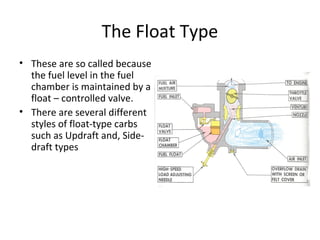

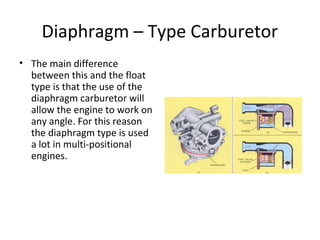

The document discusses carburetion in small engines. It describes the components of a small engine fuel system including the carburetor. The carburetor atomizes fuel into a fine spray and mixes it with air. It regulates the ratio of fuel to air and the amount of fuel-air mixture entering the combustion chamber. The ratio is controlled by needle valves and affects engine performance. It then discusses the principles of carburetor operation including how vacuum pulls fuel into the air stream and how choke valves and butterfly valves control the fuel-air ratio during starting and operation. Finally, it describes different types of carburetors including float, suction-lift, and diaphragm types.