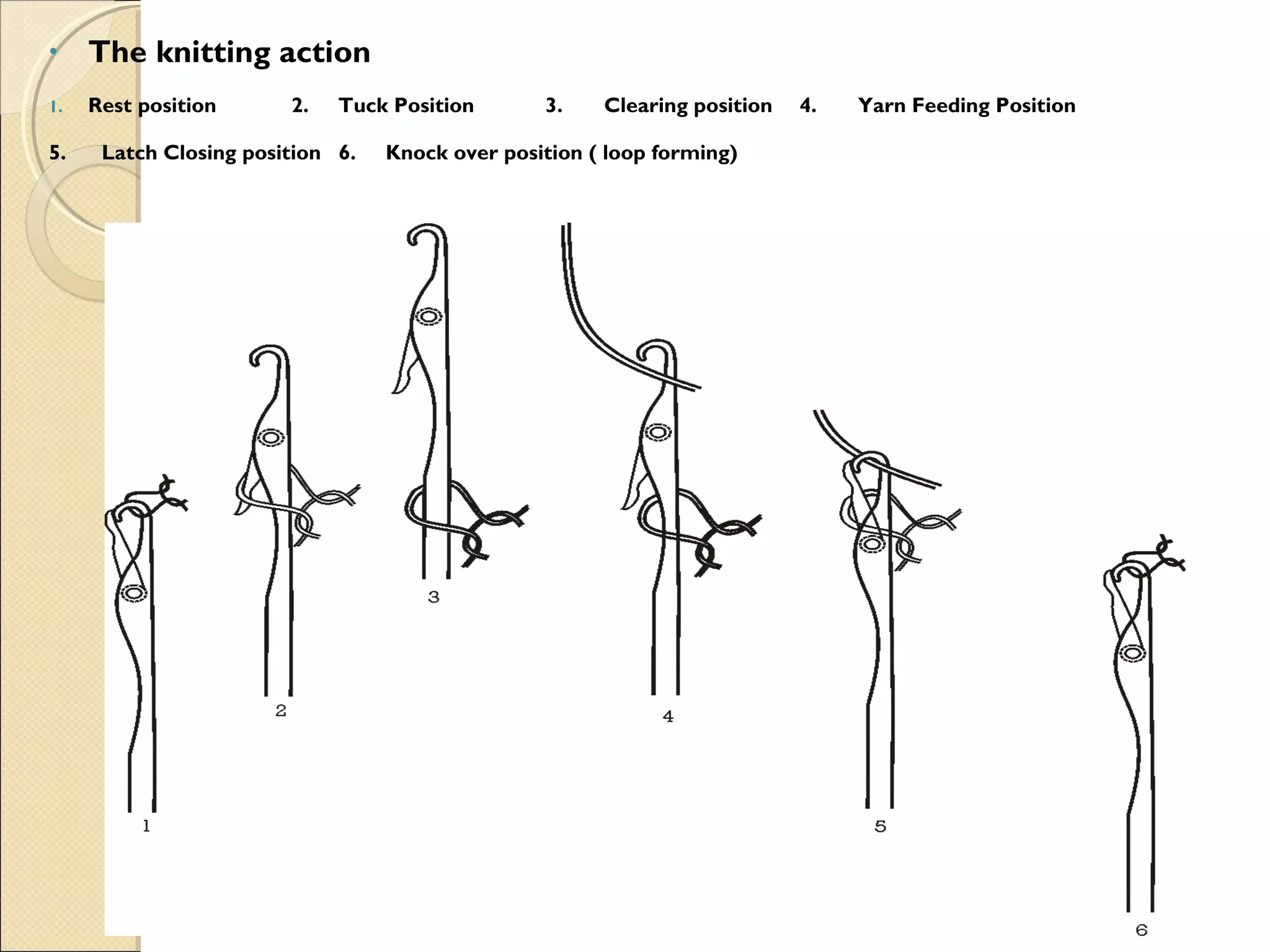

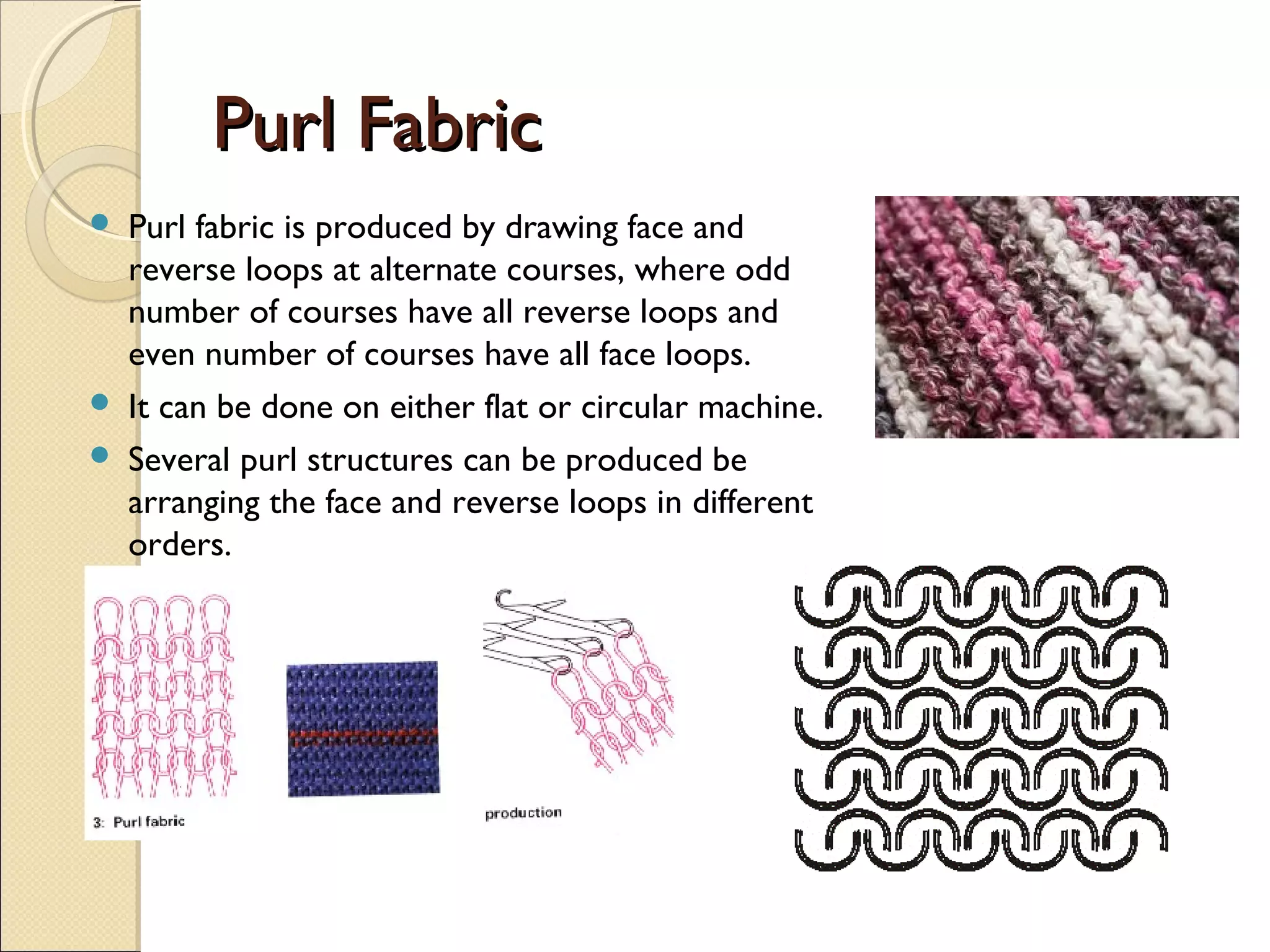

This document discusses different types of weft knitting techniques. It describes the basic process of weft knitting where loops are formed across the width of fabric using a single thread. The main types discussed are plain/single jersey, purl, rib, and interlock fabrics. For each type, it provides details on how they are knitted, their properties and characteristics.