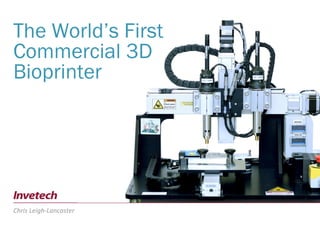

The document describes Invetech's NovoGen MMX Bioprinter, which is the world's first commercial 3D bioprinter. It can print layers of cell aggregates and biogel to construct tissues and blood vessels. The bioprinter has high precision motion axes and dual print heads to print both biogel and cells. It also has thermal control of the biogel and automated cartridge loading. The bioprinter reduces the time needed for blood vessel printing from over 8 hours previously to less than an hour. It provides precise printing down to 20 microns and uses laser calibration and closed-loop motor control. Examples are given of tissues and applications printed so far, ranging from liver tissue to cartilage