Ch03

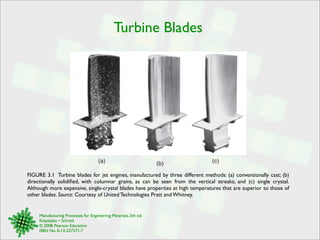

- 1. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Turbine Blades Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 FIGURE 3.1 Turbine blades for jet engines, manufactured by three different methods: (a) conventionally cast; (b) directionally solidified, with columnar grains, as can be seen from the vertical streaks; and (c) single crystal. Although more expensive, single-crystal blades have properties at high temperatures that are superior to those of other blades. Source: Courtesy of United Technologies Pratt and Whitney. (a) (b) (c)

- 2. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Common Crystal Structures FIGURE 3.2 The body-centered cubic (bcc) crystal structure: (a) hard-ball model; (b) unit cell; and (c) single crystal with many unit cells. Common bcc metals include chromium, titanium, and tungsten. Source: After W.G. Moffatt. (a) (b) (c) a a a a a R (a) (b) (c) a a aa a 2R (a) (b) a a c FIGURE 3.3 The face-centered cubic (fcc) crystal structure: (a) hard-ball model; (b) unit cell; and (c) single crystal with many unit cells. Common fcc metals include aluminum, copper, gold and silver.Source: After W.G. Moffatt. FIGURE 3.4 The hexagonal close-packed (hcp) crystal structure: (a) unit cell; and (b) single crystal with many unit cells. Common hcp metals include zinc, magnesium and cobalt. Source: After W.G. Moffatt.

- 3. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Plastic Deformation in Crystals FIGURE 3.5 Permanent deformation of a single crystal under a tensile load.The highlighted grid of atoms emphasizes the motion that occurs within the lattice.(a) Deformation by slip.The b/a ratio influences the magnitude of the shear stress required to cause slip. Note that the slip planes tend to align themselves in the direction of pulling. (b) Deformation by twinning, involving generation of a “twin” around a line of symmetry subjected to shear. Note that the tensile load results in a shear stress in the plane illustrated. (a) (b) Shear stress Slip plane ab Shear stress Twinning plane Atomic planes

- 4. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Shear Stress at Atomic Scale FIGURE 3.6 Variation of shear stress in moving a plane of atoms over another plane. max a b x 1 2 3 4 5 τ = τmax sin 2πx b τmax = G 2π Shear stress: Leads to:

- 5. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Slib Bands in a Single Crystal FIGURE 3.7 Schematic illustration of slip lines and slip bands in a single crystal subjected to a shear stress.A slip band consists of a number of slip planes. The crystal at the center of the upper drawing is an individual grain surrounded by other grains. ~10,000 atomic diameters stress Shear Slip band Slip lines approximately 100 atomic diameters Single crystal (grain) Grain boundaries Approximately 1000 atomic diameters

- 6. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Normal Stress in a Single Crystal FIGURE 3.8 Variation of cohesive stress as a function of distance between a row of atoms. a x Tensile stress Distance between atoms !max " 2 ! ! Work = σmaxλ π σmax = Eγ a ≈ E 10 Work: Leads to:

- 7. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Crystal Defects FIGURE 3.9 Various defects in a single- crystal lattice. Source: After W.G. Moffatt. Vacancy Interstitial impurity atom Substitutional impurity atom Self-interstitial atom (b)(a) Screw dislocation FIGURE 3.10 (a) Edge dislocation, a linear defect at the edge of an extra plane of atoms. (b) Screw dislocation, a helical defect in a three-dimensional lattice of atoms. Screw dislocations are so named because the atomic planes form a spiral ramp.

- 8. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Movement of Edge Dislocation FIGURE 3.11 Movement of an edge dislocation across the crystal lattice under a shear stress. Dislocations help explain why the actual strength of metals is much lower than that predicted by atomic theory. Slip plane

- 9. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Grains During Solidification FIGURE 3.12 Schematic illustration of the various stages during solidification of molten metal. Each small square represents a unit cell. (a) Nucleation of crystals at random sites in the molten metal. Note that the crystallographic orientation of each site is different. (b) and (c) Growth of crystals as solidification continues. (d) Solidified metal, showing individual grains and grain boundaries. Note the different angles at which neighboring grains meet each other. Source: After W. Rosenhain. (c)(b) (d)(a)

- 10. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tensile Stress in Polycrystalline Material FIGURE 3.13 Variation of tensile stress across a plane of polycrystalline metal specimen subjected to tension. Note that the strength exhibited by each grain depends on its orientation. Average stress Stress Tensile stress

