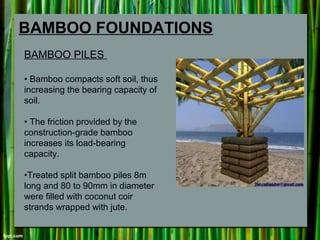

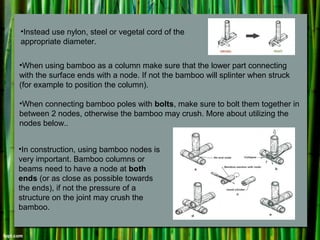

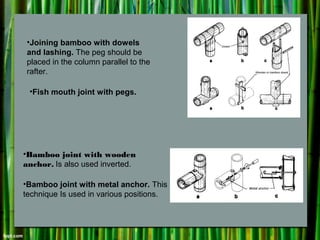

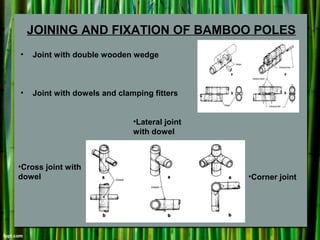

Bamboo is a fast-growing woody grass known for its high strength-to-weight ratio, flexibility, and compressive strength, making it suitable for structural applications in both residential and commercial construction. Various uses of bamboo include foundations, roofing, walling, and flooring, with specific joinery techniques needed to ensure structural integrity. Proper age, treatment, and cutting methods are essential for effective bamboo construction.