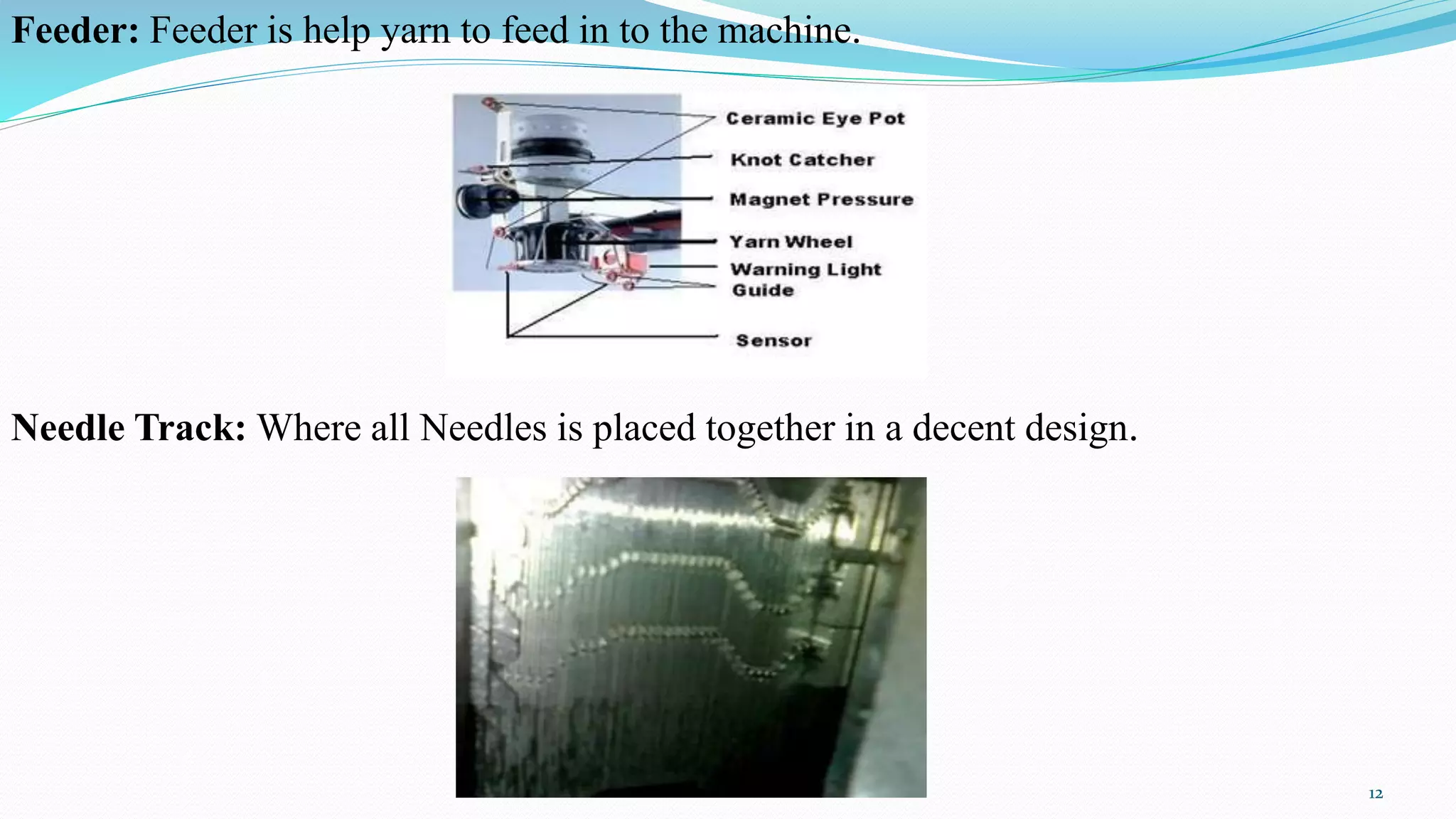

This document discusses the parts and functions of a circular knitting machine. It outlines 23 main parts of the machine including the creel, pulley belt, tension disk, inlet and outlet stop motion, yarn guide, MPF wheel, MPF, feeder ring, disk drum, pattern wheel, feeder, needle track, needle, sinker, sinker ring, cam box, cam, Lycra attachment device, Lycra stop motion, cylinder, cylinder balancer, and air gun nozzle. It provides a brief description of the purpose and function of several key parts like the creel, VDQ pulley, tension disk, MPF, feeder, needle, and sinker. The objective is to understand how