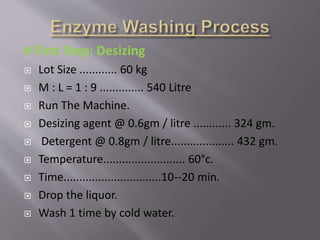

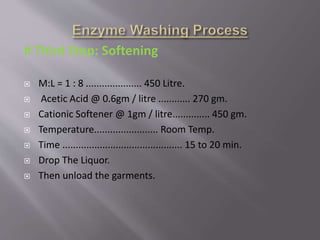

The document discusses the process of enzyme washing of garments. It describes that enzymes are biochemical substances that act as catalysts for specific reactions and can selectively attack substrates. The objectives of enzyme washing are to remove size and starch from garments to make them softer and improve colorfastness. It then outlines the steps of the enzyme washing process which include a desizing step, enzyme wash step using acid or neutral enzymes, a softening step, hydroextractor to remove water, drying, and quality checking before delivery. The enzyme wash helps achieve a smooth surface finish on cellulose fabrics and allows for higher machine loading.