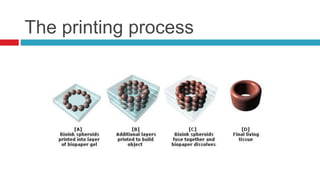

3D bio-printing is a process that creates tissue-like structures by layer-by-layer deposition of cells on a biocompatible scaffold while preserving cell function. This technology aims to address the organ shortage crisis by enabling the production of personalized organs, utilizing patients' own cells to avoid rejection issues. However, challenges remain in vascularizing printed organs, cost, and ethical concerns surrounding stem cell use.