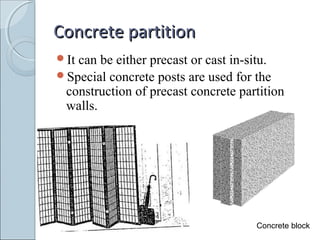

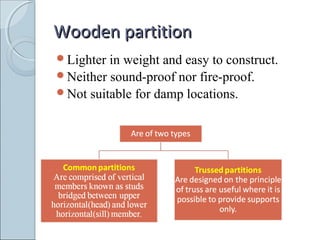

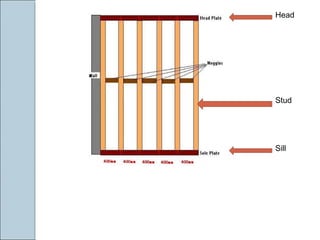

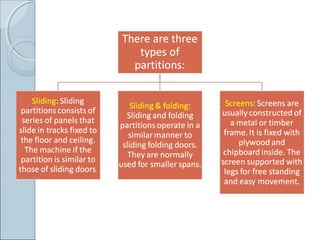

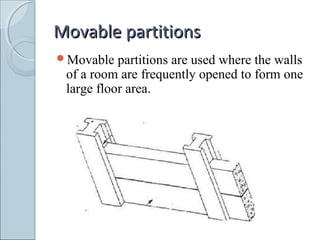

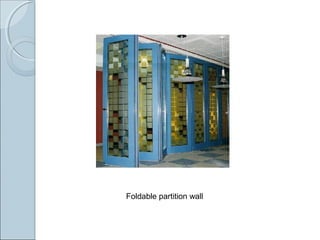

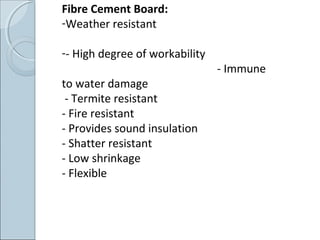

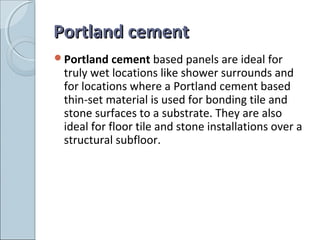

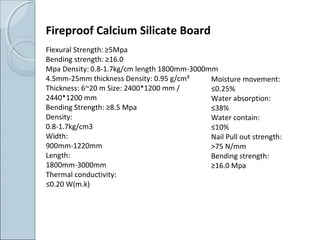

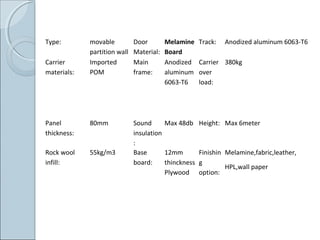

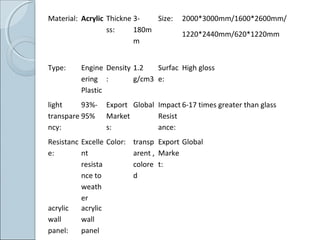

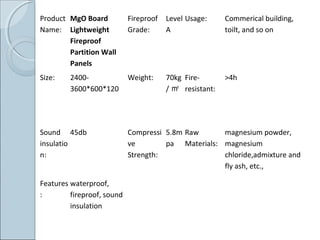

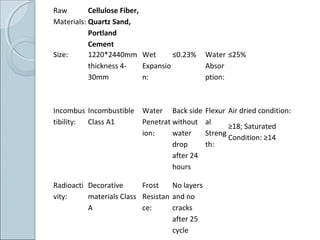

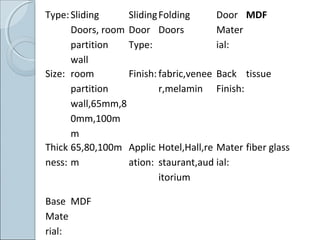

Partition walls are non-load bearing walls that divide rooms or spaces. They provide privacy, occupy less space, and are lighter and cheaper than load-bearing walls. Good partition walls are thin, provide sound and sight privacy, and are made of durable, fire resistant and insulated materials. Common materials for partition walls include brick, hollow blocks, concrete, glass, wood, strawboard, plaster, metal and drywall. Movable and portable partition walls allow spaces to be reconfigured easily.