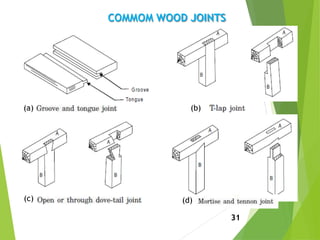

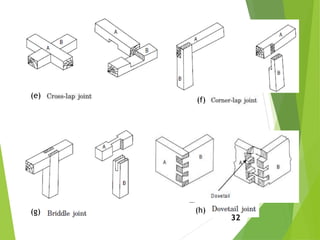

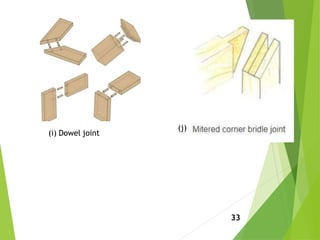

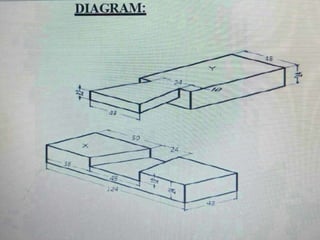

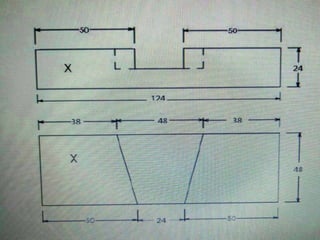

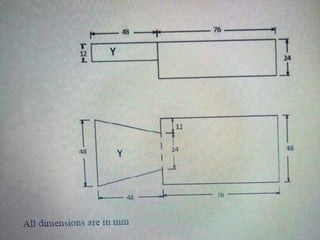

1. The document provides details about three carpentry experiments: making a sawing and grooving joint, a T-lap joint, and a dovetail lap joint from wood pieces.

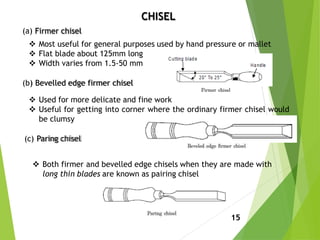

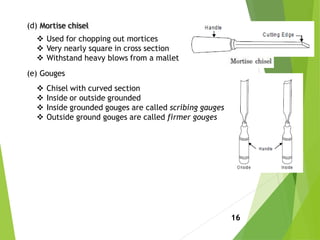

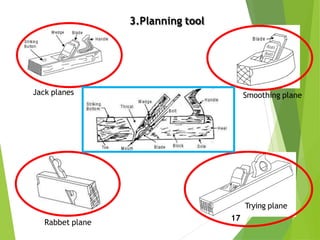

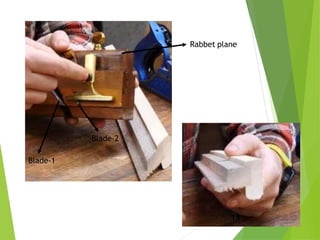

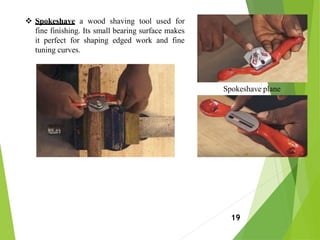

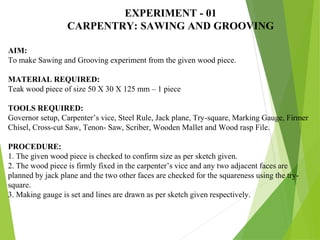

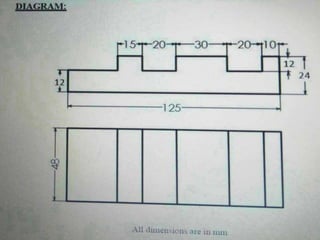

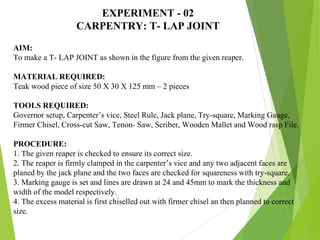

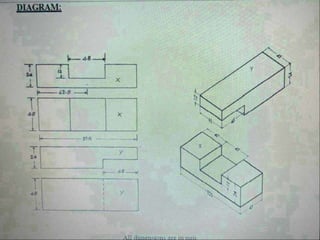

2. It describes the materials, tools, and step-by-step procedures to make each joint, including marking, sawing, chiseling, planning and finishing the wood pieces.

3. The goals of the experiments are to learn how to properly make basic wood joints using tools such as saws, chisels, and planes while following safety precautions.