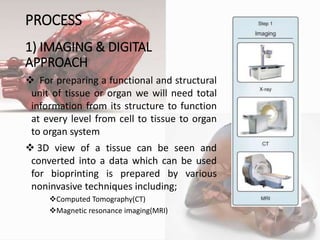

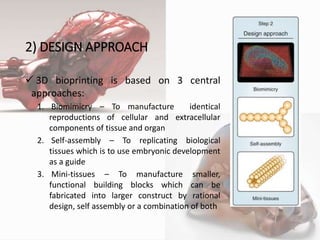

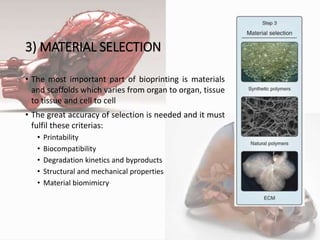

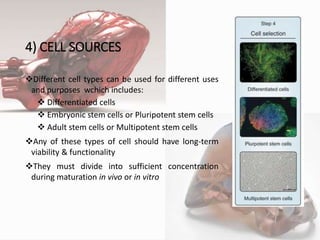

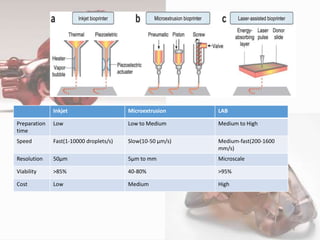

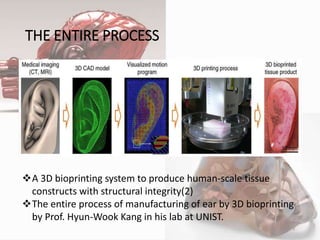

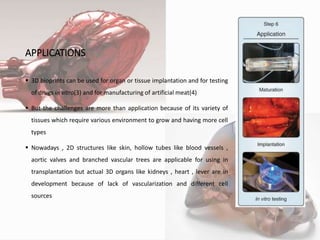

3D bioprinting is a technique that uses 3D printing technologies to precisely position biological materials, cells, and biochemicals in layers to fabricate 3D structures and tissues. The process involves imaging tissues to create digital models, selecting appropriate biomaterials, cell sources, and a bioprinting method (inkjet, microextrusion, or laser). Applications include producing skin, blood vessels, and other tissues for implantation and drug testing. However, fully functional 3D printed organs are still in development due to challenges with vascularization and matching native tissue complexity.