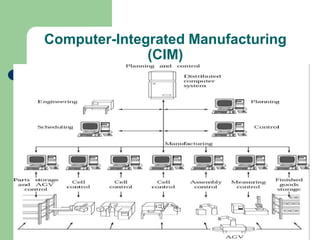

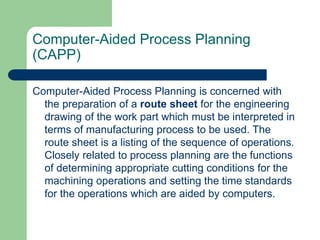

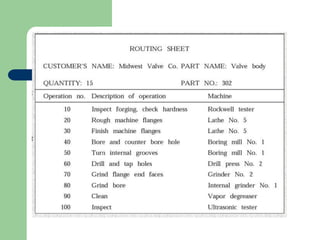

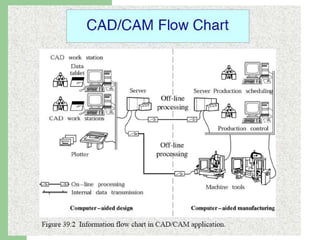

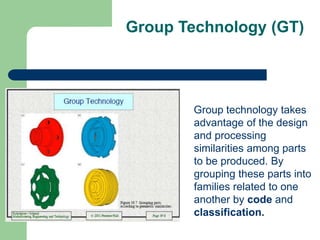

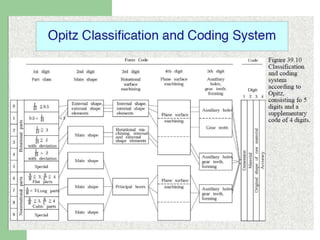

This document discusses how computer-aided manufacturing techniques like computer-aided design, computer-aided engineering, and computer-integrated manufacturing can improve efficiency and quality while reducing costs. It explains that integrating computer systems allows for instant communication between subsystems, better process control, and total quality control. The document also covers topics like computer-aided process planning, simulation, group technology, material requirements planning, and how product design and material selection can optimize a manufacturing process.