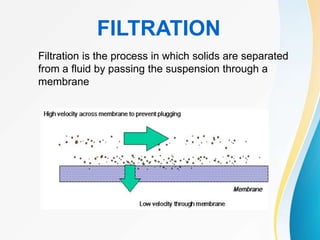

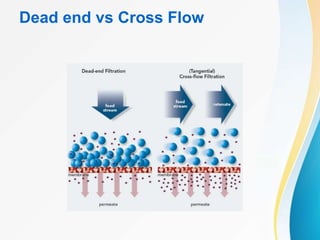

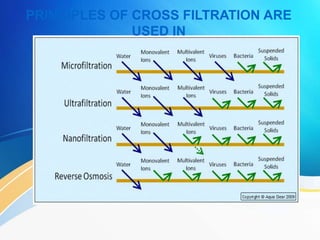

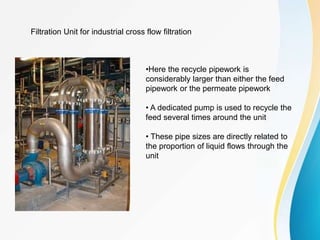

This document discusses cross flow filtration, which separates solids from fluids using a semipermeable membrane while preventing filter cake formation. Cross flow filtration maintains a constant filtration rate by keeping the process feed in a mobile slurry form suitable for further processing. It allows for relatively high solids loads to be operated continuously without blinding the filter. The document outlines the principles, advantages over dead-end filtration, techniques to improve it like backwashing, and applications in reverse osmosis, nanofiltration, ultrafiltration, and microfiltration such as water treatment, sterilization, dairy processing, and more.