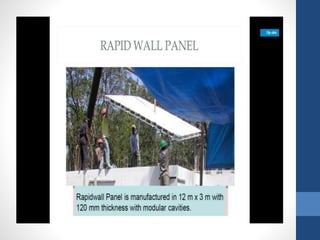

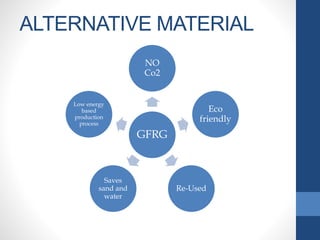

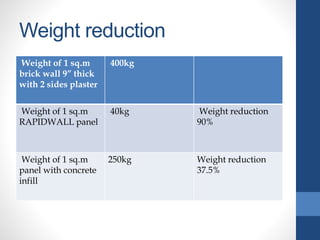

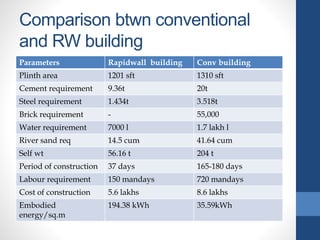

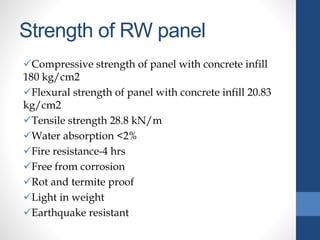

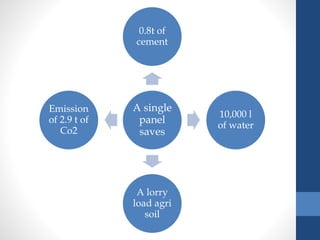

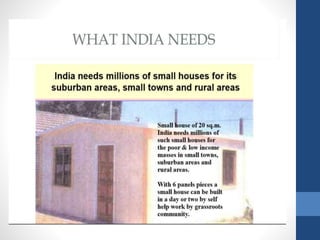

Fibre reinforced gypsum panels (GFRG panels) are an alternative and eco-friendly building material manufactured using a gypsum core. Originally developed in Australia, GFRG panels can be used for load bearing walls up to 10 stories high and offer rapid construction. Compared to conventional building materials like bricks and cement, GFRG panels reduce CO2 emissions, conserve scarce resources like sand and water, require less energy to produce, and allow for faster construction with fewer workers. GFRG panels are strong, lightweight, fire resistant, termite proof and can reduce a building's weight by up to 90% compared to conventional brick walls.