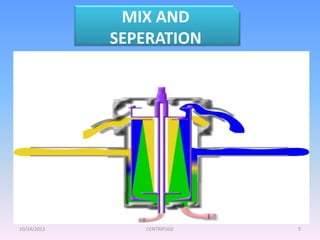

A centrifugal extractor uses the rotation of an internal rotor to mix two immiscible liquids and separate them using centrifugal force. As the liquids enter the rotor, they are accelerated toward the wall and separation begins based on density differences. Weirs allow each separated phase to exit individually and flow by gravity to downstream stages without pumps. Configurations include mixing and separating the phases, separating pre-mixed liquids via direct feed, and multi-stage processing for continuous solvent extraction.