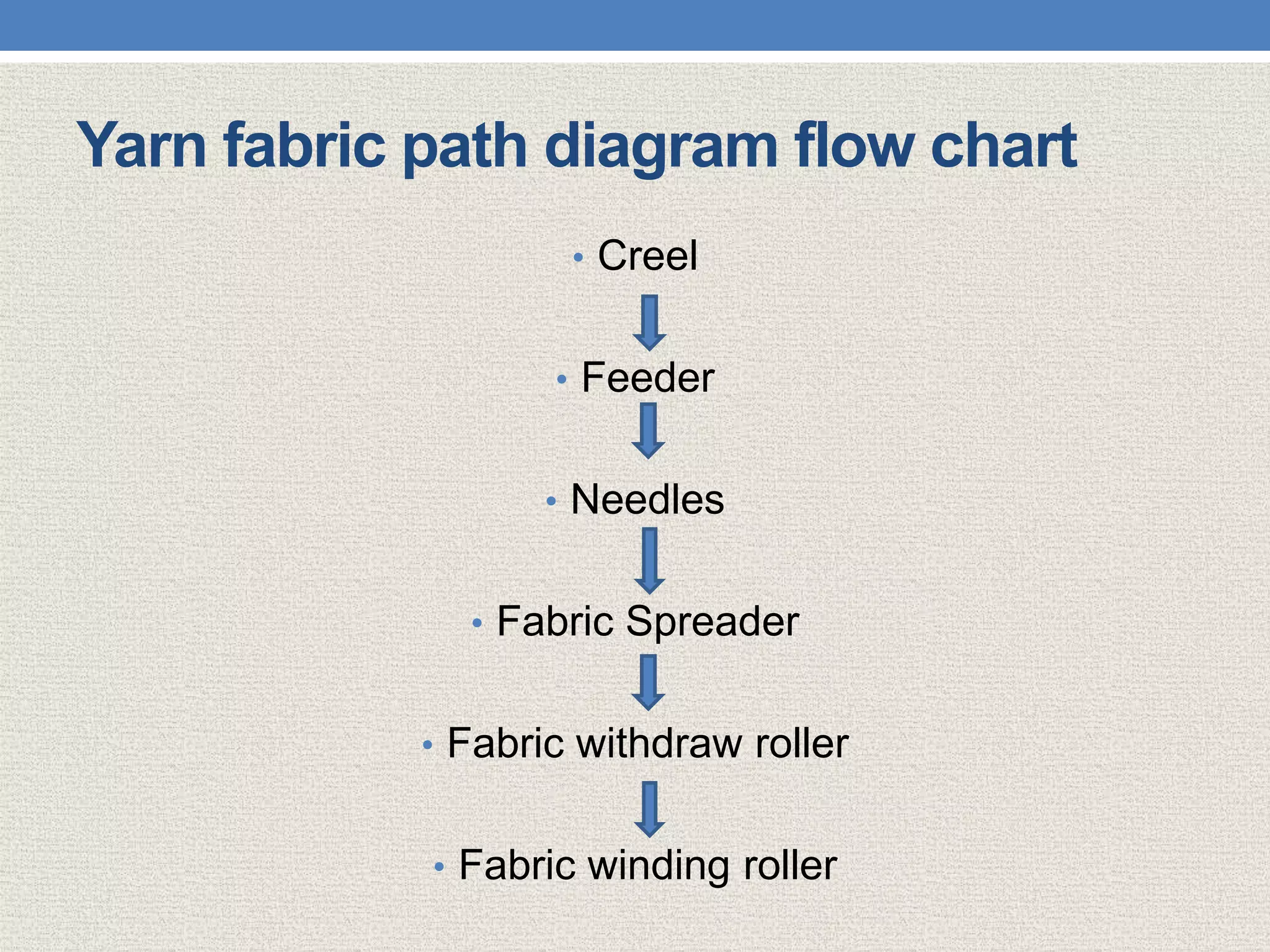

The document summarizes the features and working of a rib circular knitting machine. It describes how rib fabrics have alternating wales of face and back loops which makes the fabric thicker and less prone to curling. It then explains the working of a rib circular knitting machine, including the path of the yarn from creel to needles to fabric winding roller. The key parts of the machine like dial, cylinder, needles and their functions are outlined. Finally, the 8 step knitting action is illustrated with diagrams showing the movement of needles from tuck to cast on position to form loops and stitches.