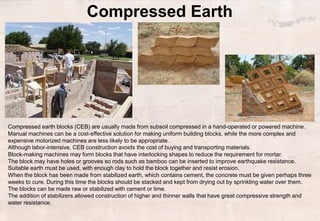

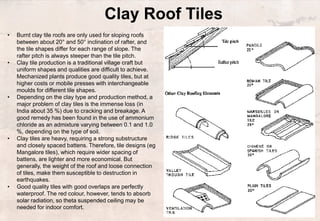

This document provides an overview of various earth construction techniques. It begins by explaining that earth structures are made primarily from soil and may include additives like straw or cement to add strength. Common earth building materials include mud, cob, adobe bricks, rammed earth, and compressed earth blocks.

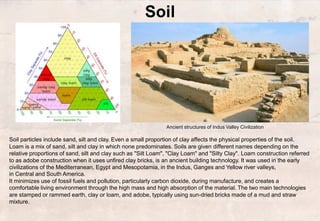

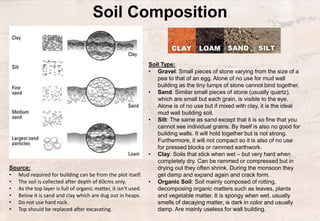

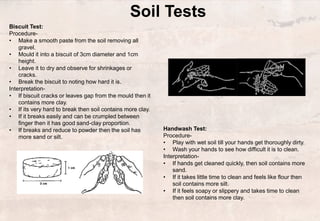

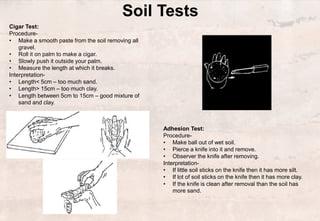

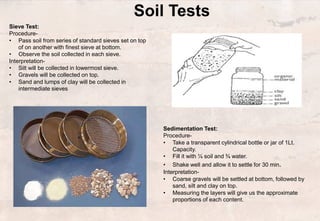

The document then discusses soil composition and types, explaining that clay, silt, sand and gravel can be used alone or combined in earth construction. It provides details on testing soil properties through methods like the biscuit test. Stabilizers like lime, cement or plant fibers can be added to improve soil suitability.

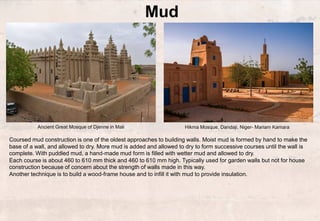

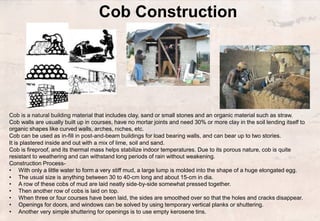

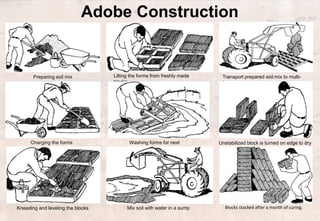

Construction techniques covered include mud construction, cob building, adobe brick making, wattle and daub,