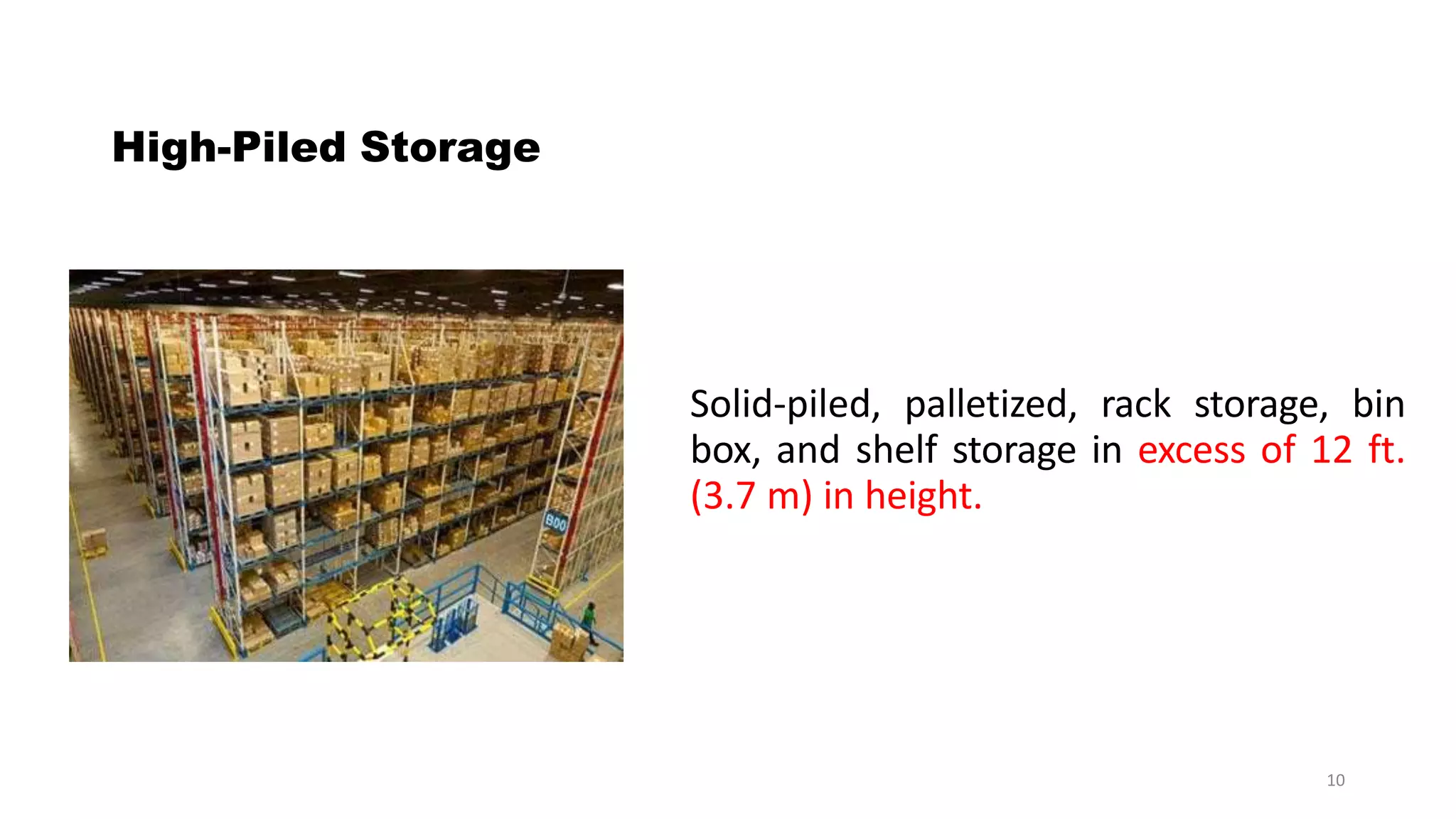

1) Storage occupancies like warehouses present unique fire protection challenges due to factors like flammable goods, dense storage configurations, and high ceilings.

