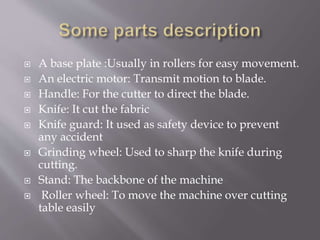

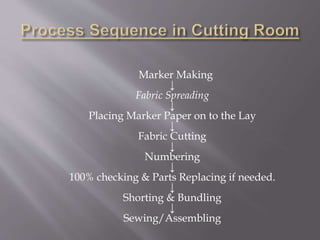

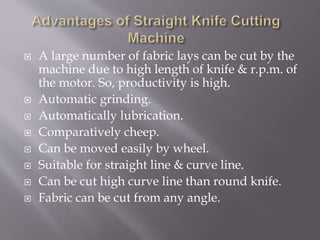

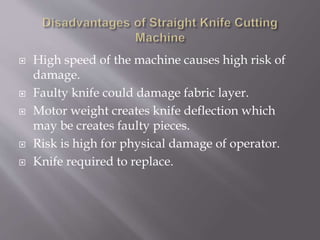

The document discusses a straight knife cutting machine commonly used in garment factories in Bangladesh. It has a motorized blade that cuts fabric according to patterns. The main parts are the base plate, pressure foot, motor stand, sharp belt, pinion shaft, lever, and knife. It can cut a high depth of fabric in a single pass. Proper maintenance, including lubrication and inspection, is important to ensure the long and safe working of the machine. Potential issues include risks of damage from the high-speed blade and motor weight causing knife deflection.