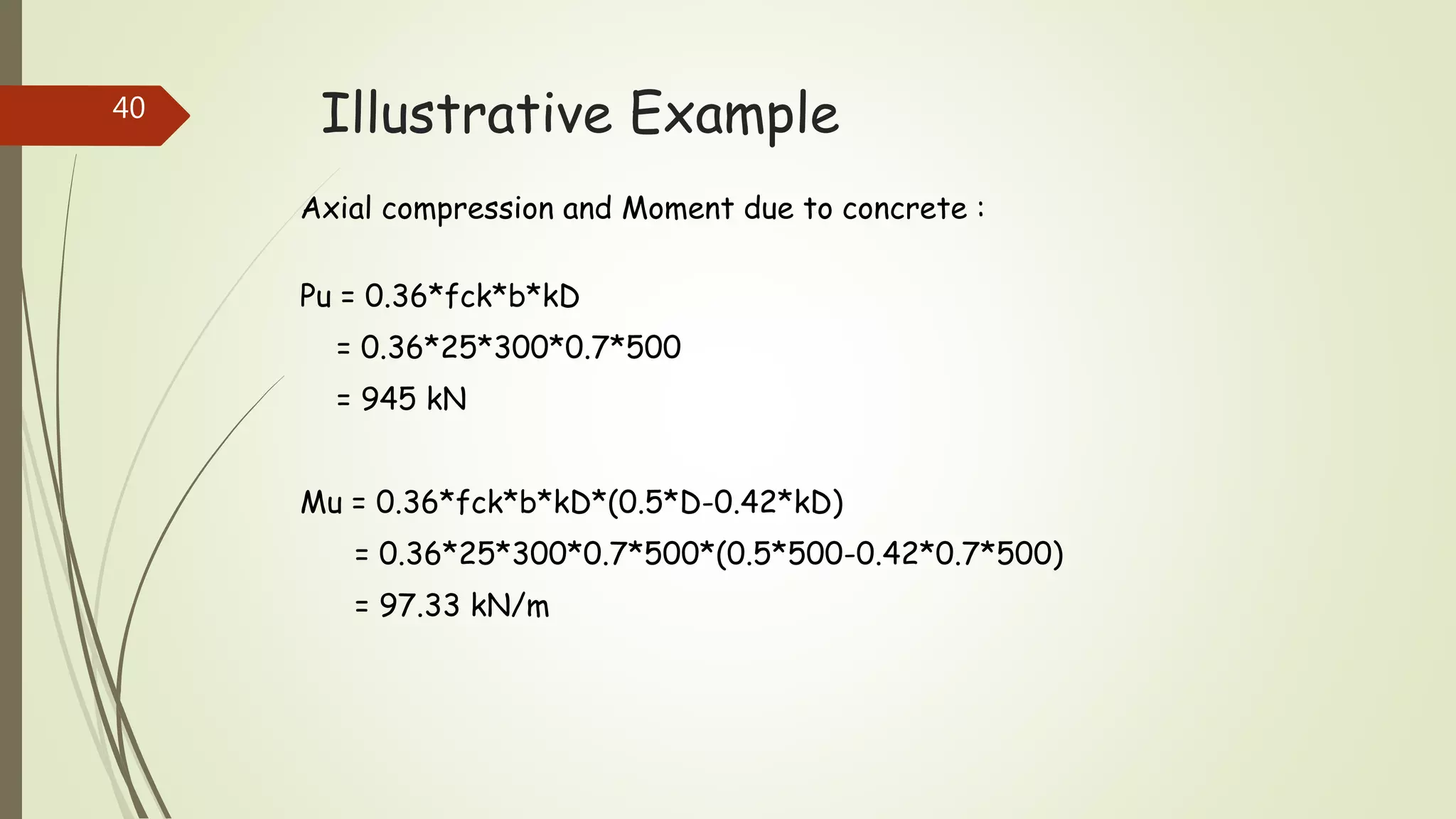

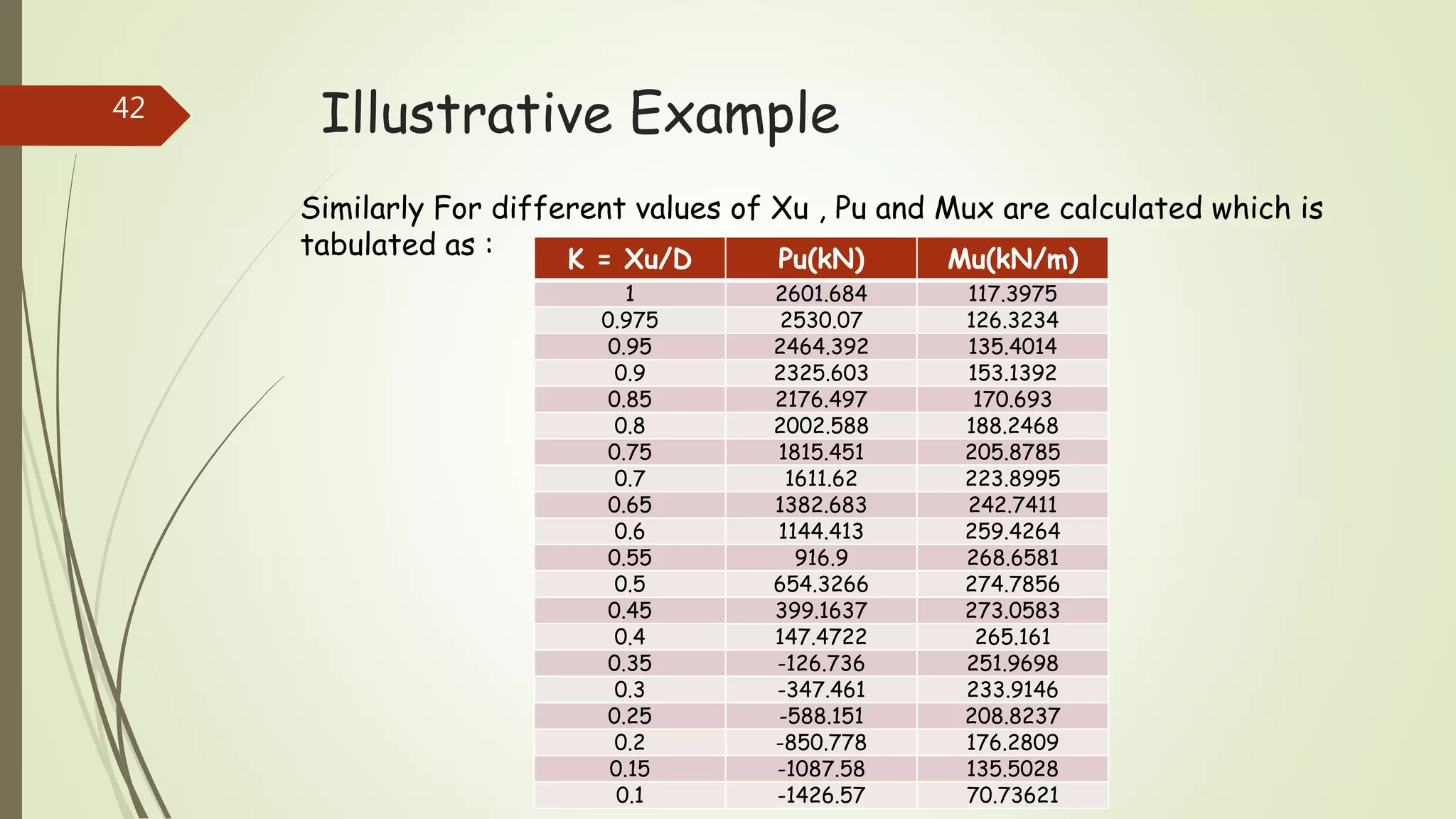

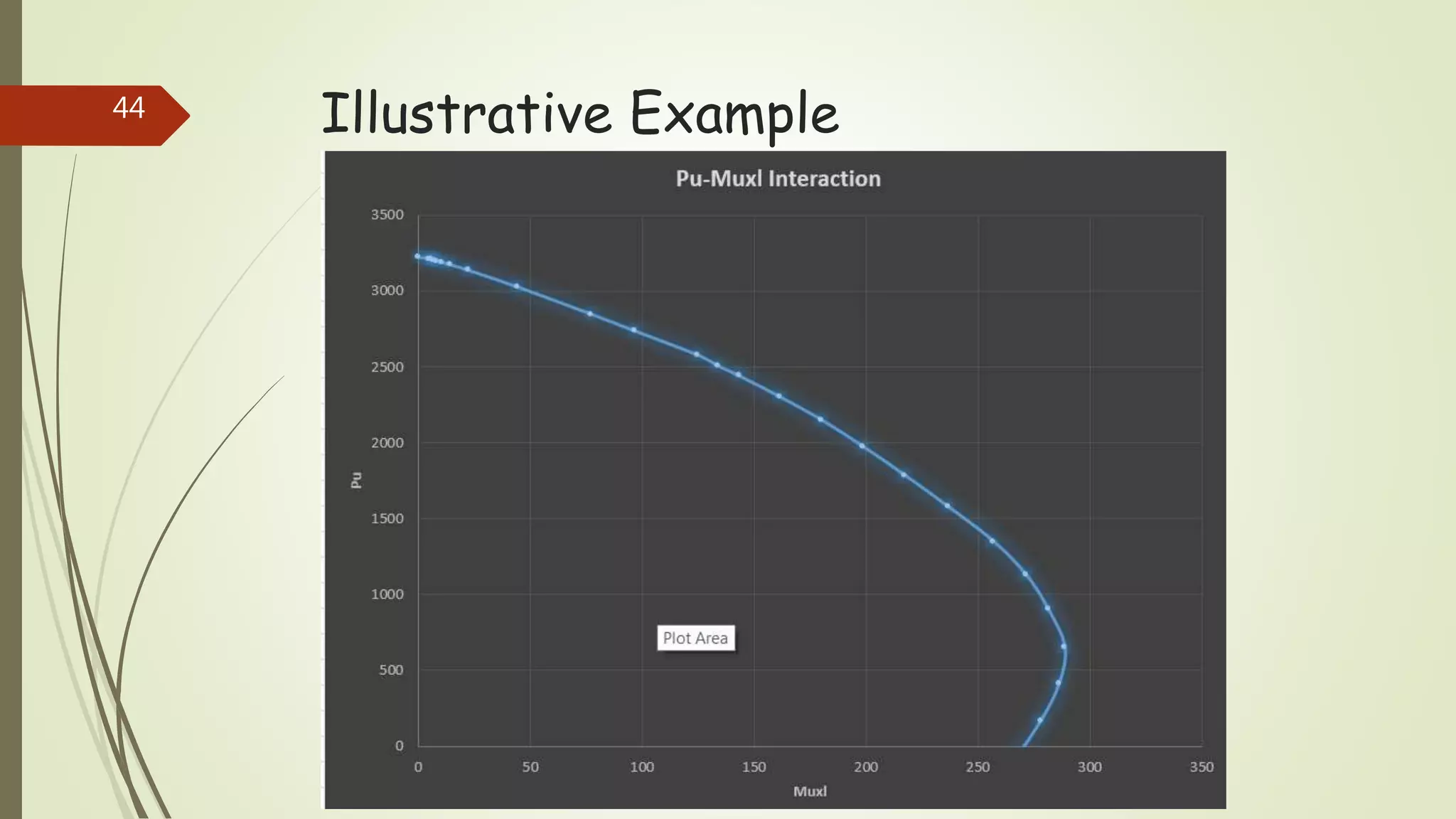

