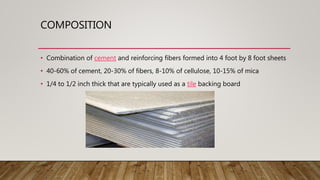

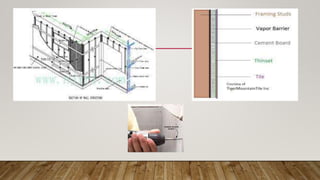

Cement boards are composed of cement, reinforcing fibers, cellulose, and mica formed into thick sheets. They are durable, resistant to termites and rot, and require little maintenance once installed. Cement boards are installed with corrosion resistant fasteners and filled joints, and are being increasingly used in prefabricated homes in Nepal due to benefits like earthquake resistance, fire resistance, and reduced construction time and costs.