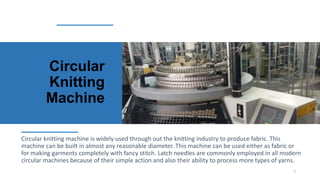

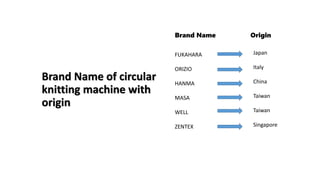

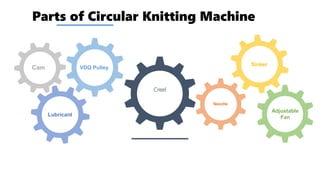

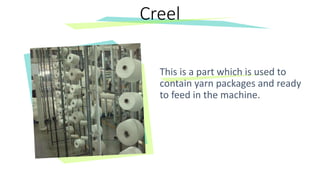

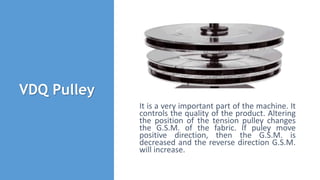

The document summarizes a presentation on circular knitting machines. It discusses the types of knitting machines, listing circular knitting machines as widely used. It provides examples of brand names and origins of circular knitting machines. It then describes the key parts of a circular knitting machine, including the creel, VDQ pulley, cam, needles, sinker, and lubricant. It concludes that knitting and circular knitting machines are important for textile manufacturing.