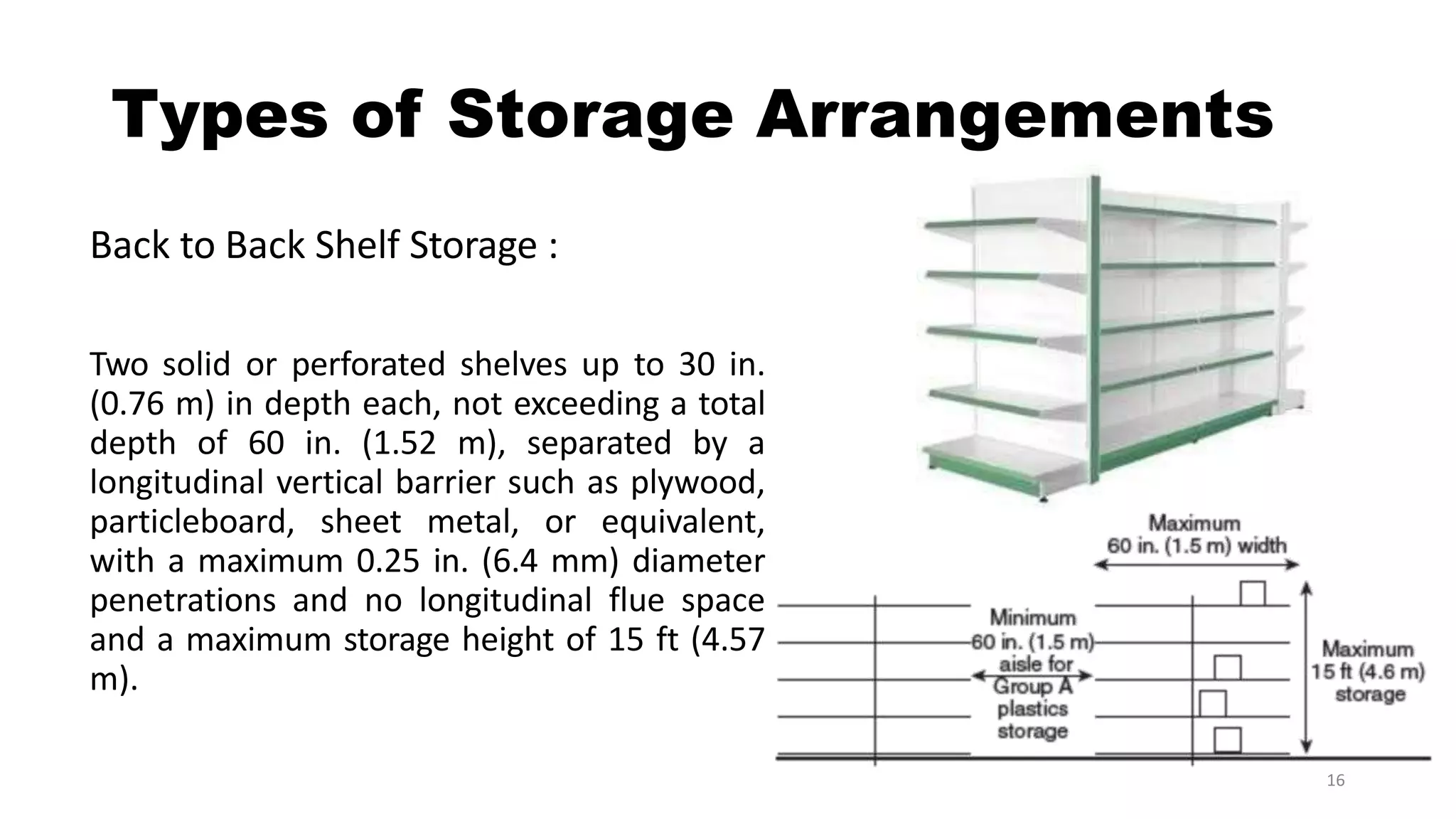

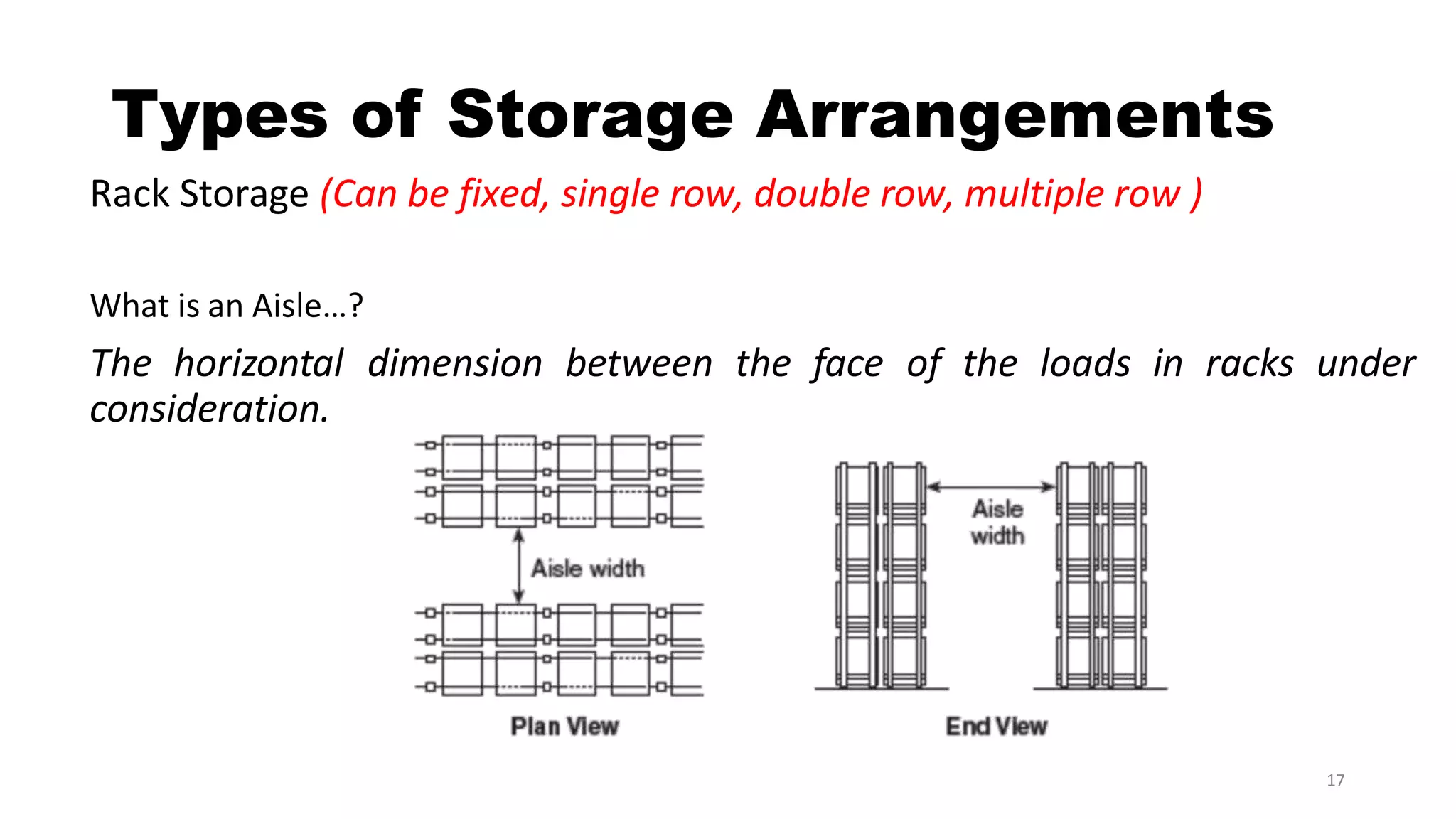

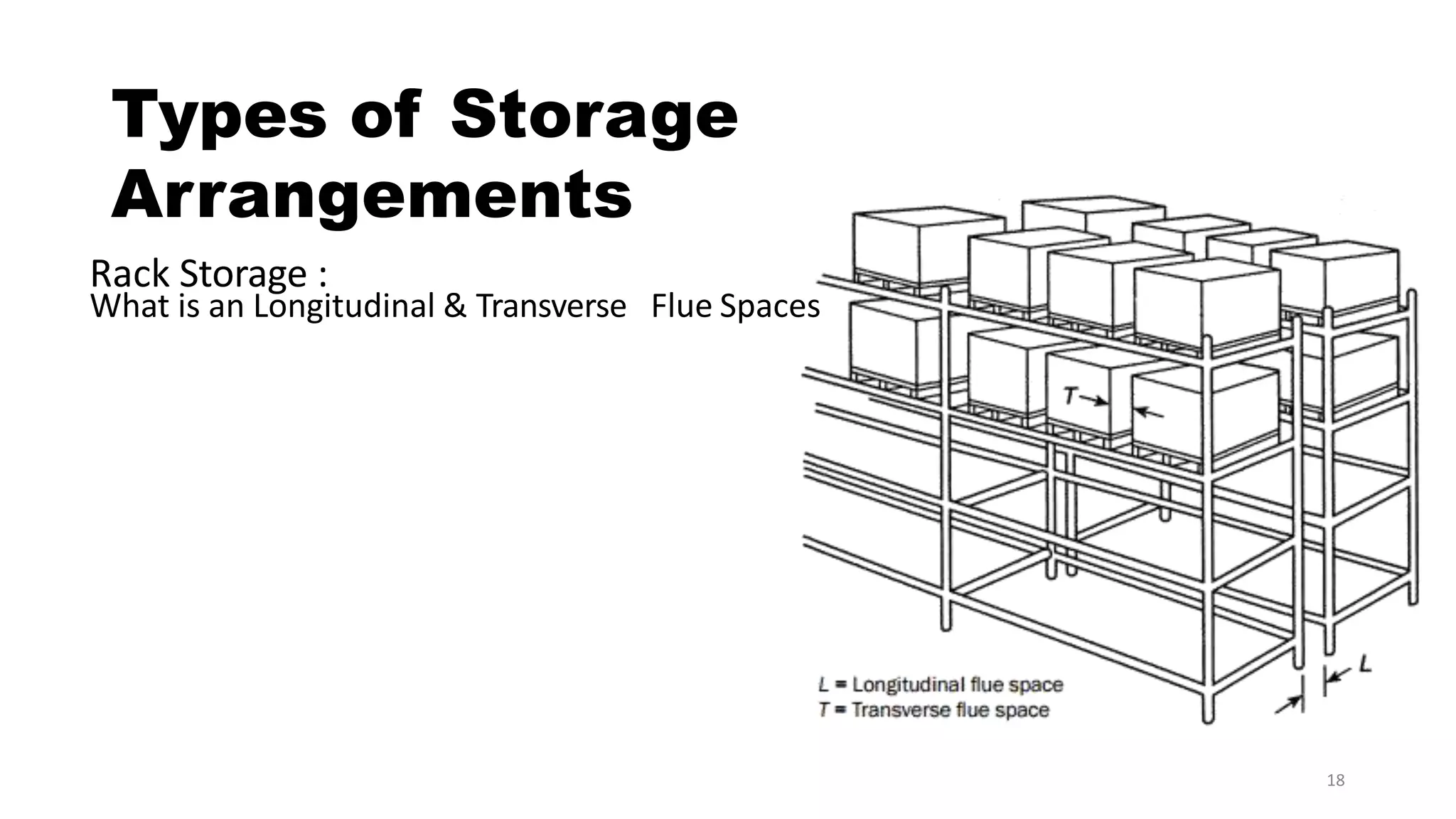

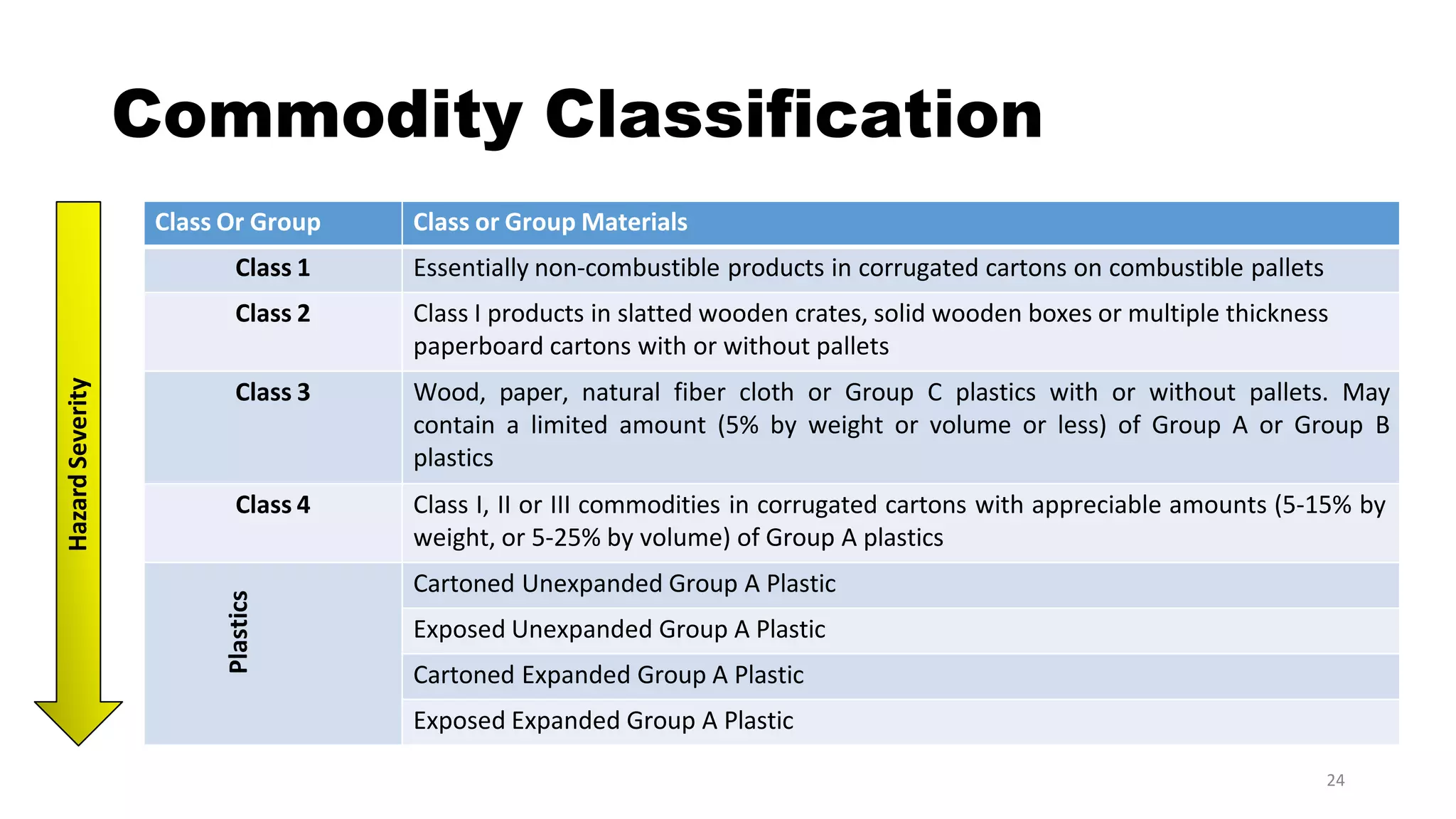

2) Sprinkler systems for storage occupancies must be carefully designed based on considerations like commodity classification, storage arrangement, height, and clearance.

3) NFPA 13 provides guidelines for designing sprinkler systems for different storage setups, ranging from shelving to palletized storage to rack storage. The appropriate sprinkler type, such as CMDA, CMSA, ESFR, or in-rack sprinklers, depends on the specific challenges of the storage occupancy.