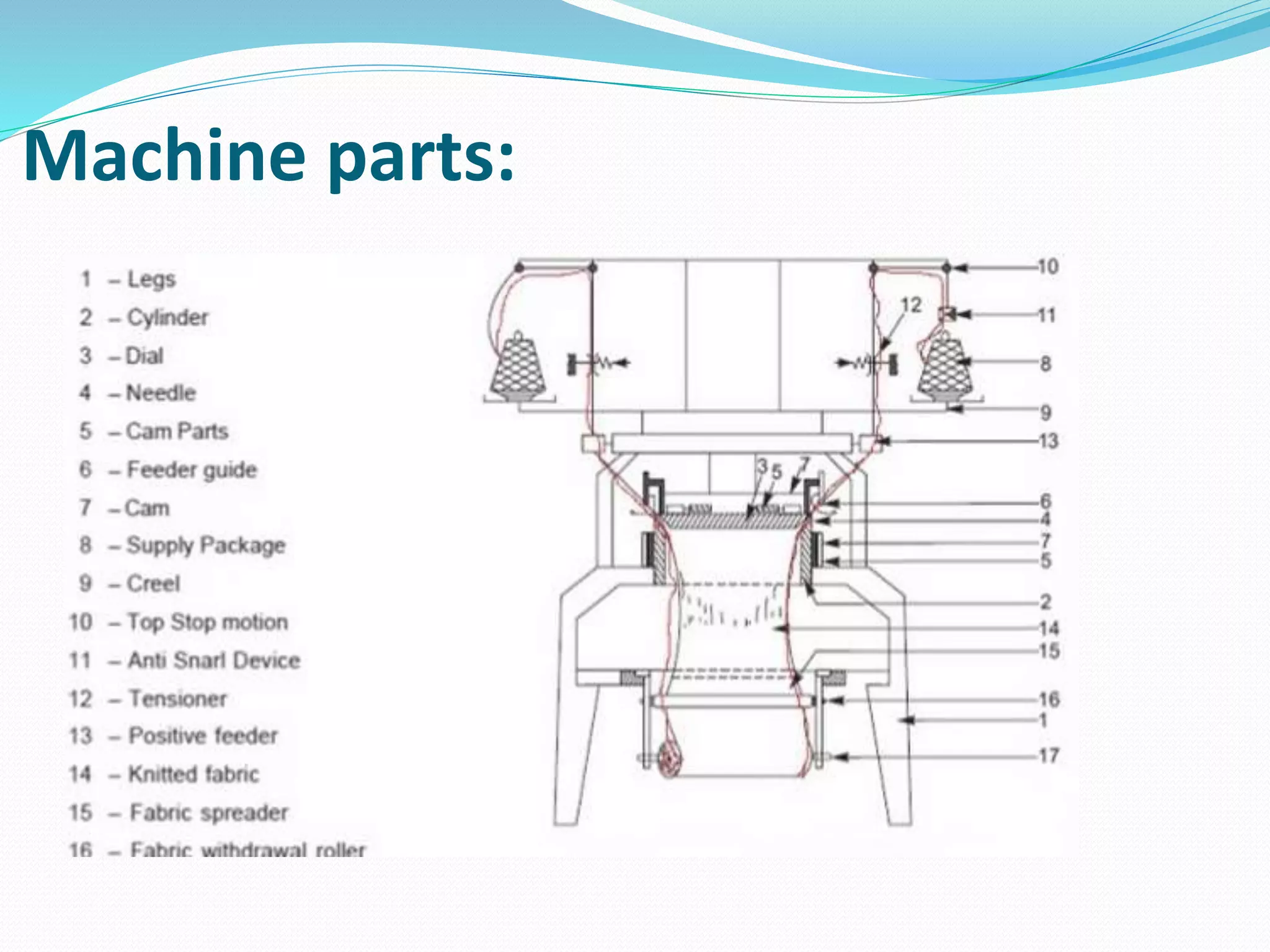

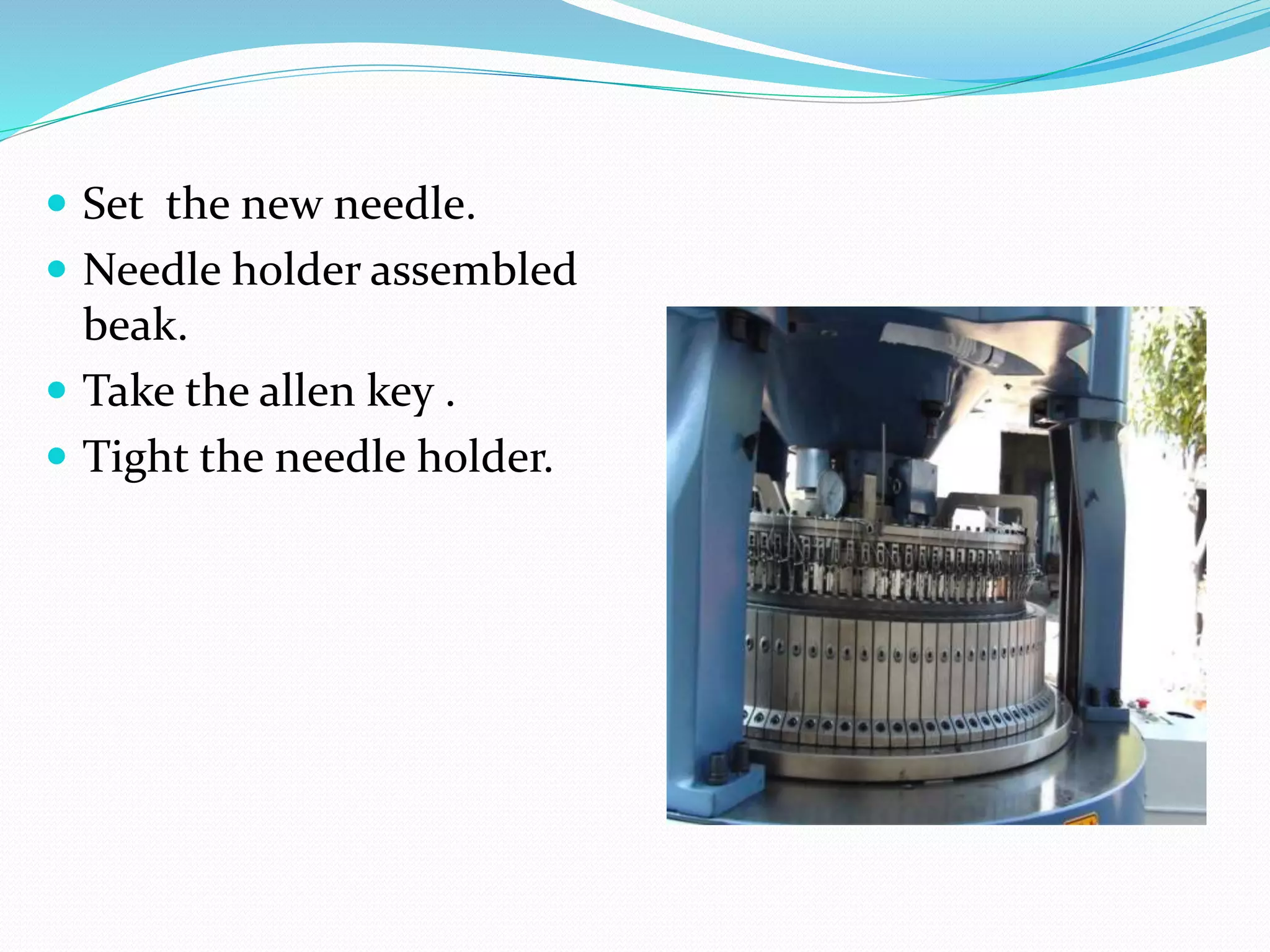

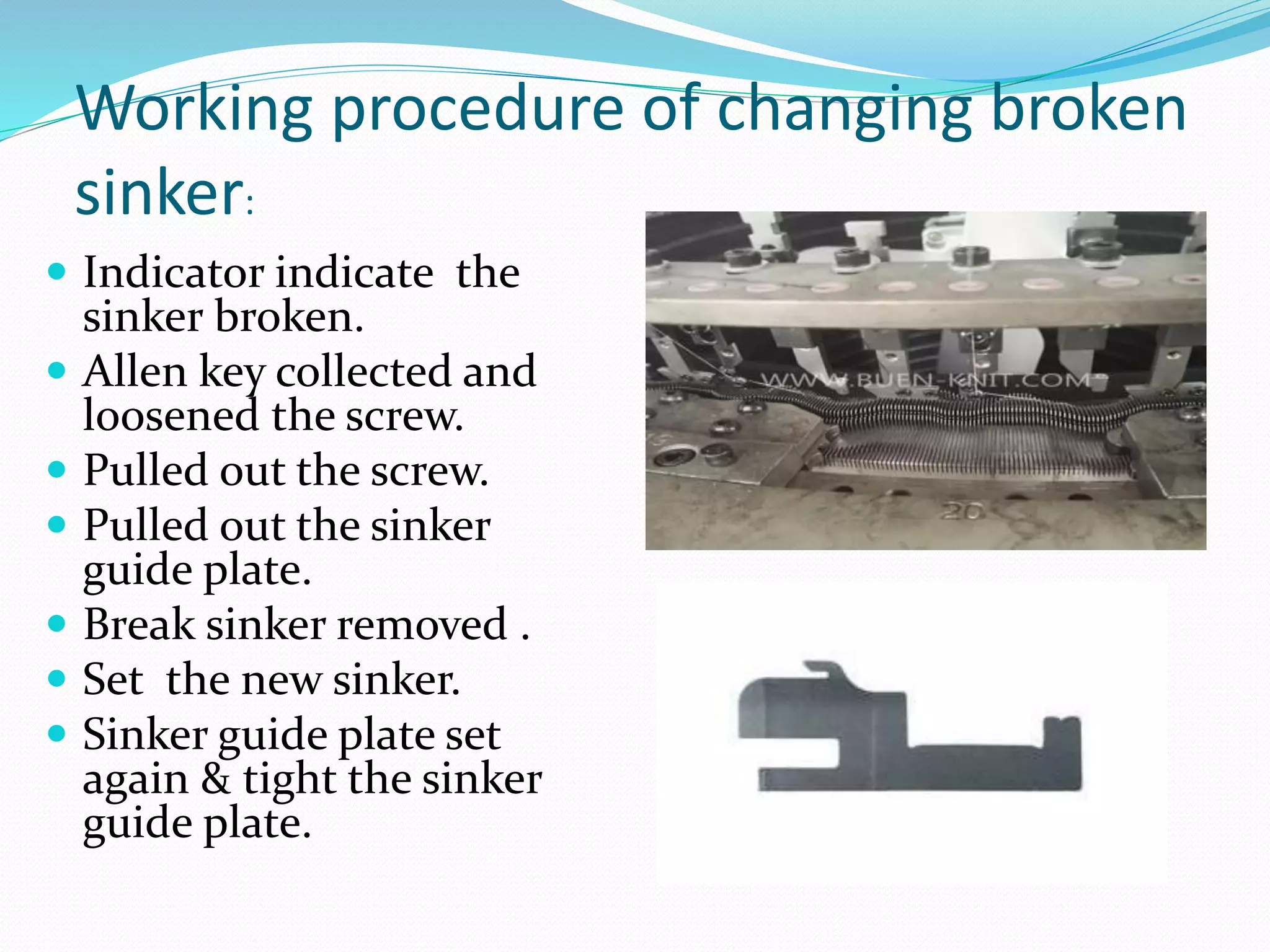

This document describes an experiment on problems and maintenance of a rib circular knitting machine. It introduces the basic elements of the machine: needles, sinkers, and cams. The objectives are to understand how to set up the basic elements, perform maintenance, and understand their functions. It then describes the machine parts and provides step-by-step procedures for replacing broken needles, sinkers, and defective cams. The conclusion states the experiment teaches about problems, maintenance, and specifications of the rib circular knitting machine.