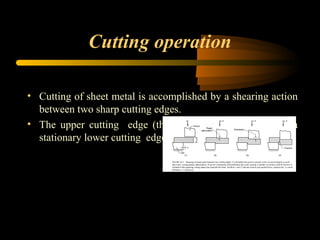

The document discusses sheet metal forming and cutting operations, including shearing, blanking, and punching, with applications in various industries such as construction, automotive, and aerospace. It provides engineering analysis on cutting parameters, including clearance between punch and die, as well as details on bending and drawing operations to create complex shapes. Additionally, it touches on advanced processes like stretch forming and spinning for producing axially symmetric parts.