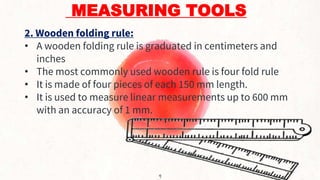

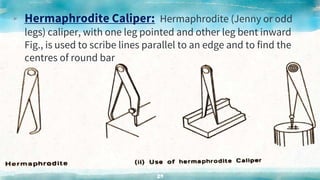

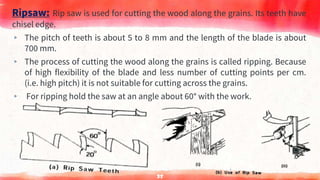

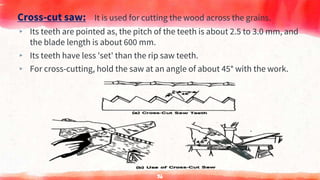

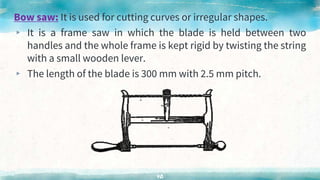

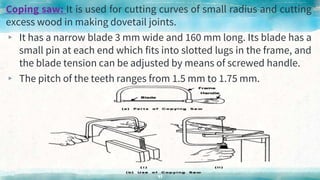

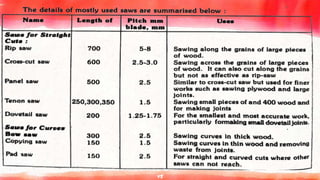

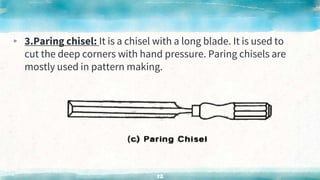

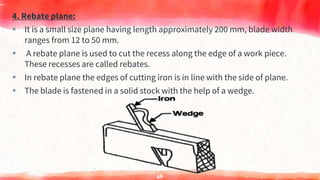

This document provides information about carpentry tools used in woodworking. It discusses various measuring tools like steel rules, folding rules, and steel tapes. Marking tools include straight edges, try squares, marking gauges, and dividers. Cutting tools include handsaws for ripping and cross-cutting wood. Chisels are used for shaping and paring wood. The document describes different saws, gauges, calipers and chisels used in carpentry and provides details about their specifications and uses. It aims to introduce the basic tools and operations in carpentry workshop.