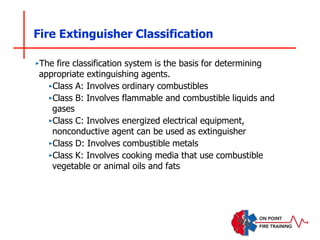

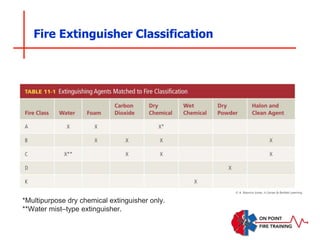

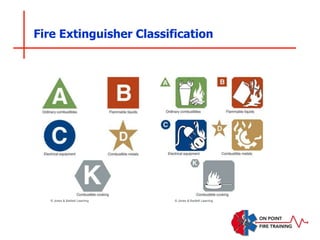

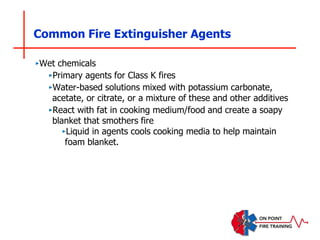

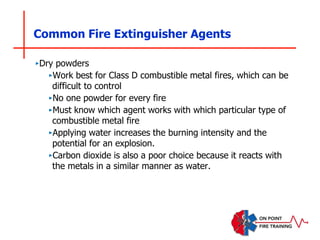

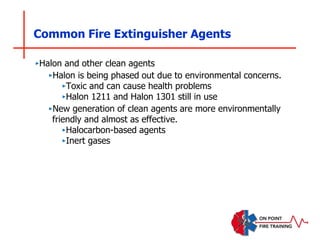

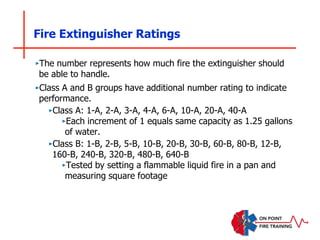

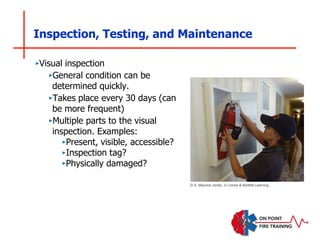

This document discusses portable fire extinguishers, including their classification system based on the type of fire (Class A-K), common extinguishing agents like water, dry chemicals, foam and their applications. It also describes the fire extinguisher rating system, different types of extinguishers like stored pressure and cartridge pressure extinguishers, and the importance of following the PASS method of operation. Regular inspection, testing and maintenance of extinguishers is emphasized to ensure they are in proper working condition.