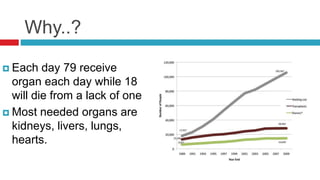

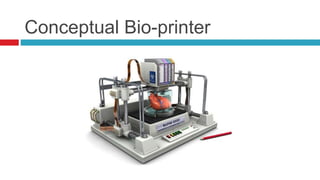

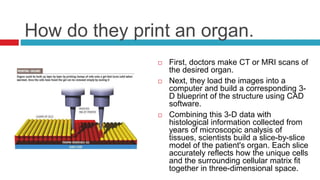

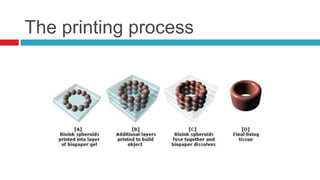

3D bio-printing involves using 3D printers to print biological materials and living cells in a layer-by-layer process to create living tissues and organs. It aims to address the shortage of organs available for transplant by creating organs customized for each patient using their own cells to prevent rejection. While the concept is simple, bio-printing is challenging due to the need to print multiple cell types and keep the cells alive. Researchers are working to modify bio-printers to deposit cells and nurturing gels accurately according to 3D models of organs in order to eventually print transplantable tissues and organs.