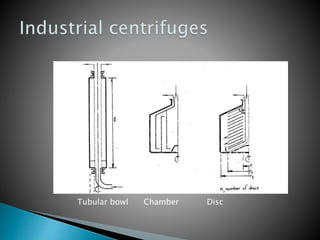

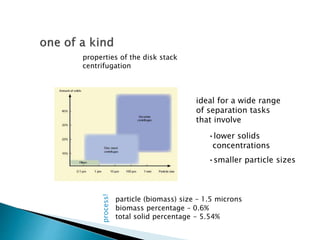

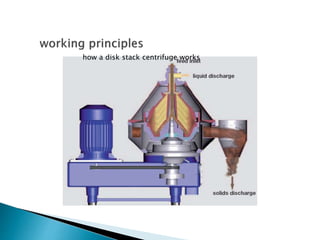

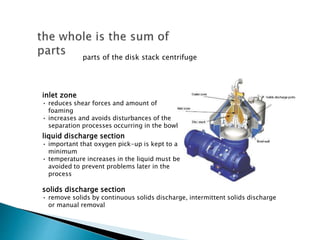

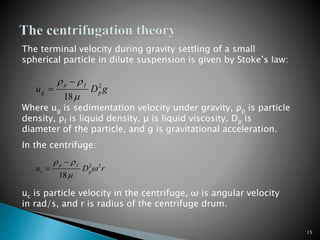

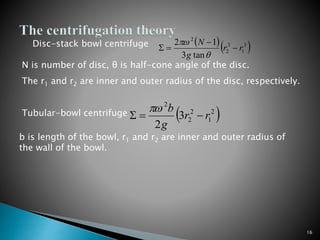

This document discusses different types of centrifugation used in industrial processes. It describes tubular bowl centrifuges and disc-stack bowl centrifuges. Tubular bowl centrifuges can generate high centrifugal forces and are widely used in food and pharmaceutical industries. Disc-stack bowl centrifuges are common in bioprocesses and can generate forces between 5000-15000 G, separating particles as small as 5 microns. The document also discusses how disc-stack centrifuges work continuously to separate solids and liquids using extremely high rotational speeds.