- 11. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Grain Sizes TABLE 3.1 Grain sizes. ASTM No. -3 0 3 5 7 9 12 Grains/mm2 1 8 64 256 1,024 4,096 32,800 Grains/mm3 0.7 16 360 2,900 23,000 185,000 4,200,000 ASTM Grain Size Number: Hall-Petch Equation: N = 2n−1 Y = Yi +kd−1/2

- 12. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Embrittlement & Plastic Deformation FIGURE 3.14 Embrittlement of copper by lead and bismuth at 350°C (660°F). Embrittlement has important effects on the strength, ductility, and toughness of materials. Source: After W. Rostoker. Strain 100% Bi Wetting agent 100% Pb 20% Pb -80% Bi 80% Pb -20% Bi Unwetted Stress FIGURE 3.15 Plastic deformation of idealized (equiaxed) grains in a specimen subjected to compression, such as is done in rolling or forging of metals: (a) before deformation; and (b) after deformation. Note the alignment of grain boundaries along a horizontal direction. (b)(a)

- 13. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Crack Due to Bulging FIGURE 3.16 (a) Illustration of a crack in sheet metal subjected to bulging, such as by pushing a steel ball against the sheet. Note the orientation of the crack with respect to the rolling direction of the sheet.This material is anisotropic. (b) Aluminum sheet with a crack (vertical dark line at the center) developed in a bulge test. Source: Courtesy of J.S. Kallend, Illinois Institute of Technology. (a) Side view Top view Crack Sheet Rolling direction (b)

- 14. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Recovery, Recrystallization and Grain Growth FIGURE 3.17 Schematic illustration of the effects of recovery, recrystallization, and grain growth on mechanical properties and shape and size of grains. Note the formation of small new grains during recrystallization. Source: After G. Sachs. Strength Ductility Hardness Cold-worked and recovered New grains Temperature Recrystal- lization Recovery Grain growth Grain size Residual stresses Strength, hardness, ductility

- 15. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Recrystallization FIGURE 3.19 The effect of prior cold work on the recrystallized grain size of alpha brass. Below a critical elongation (strain), typically 5%, no recrystallization occurs. Increasing temperature Strengthandhardness Constant reduction Time Strengthandhardness Increasing reduction Constant temperature Time (a) (b) FIGURE 3.18 Variation of strength and hardness with recrystallization temperature, time, and prior cold work. Note that the more a metal is cold worked, the less time it takes to recrystallize, because of the higher stored energy from cold working due to increased dislocation density. 0.4 0.3 0.2 0.1 0 0 10 20 30 40 Recrystallizedgrainsize(mm) Elongation (%)

- 16. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Surface Roughness; Homologous Temperature FIGURE 3.20 Surface roughness on the cylindrical surface of an aluminum specimen subjected to compression. Source: A. Mulc and S. Kalpakjian. TABLE 3.2 Homologous Temperature Ranges for Various Processes. Process T/Tm Cold working < 0.3 Warm working 0.3 to 0.5 Hot working > 0.6

- 17. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Failure FIGURE 3.22 Schematic illustration of the types of fracture in tension: (a) brittle fracture in polycrystalline metals; (b) shear fracture in ductile single crystals (see also Fig. 3.5a); (c) ductile cup-and-cone fracture in polycrystalline metals (see also Fig. 2.2); (d) complete ductile fracture in polycrystalline metals, with 100% reduction of area. Barreling Cracks (a) (b) (c) (d) FIGURE 3.21 Schematic illustration of types of failure in materials: (a) necking and fracture of ductile materials; (b) buckling of ductile materials under a compressive load; (c) fracture of brittle materials in compression; (d) cracking on the barreled surface of ductile materials in compression. (See also Fig. 6.1b) (a) (b) (c) (d)

- 18. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Ductile Fracture Surface FIGURE 3.23 Surface of ductile fracture in low-carbon steel, showing dimples. Fracture is usually initiated at impurities, inclusions, or preexisting voids in the metal. Source: K.- H. Habig and D. Klaffke. Photo courtesy of BAM, Berlin, Germany.

