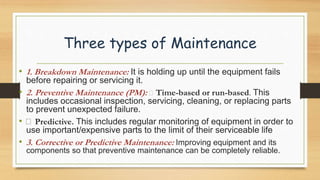

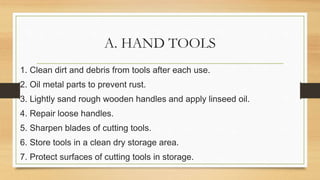

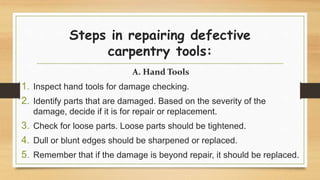

The document discusses preventive maintenance of carpentry tools. It outlines three types of maintenance: breakdown, preventive, and predictive. Preventive maintenance includes regular inspection, cleaning, and replacing parts to prevent failure. The document then provides steps for conducting basic preventive maintenance of hand tools and electric tools. This includes cleaning tools, inspecting cords, lubricating moving parts, and following maintenance schedules. Finally, it outlines steps for repairing defective tools, which involves inspecting for damage, identifying damaged parts, tightening loose parts, sharpening dull blades, and replacing parts that cannot be repaired.