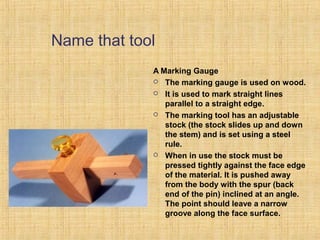

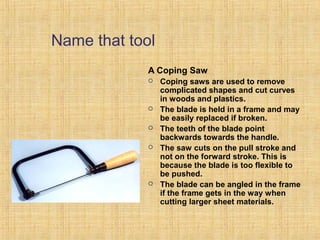

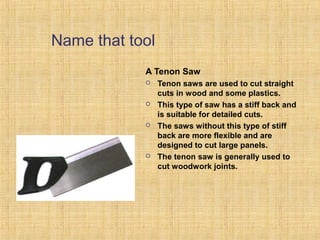

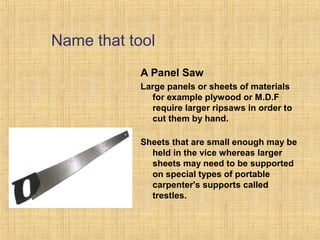

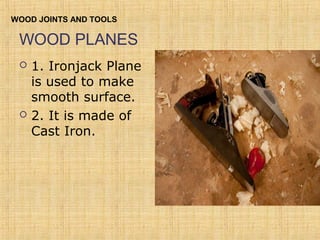

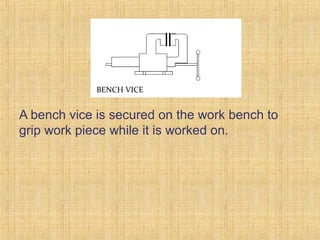

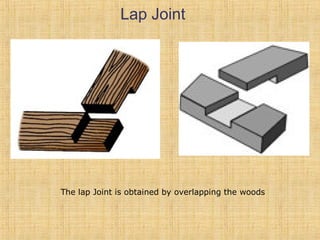

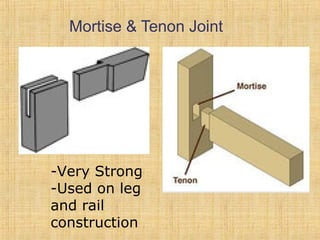

The document discusses various carpentry tools and wood joints. It provides details on 8 common tools: try square, steel rule, marking gauge, coping saw, tenon saw, panel saw, ironjack plane, and bench vice. It describes what each tool is used for and key features. The document also briefly explains two types of wood joints - the lap joint and mortise & tenon joint. It notes the mortise & tenon joint is very strong and often used in leg and rail construction.