- 19. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Sequence in Necking and Fracture FIGURE 3.24 Sequence of events in necking and fracture of a tensile-test specimen: (a) early stage of necking; (b) small voids begin to form within the necked region; (c) voids coalesce, producing an internal crack; (d) rest of cross-section begins to fail at the periphery by shearing; (e) final fracture surfaces, known as cup-(top fracture surface) and-cone (bottom surface) fracture. Shear Fibrous (a) (b) (c) (d) (e)

- 20. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Effect of Inclusions FIGURE 3.25 Schematic illustration of the deformation of soft and hard inclusions and their effect on void formation in plastic deformation. Note that hard inclusions, because they do not comply with the overall deformation of the ductile matrix, can cause voids. (a) Before deformation (b) After deformation Matrix Inclusion Soft inclusion Hard inclusion Void Strong direction of deformed metal Hard inclusion Voids or Weak direction

- 21. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Transition Temperature & Strain Aging FIGURE 3.26 Schematic illustration of transition temperature. Note the narrow temperature range across which the behavior of the metal undergoes a major transition. Transition temperature Ductility,toughness Temperature FIGURE 3.27 Strain aging and its effect on the shape of the true-stress-true-strain curve for 0.03% C rimmed steel at 60°C (140°F). Source: A.S. Keh and W.C. Leslie. 350 300 250 200 150 100 Truestress(MPa) 0 0.02 0.04 0.06 0.08 0.10 0.12 0.14 50 40 30 20 psix103 True strain, ! 126 hr 4 hr 30 min 15 min i g c h f e b a d

- 22. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Brittle and Intergranular Fracture FIGURE 3.29 Intergranular fracture, at two different magnifications. Grains and grain boundaries are clearly visible in this micrograph. The fracture path is along the grain boundaries. Source: Courtesy of Packer Engineering. FIGURE 3.28 Typical fracture surface of steel that has failed in a brittle manner.The fracture path is transgranular (through the grains). Compare this surface with the ductile fracture surface shown in Fig. 3.23. Source: Courtesy of Packer Engineering.

- 23. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Fracture Mode & Surface FIGURE 3.30 Three modes of fracture. Mode I has been studied extensively, because it is the most commonly observed in engineering structures and components. Mode II is rare. Mode III is the tearing process; examples include opening a pop-top can, tearing a piece of paper, and cutting materials with a pair of scissors. Mode I Mode IIMode III FIGURE 3.31 Typical fatigue fracture surface on metals, showing beach marks. Most components in machines and engines fail by fatigue and not by excessive static loading. Source: Courtesy of Packer Engineering.

- 24. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Fatigue FIGURE 3.32 Reduction in fatigue strength of cast steels subjected to various surface-finishing operations. (a) Effect of surface roughness. Note that the reduction is greater as the surface roughness and strength of the steel increase. Source: After J.E. Shigley and L.D. Mitchell. (b) Effect of residual stress, as developed by shot peening (see Section 4.5.1). Source: After B.J. Hamrock, S.R. Schmid and B.O. Jacobson. 483 414 345 276 207 138 70 60 50 40 30 20 Stressamplitude,S(MPa) ksi 104 105 106 107 108 Number of cycles to failure, N Al 7050-T7651 Ti-6Al-4V Polished (b) Shot peened Machined (a) Reductioninfatiguestrength(%) Ultimate tensile strength (psi x 103) 100 15050 200 500 800 1000 1300 MPa Fine polishing Polishing Grinding Fine turning Rough turning As cast 60 70 50 40 30 20 10 0

- 25. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Physical Properties of Materials Coefficient Thermal of Thermal Density Melting Point Specific Heat Conductivity Expansion (kg/m3) (◦C) (J/kg K) (W/m K) (µm/m◦C) METAL Aluminum 2700 660 900 222 23.6 Aluminum alloys 2630-2820 476-654 880-920 121-239 23.0-23.6 Beryllium 1854 1278 1884 146 8.5 Columbium (niobium) 8580 2468 272 52 7.1 Copper 8970 1082 385 393 16.5 Copper alloys 7470-8940 885-1260 337-435 29-234 16.5-20 Gold 19300 1063 129 317 19.3 Iron 7860 1537 460 74 11.5 Steels 6920-9130 1371-1532 448-502 15-52 11.7-17.3 Lead 11,350 327 130 35 29.4 Lead alloys 8850-11,350 182-326 126-188 24-46 27.1-31.1 Magnesium 1745 650 1025 154 26.0 Magnesium alloys 1770-1780 610-621 1046 75-138 26.0 Molybdenum alloys 10,210 2610 276 142 5.1 Nickel 8910 1453 440 92 13.3 Nickel alloys 7750-8850 1110-1454 381-544 12-63 12.7-18.4 Silicon 2330 1423 712 148 7.63 Silver 10,500 961 235 429 19.3 Tantalum alloys 16,600 2996 142 54 6.5 Titanium 4510 1668 519 17 8.35 Titanium alloys 4430-4700 1549-1649 502-544 8-12 8.1-9.5 Tungsten 19,290 3410 138 166 4.5 NONMETALLIC Ceramics 2300-5500 — 750-950 10-17 5.5-13.5 Glasses 2400-2700 580-1540 500-850 0.6-1.7 4.6-70 Graphite 1900-2200 — 840 5-10 7.86 Plastics 900-2000 110-330 1000-2000 0.1-0.4 72-200 Wood 400-700 — 2400-2800 0.1-0.4 2-60 TABLE 3.3 Physical Properties of Various Materials at Room Temperature.

