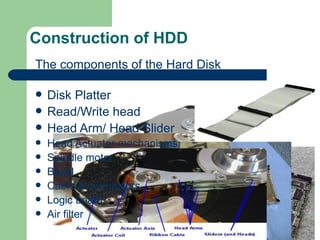

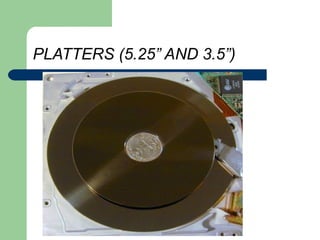

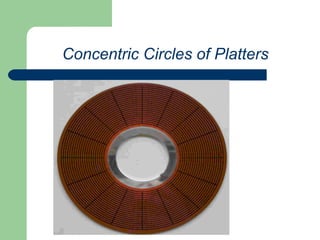

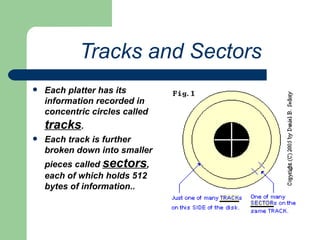

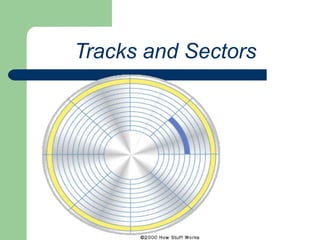

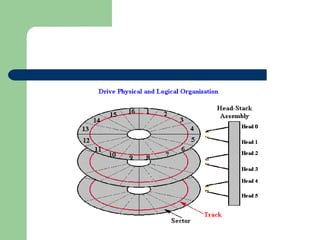

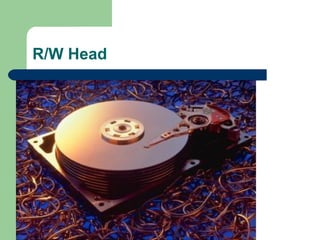

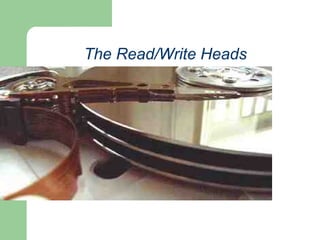

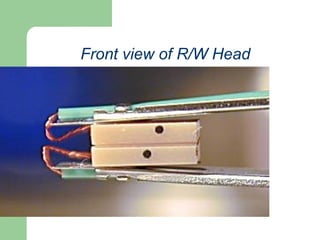

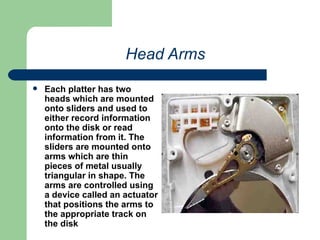

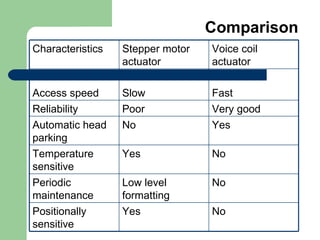

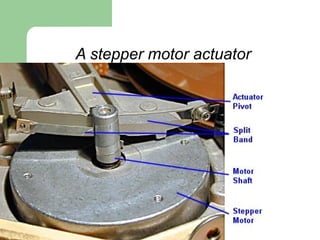

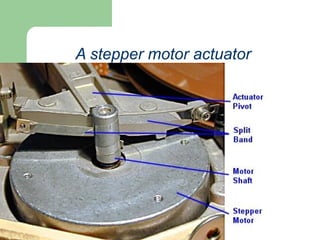

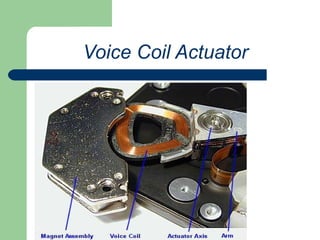

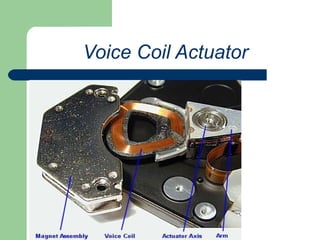

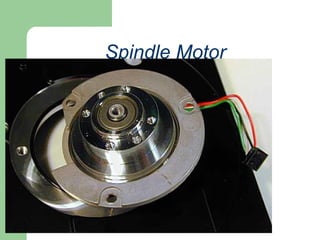

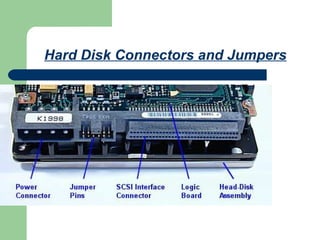

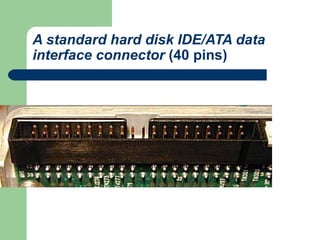

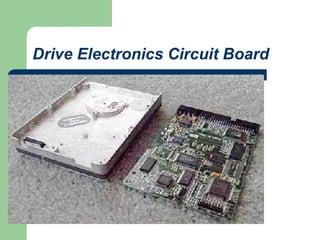

The document summarizes the key components and construction of a hard disk drive (HDD). It describes the main internal components including disk platters coated with magnetic material for data storage, read/write heads that float above the platters, actuator arms that position the heads, and a spindle motor that rapidly spins the platters. It also discusses external sizes, data organization into tracks and sectors, and types of actuators and motors used to control head movement and platter spinning.