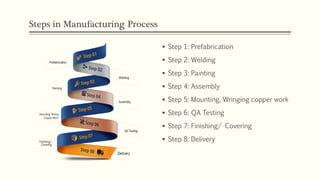

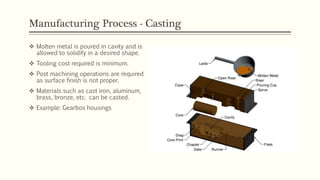

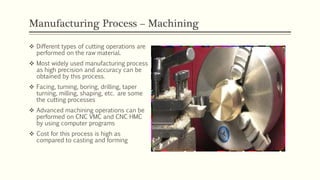

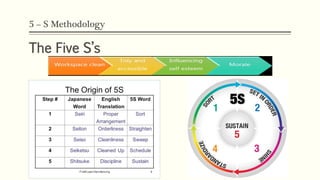

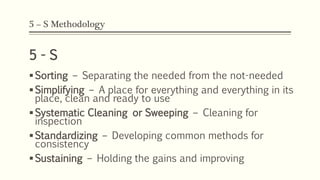

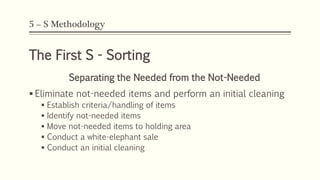

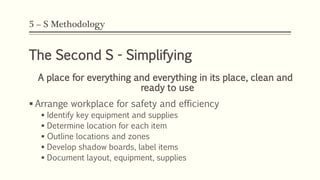

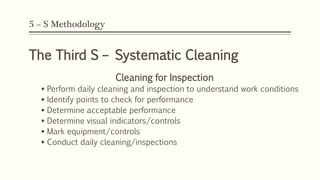

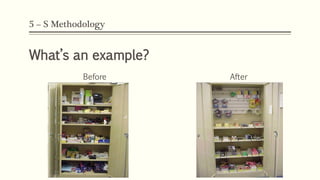

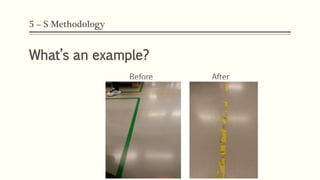

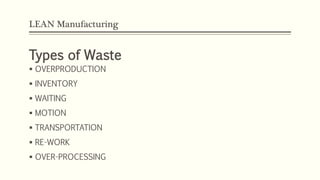

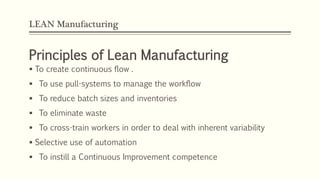

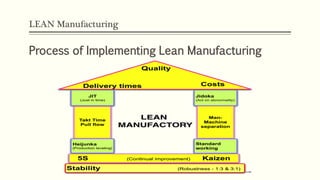

Manufacturing involves transforming raw materials into finished goods through various processes. The key steps in manufacturing include prefabrication, welding, painting, assembly, testing, finishing and delivery. Manufacturing processes can be classified as casting, forming and machining. Implementing lean manufacturing principles such as reducing waste, batch sizes and inventories can improve productivity, quality and reduce costs. The 5S methodology is a common starting point that involves sorting, simplifying, sweeping, standardizing and sustaining work areas to increase organization and efficiency.