- 26. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Effect of Carbon on Steel Properties FIGURE 3.33 Effect of carbon content on the mechanical properties of carbon steel. Tensile strength Yield strength 1000 800 600 400 200 Impact energy % elongation 0 Yieldandtensilestrength(MPa) 0 0.2 0.4 0.6 0.8 1.0 Carbon (%) Elongation(%) 0 20 40 60 80 100 Izodimpactenergy(Nm) 140 120 100 80 60 40 Normalized Annealed Low carbon Medium carbon High carbon

- 27. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Annealed Stainless Steels Ultimate Tensile Yield AISI Strength Strength Elongation Characteristics and Typical (UNS) (MPa) (MPa) (%) Applications 303 (S30300) 550-620 240-260 50-53 Screw-machine products, shafts, valves, bolts, bushings, and nuts; aircraft fittings; rivets; screws; studs. 304 (S30400) 565-620 240-290 55-60 Chemical and food-processing equipment, brew- ing equipment, cryogenic vessels, gutters, down- spouts, and flashings. 316 (S31600) 550-590 210-290 55-60 High corrosion resistance and high creep strength. Chemical and pulp-handling equipment, photo- graphic equipment, brandy vats, fertilizer parts, ketchup-cooking kettles, and yeast tubs. 410 (S41000) 480-520 240-310 25-35 Machine parts, pump shafts, bolts, bushings, coal chutes, cutlery, fishing tackle, hardware, jet en- gine parts, mining machinery, rifle barrels, screws, and valves. 416 (S41600) 480-520 275 20-30 Aircraft fittings, bolts, nuts, fire extinguisher in- serts, rivets, and screws. TABLE 3.4 Room-Temperature Mechanical Properties and Typical Applications of Annealed Stainless

- 28. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tool & Die Materials TABLE 3.5 Basic Types of Tool and Die Steels. Type AISI High speed M (molybdenum base) T (tungsten base) Hot work H1 to H19 (chromium base) H20 to H39 (tungsten base) H40 to H59 (molybdenum base) Cold work D (high carbon, high chromium) A (medium alloy, air hardening) O (oil hardening) Shock resisting S Mold steels P1 to P19 (low carbon) P20 to P39 (others) Special purpose L (low alloy) F (carbon-tungsten) Water hardening W Process Material Die casting H13, P20 Powder metallurgy Punches A2, S7, D2, D3, M2 Dies WC, D2, M2 Molds for plastic and rubber S1, O1, A2, D2, 6F5, 6F6, P6, P20, P21, H13 Hot forging 6F2, 6G, H11, H12 Hot extrusion H11, H12, H13 Cold heading W1, W2, M1, M2, D2, WC Cold extrusion Punches A2, D2, M2, M4 Dies O1, W1, A2, D2 Coining 52100, W1, O1, A2, D2, D3, D4, H11, H12, H13 Drawing Wire WC, diamond Shapes WC, D2, M2 Bar and tubing WC, W1, D2 Rolls Rolling Cast iron, cast steel, forged steel, WC Thread rolling A2, D2, M2 Shear spinning A2, D2, D3 Sheet metals Shearing Cold D2, A2, A9, S2, S5, S7 Hot H11, H12, H13 Pressworking Zinc alloys, 4140 steel, cast iron, epoxy composites, A2, D2, O1 Deep drawing W1, O1, cast iron, A2, D2 Machining Carbides, high-speed steels, ceramics, diamond, cubic boron nitride TABLE 3.5 Typical Tool and Die Materials forVarious Processes.

