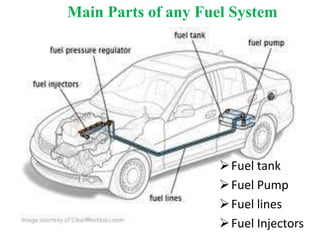

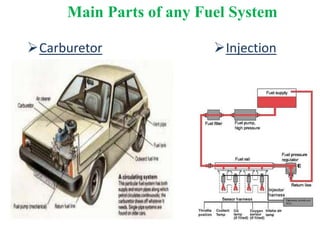

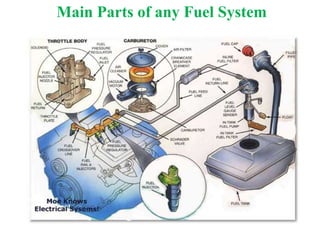

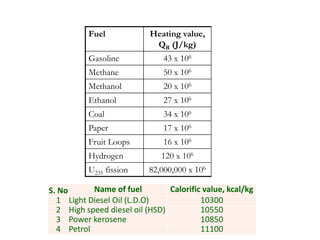

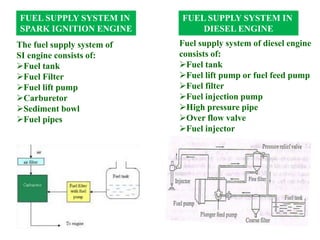

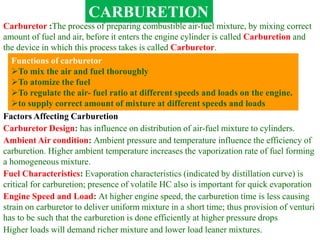

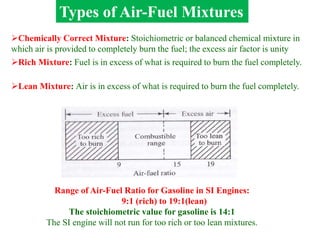

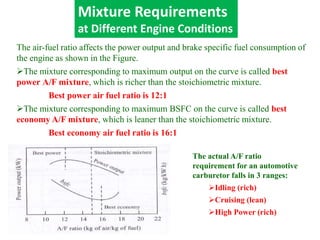

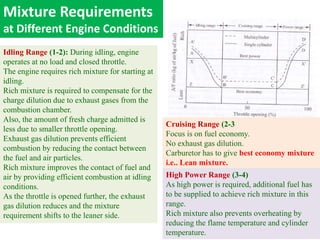

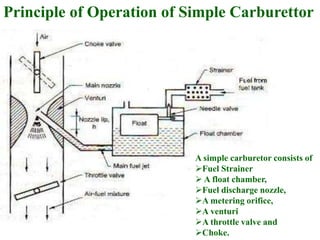

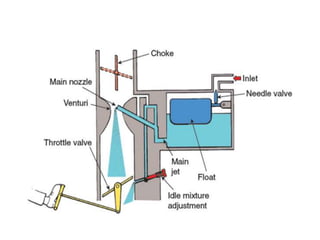

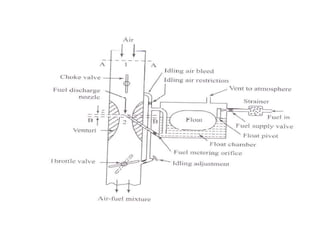

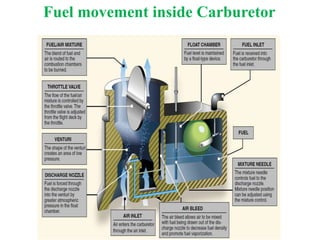

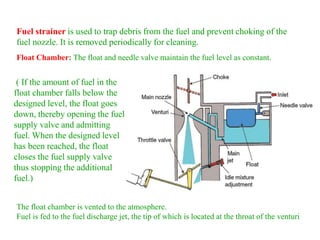

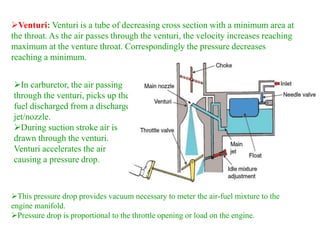

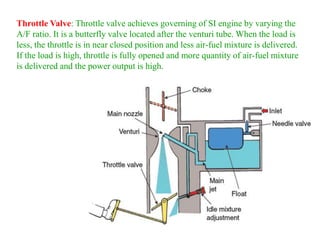

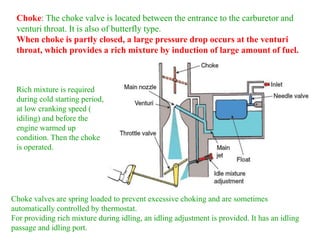

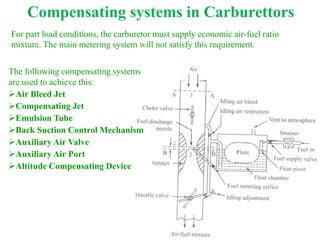

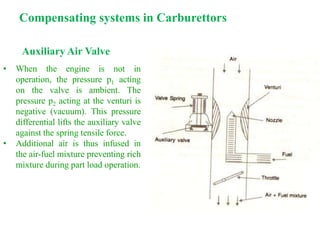

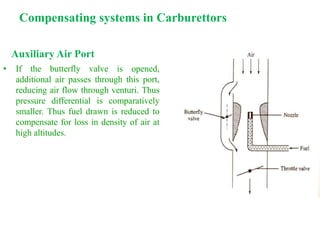

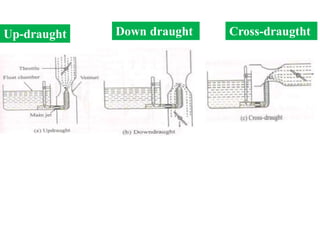

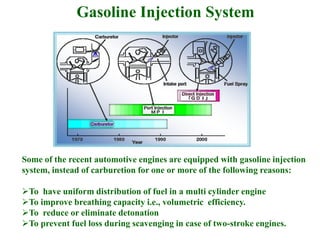

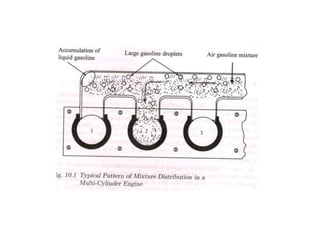

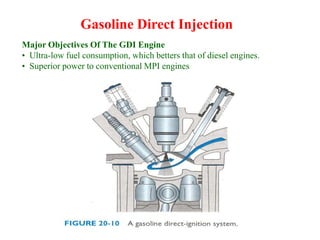

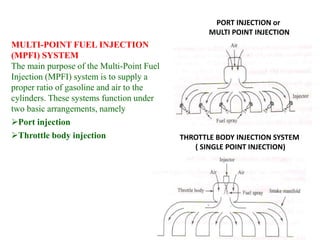

The document outlines the various fuel supply systems in internal combustion (IC) engines, including characteristics of efficient systems and parts like the carburetor and fuel injectors. It details the processes of carburetion, factors affecting air-fuel mixture ratios, and different types of carburetors and fuel injection systems. Additionally, it covers the principles of operation, compensating systems within carburetors, and the calibration of fuel supply systems for different engine conditions.