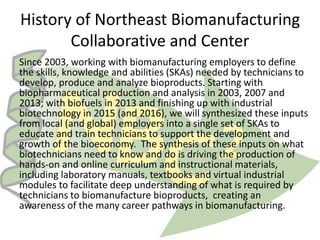

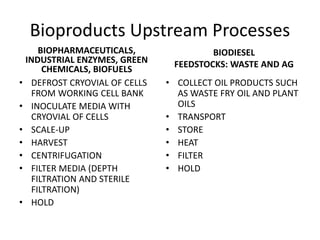

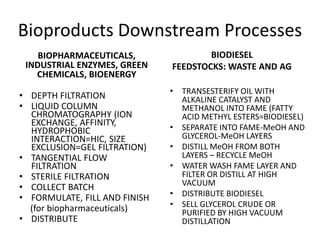

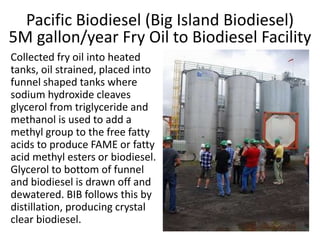

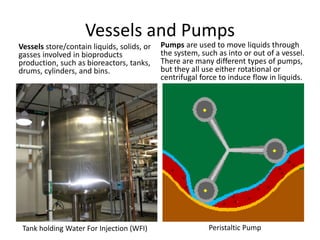

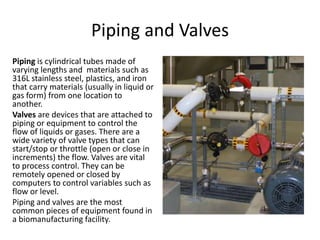

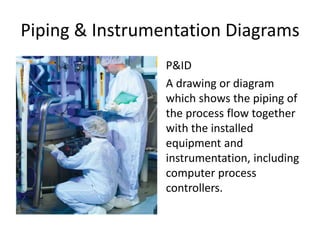

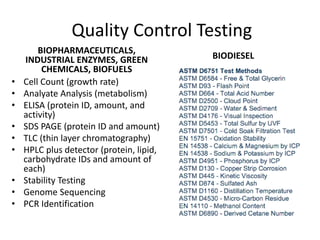

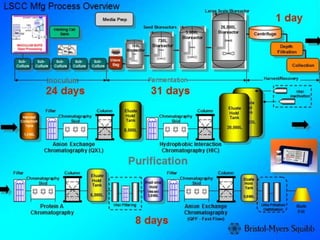

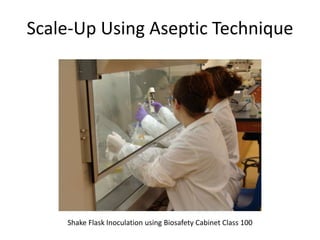

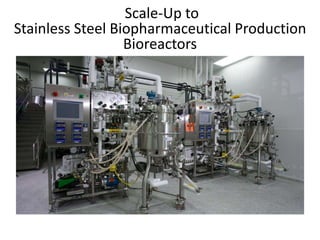

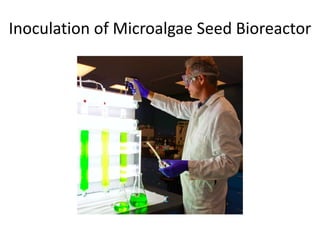

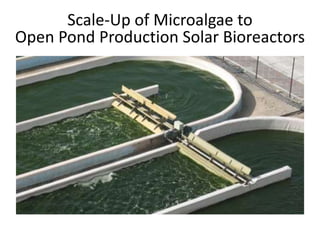

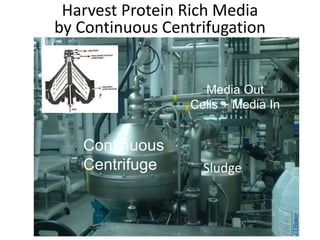

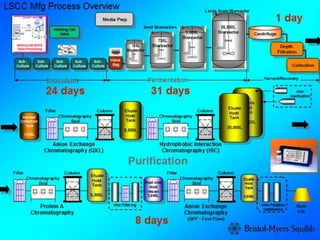

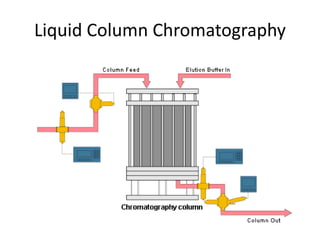

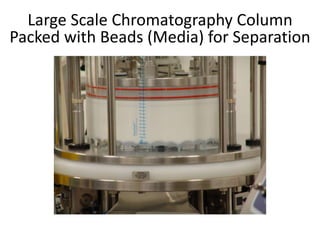

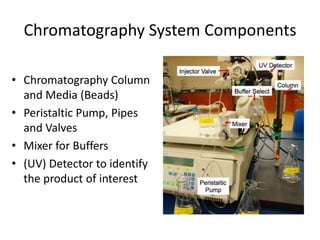

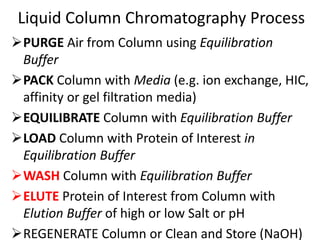

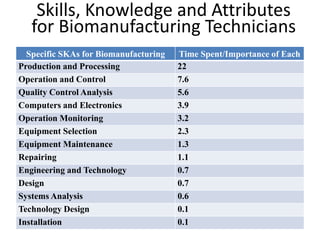

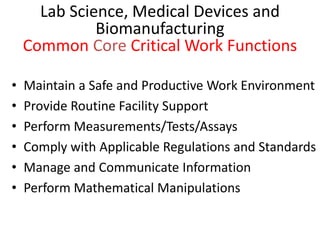

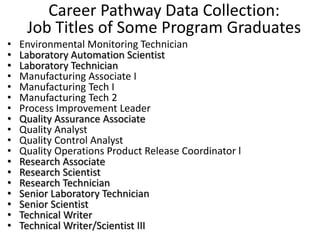

The document provides information about biomanufacturing education and training programs. It discusses the Northeast Biomanufacturing Collaborative and Center's work since 2003 to define the skills, knowledge, and abilities needed by biomanufacturing technicians. It highlights the development of curriculum and instructional materials to educate technicians for careers supporting the bioeconomy. Examples are given of various biomanufacturing processes and the equipment involved in areas like biopharmaceuticals, biofuels, and industrial biotechnology.