This document provides information about centrifugation including its definition, principle, applications, types, and instruments. It can be summarized as follows:

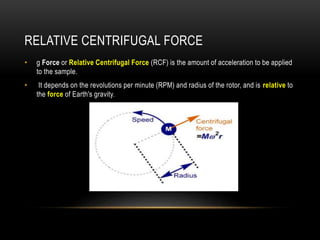

Centrifugation uses centrifugal force to separate particles in a solution based on properties like size, density, and viscosity. It works by spinning the solution at high speeds, which forces denser particles to settle out. Common applications include separating drugs, proteins, and analyzing suspensions and emulsions in pharmaceutical and biomedical fields. There are two main types - sedimentation centrifuges separate based on density differences, while filtration centrifuges use a membrane to retain solids. Common instruments described include perforated basket, non-perforated basket, semi-continuous, and super centrifuges.