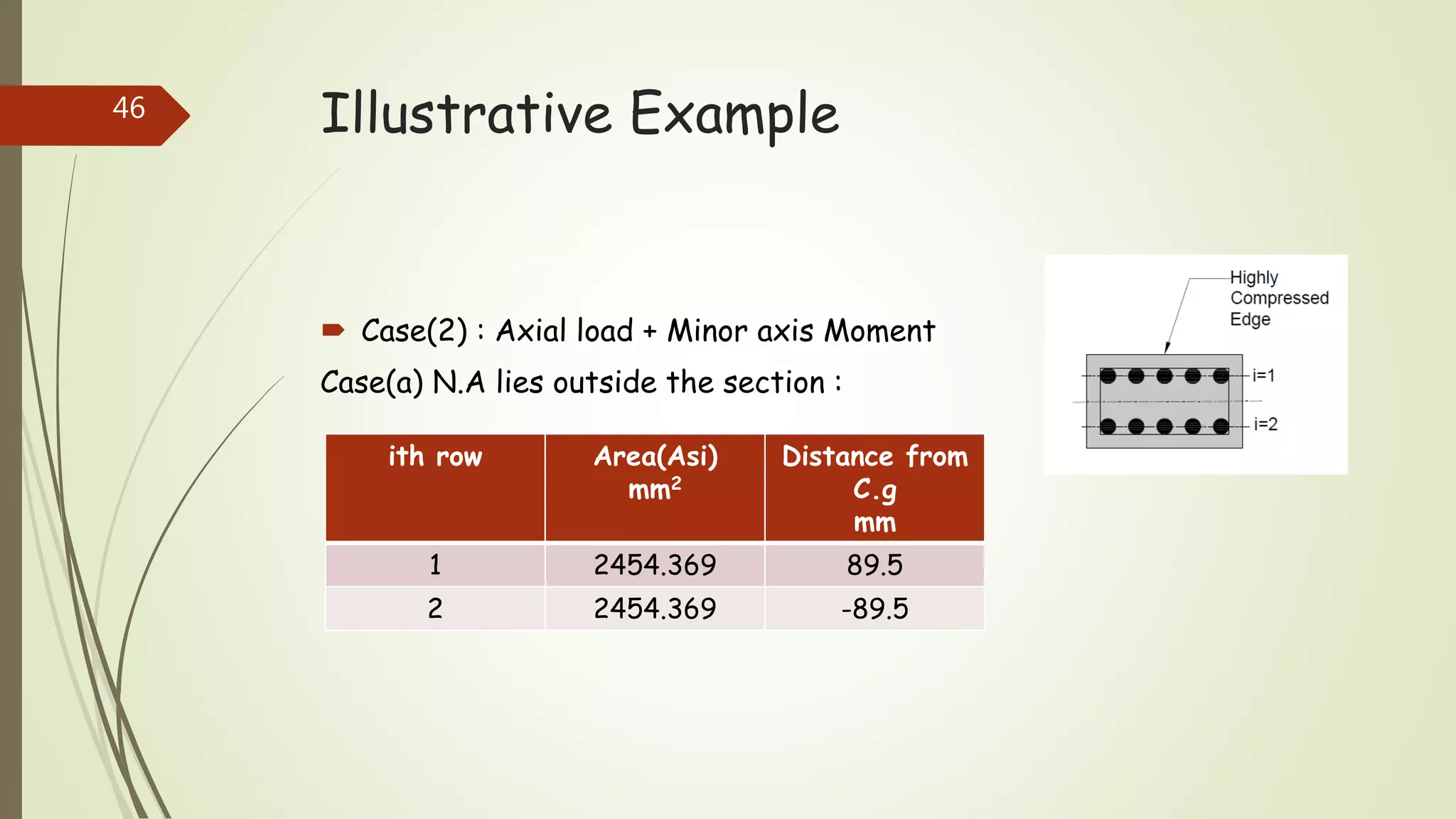

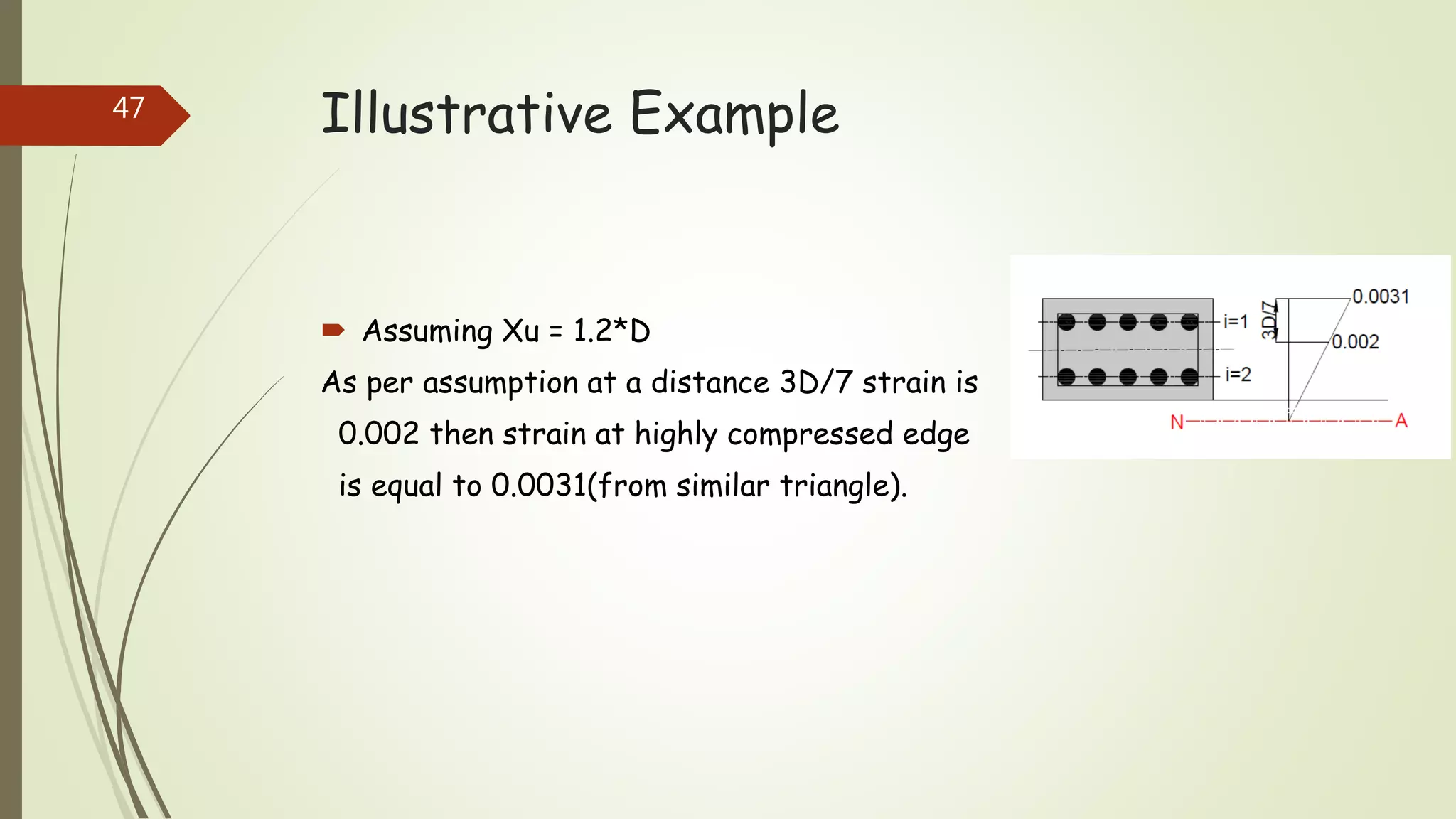

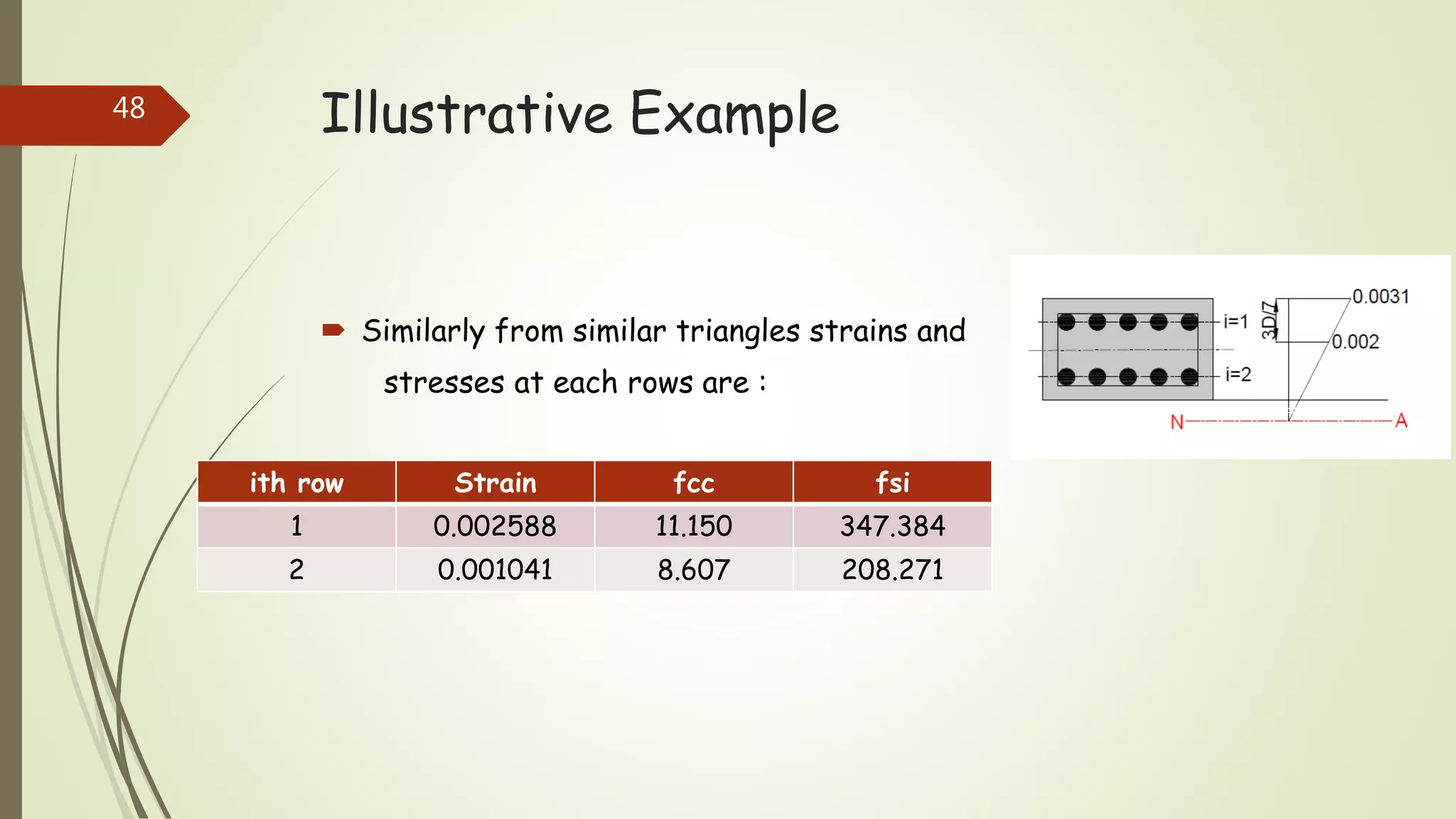