- 29. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Non-Ferrous Alloys in Aircraft Engine FIGURE 3.34 Cross-section of a jet engine (PW2037) showing various components and the alloys used in making them. Source: Courtesy of United Aircraft Pratt & Whitney. Ti alloy fan Ti or Al alloy low-pressure compressor Ti or Ni alloy high-pressure compressor Ni alloy high-pressure turbine Ni alloy low-pressure turbine Turbine exhaust case Ni alloy Turbine blades Ni alloy Accessory section Al alloy or Fe alloy Inlet case Al alloy Ni alloy combustion chamber

- 30. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Aluminum Alloys Ultimate Tensile Yield Strength Elongation Alloy (UNS) Temper Strength (MPa) (MPa) in 50 mm (%) 1100 (A91100) O 90 35 35-45 1100 H14 125 120 9-20 1350 (A91350) O 85 30 23 1350 H19 185 165 1.5 2024 (A92024) O 190 75 20-22 2024 T4 470 325 19-20 3003 (A93003) O 110 40 30-40 3003 H14 150 145 8-16 5052 (A95052) O 190 90 25-30 5052 H34 260 215 10-14 6061 (A96061) O 125 55 25-30 6061 T6 310 275 12-17 7075 (A97075) O 230 105 16-17 7075 T6 570 500 11 8090 T8X 480 400 4-5 TABLE 3.7 Properties ofVarious Aluminum Alloys at Room Temperature

- 31. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Wrought Aluminum Alloys Characteristics∗ Corrosion Alloy Resistance Machinability Weldability Typical Applications 1100 A D-C A Sheet-metal work, spun hollow parts, tin- stock. 2014 C C-B C-B Heavy-duty forgings, plate and extrusions for aircraft structural components, wheels. 3003 A D-C A Cooking utensils, chemical equipment, pres- sure vessels, sheet-metal work, builders’ hard- ware, storage tanks. 5054 A D-C A Welded structures, pressure vessels, tube for marine uses. 6061 B D-C A Trucks, canoes, furniture, structural applica- tions. 7005 D B-D B Extruded structural members, large heat ex- changers, tennis racquets, softball bats. 8090 A-B B-D B Aircraft frames, helicopter structural compo- nents. ∗ From A (excellent) to D (poor). TABLE 3.8 Manufacturing Properties and Typical Applications of Wrought Aluminum Alloys.

- 32. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Magnesium Alloys Ultimate Tensile Yield Elongation Composition (%) Strength Strength in 50 mm Alloy Al Zn Mn Zr Condition (MPa) (MPa) (%) Typical Forms AZ31B 3.0 1.0 0.2 F 260 200 15 Extrusions H24 290 220 15 Sheet and plates AZ80A 8.5 0.5 0.2 T5 380 380 7 Extrusions and forgings HK31A∗ 0.7 H24 255 255 8 Sheet and plates ZK60A 5.7 0.55 T5 365 365 11 Extrusions and forgings ∗ HK31A also contains 3%Th. TABLE 3.9 Properties and Typical Forms ofVarious Wrought Magnesium Alloys.

- 33. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Copper & Brass Ultimate Type and Nominal Tensile Yield Elongation UNS Composition Strength Strength in 50 mm Number (%) (MPa) (MPa) (%) Typical Applications Oxygen-free 99.99 Cu 220-450 70-365 55-4 Bus bars, waveguides, hollow conductors, electronic lead in wires, coaxial cables and tubes, (C10100) microwave tubes, rectifiers. Red brass, 85.0 Cu 270-72 70-435 55-3 Weather stripping, conduit, sockets, (C23000) 15.0 Zn fasteners, fire extinguishers, condenser and heat-exchanger tubing. Low Brass, 80.0 Cu 300-850 80-450 55-3 Battery caps, bellows, musical instruments, (C24000) 20.0 Zn clock dials, flexible hose. Free-cutting 61.5 Cu, 340-470 125-310 53-18 Gears, pinions, automatic high-speed brass 3.0 Pb, screw-machine parts (C36000) 35.5 Zn Naval brass 60.0 Cu, 380-610 170-455 50-17 Aircraft turnbuckle barrels, balls, bolts, (C46400 to 39.25 Zn, marine hardware, valve stems, condenser C46700) 0.75 Sn plates. TABLE 3.10 Properties and Typical Applications ofVarious Wrought Copper and Brasses.

- 34. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Wrought Bronzes Ultimate Type and Nominal Tensile Yield Elongation UNS Composition Strength Strength in 50 mm Number (%) (MPa) (MPa) (%) Typical Applications Architectural 57.0 Cu, 415 140 30 Architectural extrusions, storefronts, bronze 3.0 Pb, (as extruded) thresholds, trim, butts, hinges. (C38500) 40.0 Zn Phosphor 95.0 Cu, 325-960 130-550 64-2 Bellows, clutch disks, cotter pins, bronze, 5% A 5.0 Sn, diaphragms, fasteners, wire brushes, (C51000) trace P chemical hardware, textile machinery. Free-cutting 88.0 Cu, 300-520 130-435 50-15 Bearings, bushings, gears, pinions, shafts, phosphor 4.0 Pb, thrust washers, valve parts. bronze 4.0 Zn, (C54400) 4.0 Sn Low-silicon 98.5 Cu, 275-655 100-475 55-11 Hydraulic pressure lines, bolts, marine bronze, B 1.5 Si hardware, electrical conduits, heat- (C65100) exchanger tubing. Nickel- 65.0 Cu, 390-710 170-620 45-3 Rivets, screws, zippers, camera parts, silver, 65-18 17.0 Zn, base for silver plate, nameplates, (C74500) 18.0 Ni etching stock. TABLE 3.11 Properties and Typical Applications ofVarious Wrought Bronzes.

- 35. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Nickel Alloys Principal Ultimate Alloying Tensile Yield elongation Alloy Elements Strength Strength in 50 mm (Condition) (%) (MPa) (MPa) (%) Typical Applications Nickel 200 None 380-550 100-275 60-40 Chemical- and food-processing (annealed) industry, aerospace equipment, electronic parts. Duranickel 301 4.4 Al, 1300 900 28 Springs, plastics-extrusion (age hardened) 0.6 Ti equipment, molds for glass. Monel R-405 30 Cu 525 230 35 Screw-machine products, water- (hot rolled) meter parts. Monel K-500 29 Cu, 1050 750 20 Pump shafts, valve stems, springs. (age hardened) 3Al Inconel 600 15 Cr, 640 210 48 Gas-turbine parts, heat-treating (annealed) 8 Fe equipment, electronic parts, nuclear reactors. Hastelloy C-4 16 Cr, 785 400 54 High-temperature stability, (solution treated 15 Mo resistance to stress-corrosion and quenched) cracking. TABLE 3.12 Properties and Typical Applications ofVarious Nickel Alloys (All Alloy Names are Trade Names).

- 36. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Nickel-Base Superalloys Ultimate Tensile Yield Elongation Strength Strength in 50 mm Alloy Condition (MPa) (MPa) (%) Typical Applications Astroloy Wrought 770 690 25 Forgings for high-temperature applications. Hastelloy X Wrought 255 180 50 Jet-engine sheet parts. IN-100 Cast 885 695 6 Jet-engine blades and wheels. IN-102 Wrought 215 200 110 Superheater and jet-engine parts. Inconel 625 Wrought 285 275 125 Aircraft engines and structures, chemical-processing equipment. Inconel 718 Wrought 340 330 88 Jet-engine and rocket parts. MAR-M 200 Cast 840 760 4 Jet-engine blades. MAR-M 432 Cast 730 605 8 Integrally cast turbine wheels. Ren´e 41 Wrought 620 550 19 Jet-engine parts. Udimet 700 Wrought 690 635 27 Jet-engine parts. Waspaloy Wrought 525 515 35 Jet-engine parts. TABLE 3.13 Properties and Typical Applications ofVarious Nickel-Base Superalloys at 870°C (1600°F) (All Alloy Names Are Trade Names)

- 37. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Titanium Alloys Ultimate Nominal Tensile Yield Elon- Composi- Con- Temp Strength Strength gation tion (%) UNS dition (◦ C) (MPa) (MPa) (%) Typical Applications 99.5 Ti R50250 Annealed 25 330 240 30 Airframes; chemical, desalination, 300 150 95 32 and marine parts; plate-type heat exchangers. 5 Al, 2.5 Sn R54520 Annealed 25 860 810 16 Aircraft-engine compressor blades 300 565 450 18 and ducting; steam-turbine blades. 6 Al, 4V R56400 Annealed 25 1000 925 14 Rocket motor cases; blades and 300 725 650 14 disks for aircraft turbines and 425 670 570 18 compressors; orthopedic 550 530 430 35 implants; structural forgings; Solution 25 1175 1100 10 fasteners. + age 300 980 900 10 13 V, 11 Cr, R58010 Solution 25 1275 1210 8 High-strength fasteners; aerospace 3Al + age 425 1100 830 12 components; honeycomb panels. TABLE 3.14 Properties and Typical Applications of Wrought Titanium Alloys.