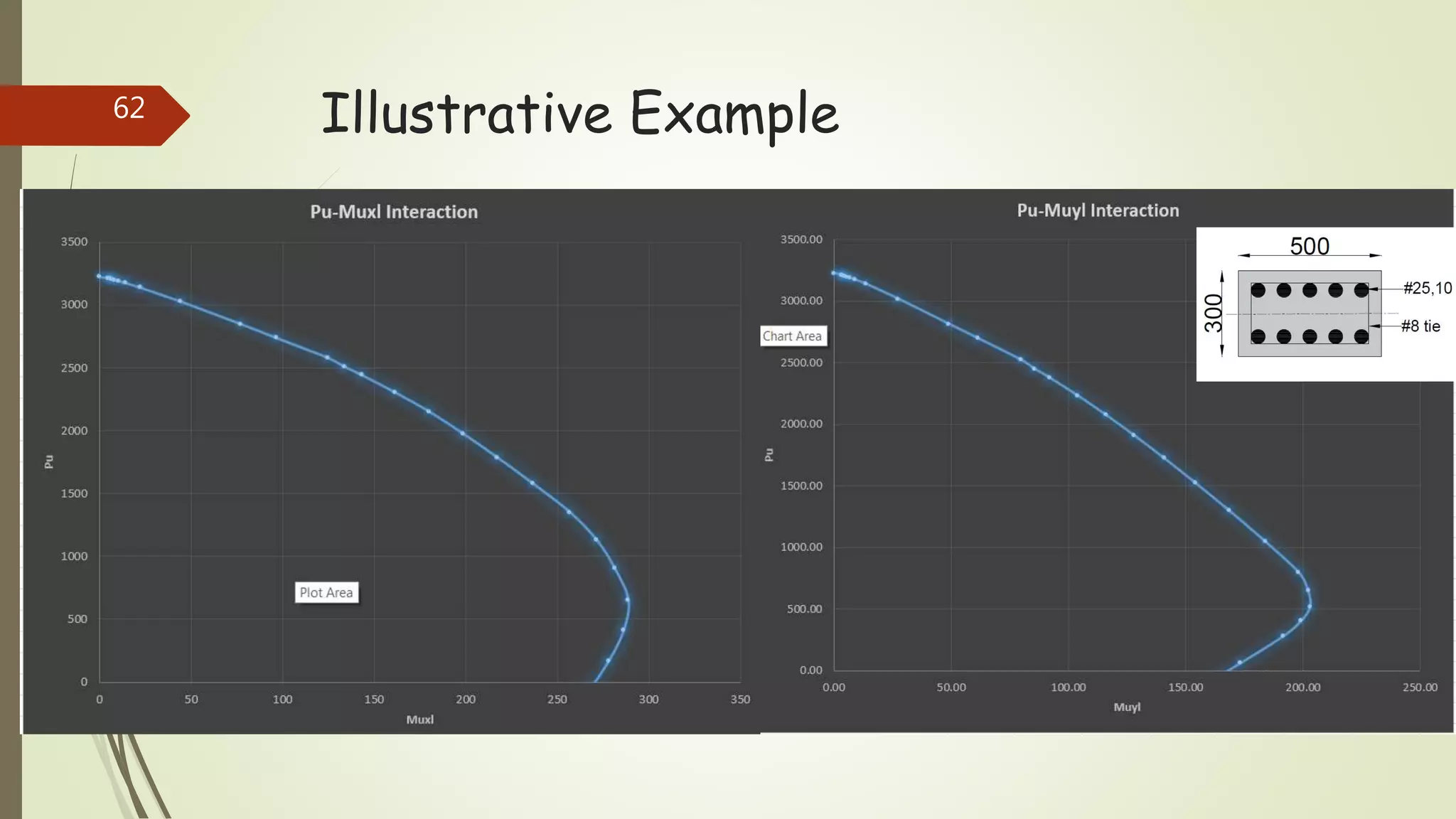

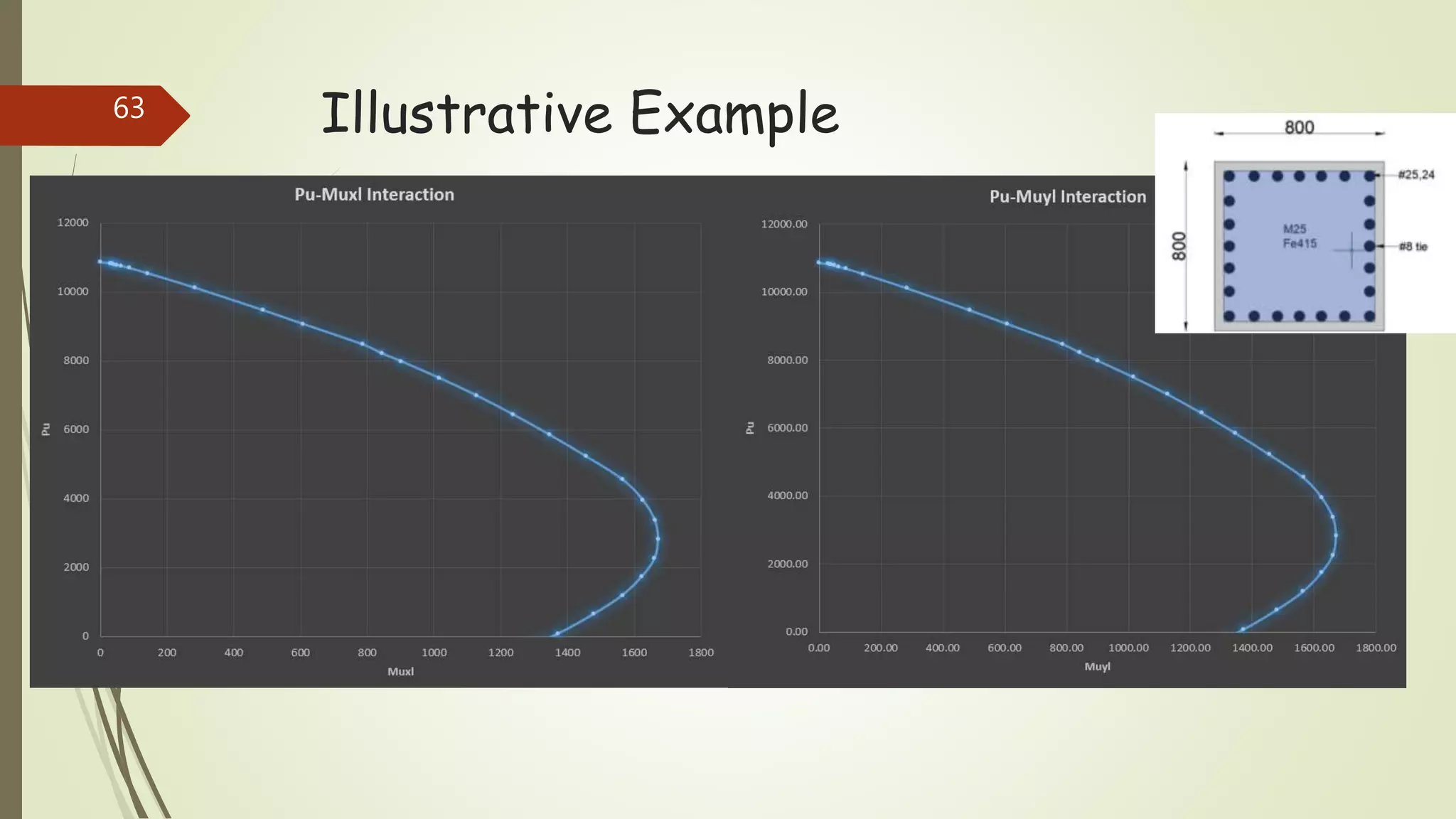

The document provides information on constructing interaction diagrams for reinforced concrete columns. It defines an interaction diagram as a graph showing the relationship between axial load (Pu) and bending moment (Mu) for different failure modes of a column section. The document outlines the design procedure for constructing interaction diagrams, including considering pure axial load, axial load with uniaxial bending, and axial load with biaxial bending. An example is provided to demonstrate constructing the interaction diagram for a given reinforced concrete column cross-section.